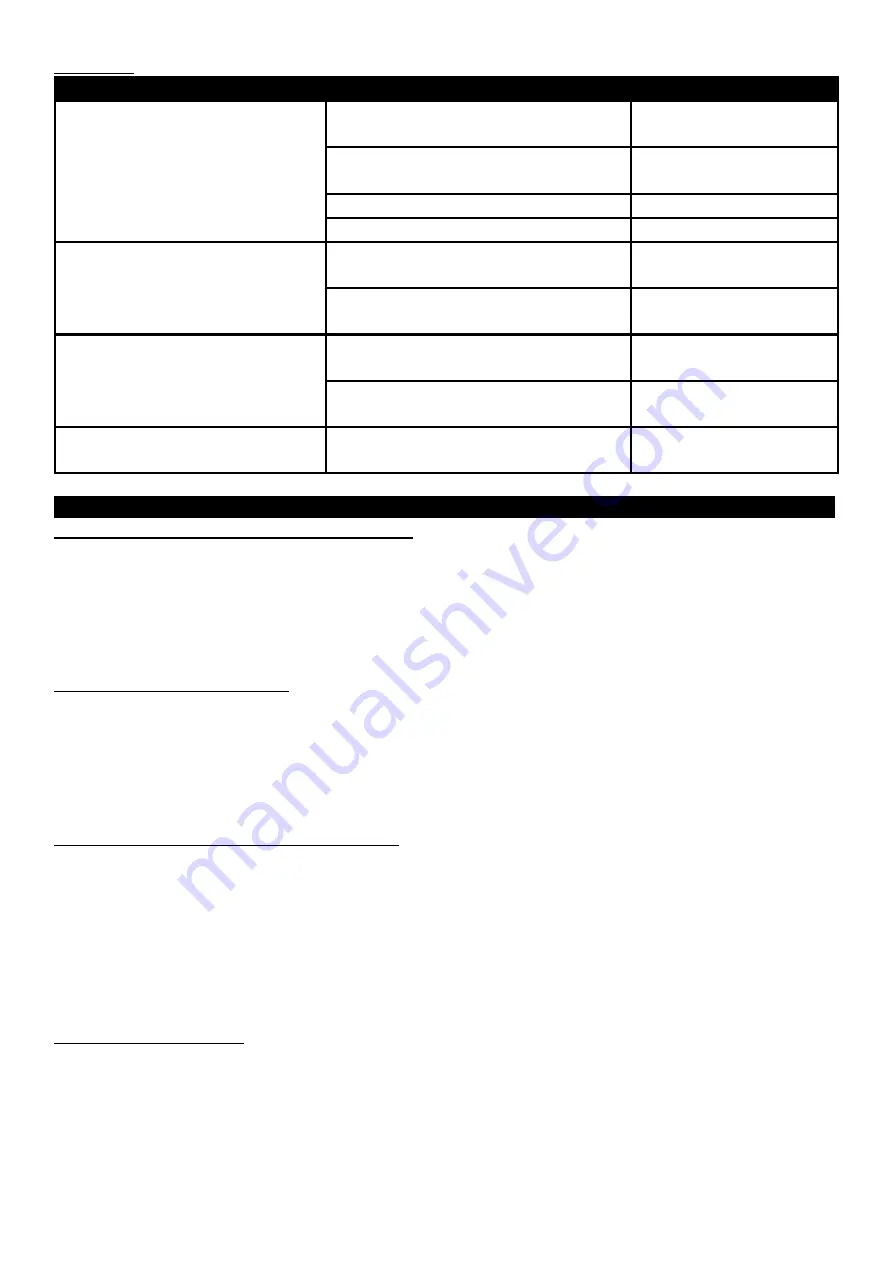

6. Dusting:

TROUBLE

CAUSE

REMEDIES

No dust discharge or discharge

intermittently

No dust gate can not be opened

Adjust the pull rod of the

dust gate

The dust or granule mix with foreign

body

Clean it

The dust or granule lumped

Break the lump

Wet dust or granule

Dry it

The dust gate not work properly

The dust gate can not be closed

Adjust the pull rod of the

dust gate

The dust gate is blocked up by foreign

matter

Clean it

Leakage of dust

The clamp plate of the chemical tank

bottom loosened

Tighten it

The sealing gasket of the dusting lid

damaged

Change it with new one

The discharge rate out of control

The control device of dust gate can not

work properly

Remedy it

MAINTENANCE AND ENVIROMENTAL PROTECTION

......................................................

1. Technical maintenance on spraying assembly:

- After spraying, clean out any residual spray mixture or dust in the chemical tank. Wash the tank and all

other parts.

- After dusting or granules spreading, clean the dust gate and chemical tank inside and outside.

- After operation, loosen the chemical tank lid. (4) After cleaning, the machine runs at low speed for 2—3

minutes

2. Maintenance on fuel system:

- The fuel mix with dust or water is one of main cause of the engine trouble, so the fuel system should be

cleaned very often.

- If the residual fuel remains in the fuel tank and carburetor for a long time, the residual fuel would be

glued and the fuel circuit clogged, thus causing the engine not to working properly. So as the machine

works for one week. All of the fuel should be discharged.

3. Maintenance on air filter and sparking plug:

- After the operation each day, wash the filter, if the chemicals adhere to sponge, it would deduce the

engine power, please pay attention especially.

- After wash the sponge with petrol, squeeze the petrol then fix the sponge in.

- The suitable clearance of sparking plug is 0.6—0.7mm, please check the clearance often, if it is too big or

too small, adjust it properly.

- The sparking plug model of this machine is 4106J. Do not use other model. If it is necessary for change,

you may buy it form local agricultural machinery department or plant protection department.

4. Deposit for along time:

- Clean the outside of the machine. Coat the anti-rust oil to the surface of metal.

- Take down the sparking plug. Feed 15—20g mobile oil into cylinder, the mobile oil should be specially

used for two-stroke petrol engine. Raise the piston to upper terminal point, then fix sparking plug.

- Screw out the two wing screws. Take off the machine tank. Clean the dust gate and the surface inside and

outside of chemical tank. If the residual chemical remains in the dust gate, the dust gate will not properly

and the leakage of dust will occur seriously. Then fit the chemical tank on and the loosen the tank lid.

- Take off the spray unit and wash it and then store additionally.