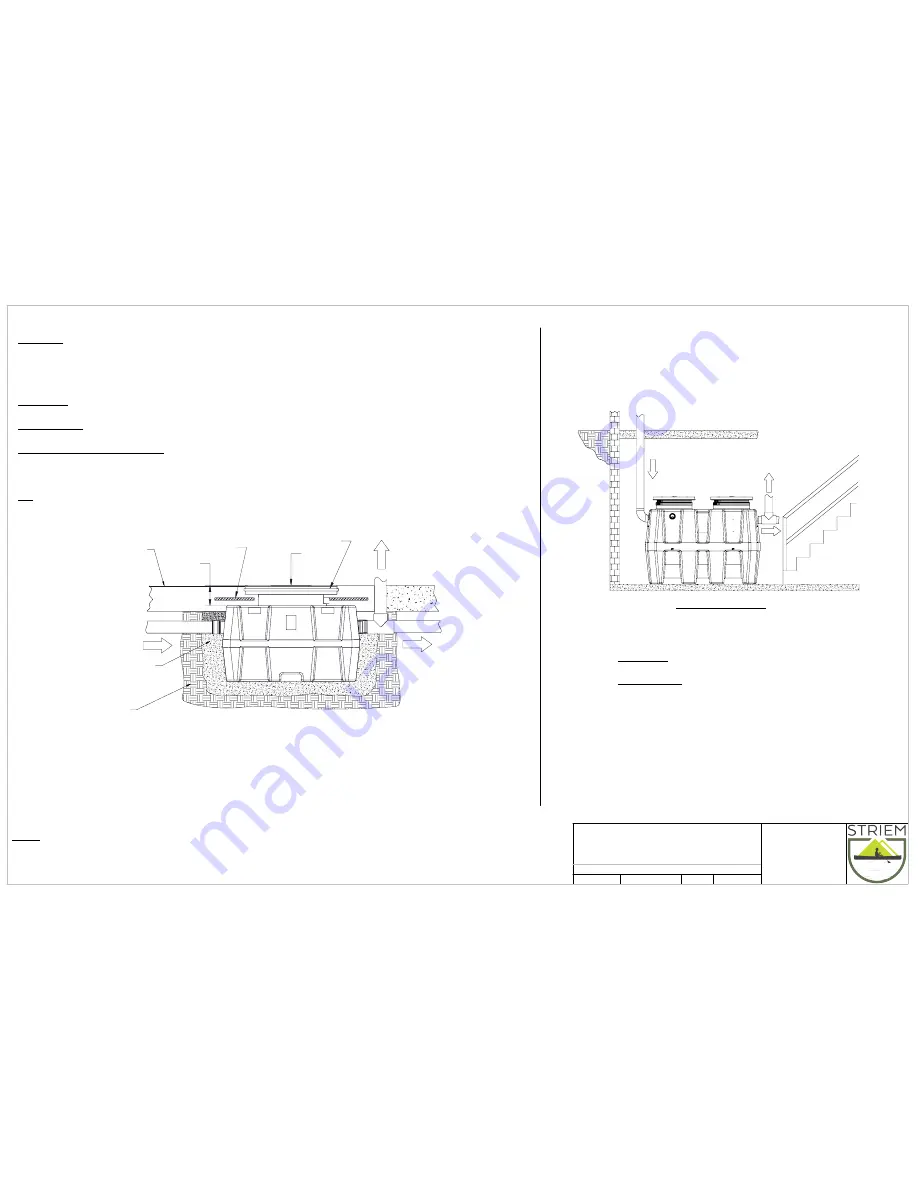

ON-THE-FLOOR DETAIL

(OS-100 SHOWN)

SHOP

FLOW

FLOW

FLOW

FLOW

Max. load

2,500 lb.

OS-25 Shown with riser

Rebar

Riser (sold separately)

16" Max.

VENT

If concrete slab falls within body of unit, reinforce with rebar,

extending 6" beyond footprint of unit to connect main floor slab.

Concrete

Crushed aggregate or sand backfill

Native soil

Striem

3100 Brinkerhoff

Kansas City, KS 66115

Tel: 913-222-1500

Fax: 913-291-0457

www.

striemco.com

Made in the U.S.A

INTERIOR BELOW GRADE INSTALLATION INSTRUCTIONS

(OS-15, OS-25)

EXCAVATION

Install unit(s) as close as possible to fixtures being serviced.

1.

Width and length of excavation shall be minimum 6" greater

2.

than the tank on all sides.

Depth of excavation shall be 6" deeper than tank bottom.

3.

Set the tank in well-packed crushed aggregate #7 backfill material

4.

approximately 3/4" size rock, or sand, with no fines.

CONNECTIONS

Connect waste piping to the unit.

1.

SET OIL DRAW OFF

If unit is ordered with optional oil draw off connection, see sheet 5 for correct settings.

1.

BACKFILLING & FINISHED CONCRETE SLAB

Before backfilling and pouring of slab secure cover(s) to the unit(s).

1.

Backfill using crushed aggregate #7 backfill material approximately 3/4" size rock or sand

2.

with no fines.

3. Place 6" aggregate base under slab.

Note

Models OS-15 and OS-25 cannot be installed flush with floor. A riser must be used for below

grade installations.

INTERIOR ABOVE GRADE INSTALLATION INSTRUCTIONS

(OS-15, OS-25, OS-35, OS-50, OS-75, OS-100, OS-500)

Install unit(s) as close as possible to fixtures/drains being serviced.

CONNECTIONS

Connect waste piping to the unit.

SET OIL DRAW OFF

If unit is ordered with optional oil draw-off connection, see sheet #5 for correct settings.

VENT

OS & OCT SERIES INSTALLATION,

OPERATION AND MAINTENANCE GUIDE

ECO:

8/15/18

MJ

REV:

DATE:

DWG BY:

DESCRIPTION:

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF

STRIEM, LLC.

ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF

STRIEM, LLC.

IS

PROHIBITED.

NOTES:

Striem oil separators are rated and manufactured with an internal flow control system already in

place. They do not require an external flow control system or air intake vent.

Striem oil separators are not to be installed in any other manner except as shown. Consult local

codes for separate trapping requirements, cleanout locations and additional installation instructions.

SHEET NUMBER:

4 of 7