Striem

3100 Brinkerhoff

Kansas City, KS 66115

Tel: 913-222-1500

Fax: 913-291-0457

www.

striemco.com

Made in the U.S.A

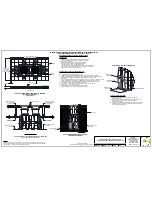

FLOW

Set unit on level solid surface as close as

possible to fixtures being served. If unit is

to be installed below grade refer to below

grade installation instructions. (sheet #3)

Isometric View

Connect inlet and outlet drainage lines to

unit. Mechanically couple pipes to

unit.

Do not solvent weld

.

Top View

FLOW

FLOW

LB-275 SHOWN

Locking collar

Cover

Closed top

inlet diffuser

to provide sewer

gas trap

Adapter

Vent

GENERAL NEUTRALIZATION TANK INSTALLATION INSTRUCTIONS

(LB-275 SHOWN)

OPERATION:

Striem Lab Basins are designed to neutralize or dilute (based on specific requirements) chemical

wastewater and bring it to a more neutral state, rendering it acceptable for local wastewater treatment

facilities. Diffusion Flow design and extended flow path improve neutralization over traditional cylindrical

tanks. The most common neutralization situation occurs when acidic waste is filtered through a

neutralizing media, most often a specific size and composition of limetsone.

Wastewater flows through the inlet connection and is forced to the bottom of the unit via diffuser. For

neutralization tanks, the wastewater is then filtered through a neutralizing agent (Limestone with a

Calcium Carbonate level of 90% or better is most common) and then exits the chemical waste tank

though the outlet. For dilution tanks, intermittent chemical waste moves through a majority water solution

from previous batches and then exits the chemical waste tank through the outlet.

MAINTENANCE

Remove the cover(s).

1.

For the best maintenance contact a professional sewer and drain contractor. Proper mainentance is

2.

essential to keep the Neutralization Tank in proper working order. Debris entering the tank from a sink or lab

station may plug the invert or foul the neutralizing agent. If limestone is to be used as a neutralizing agent,

the limestone will be depleted as it works to neutralize the incoming effluent. Once the limestone is depleted,

the tank should be cleared of sludge, sediment, and debris before adding the new neutralizing agent.

A

qualified professional should be responsible for the analysis of effluent, inspection, maintenance,

and replacement of neutralizing agent.

Observe a regular schedule of maintenance. Start by inspecting the new system every month to three

3.

months until a proper schedule can be established. The frequency will depend on the tank capacity and the

content of the chemical waste passing through the system.

Debris and sludge must be cleaned out periodically to allow the free flow of water through the tank. If it is

4.

determined that the Neutralization Tank or System will encounter large amounts of debris or sediment,

specify a Striem Solids Interceptor.

As the limestone is depleted, the tank should be cleared of sludge, sediment, and debris before new

5.

neutralizing agent is added. When limestone begins to foul, it often dissipates into a muddy substance and

the level of the stone will begin to recede. When the stone is mostly fouled, the tank should be flushed with

fresh water, the fouled debris removed from the tank, the tank cleaned, and new limestone added.

TROUBLESHOOTING TIPS:

Slow drainage is course for immediate inspection! Call a professional contractor for assistance. Call Striem for

details on tank specifications.

LAB BASIN SERIES INSTALLATION,

OPERATION AND MAINTENANCE GUIDE

ECO:

10/22/18

MJ

REV:

DATE:

DWG BY:

DESCRIPTION:

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF

STRIEM, LLC.

ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF

STRIEM, LLC.

IS

PROHIBITED.

NOTES:

Striem Lab Basins are not to be installed in any other manner except as shown. Consult local

codes for separate trapping requirements, cleanout locations and additional installation instructions

Vent required on outlet pipe only if outlet diptube is present.

SHEET NUMBER:

2 of 6