Clean out to grade

on inlet pipe of each

unit (by others)

Clean out to grade

on outlet pipe of each

unit (by others)

Risers to grade

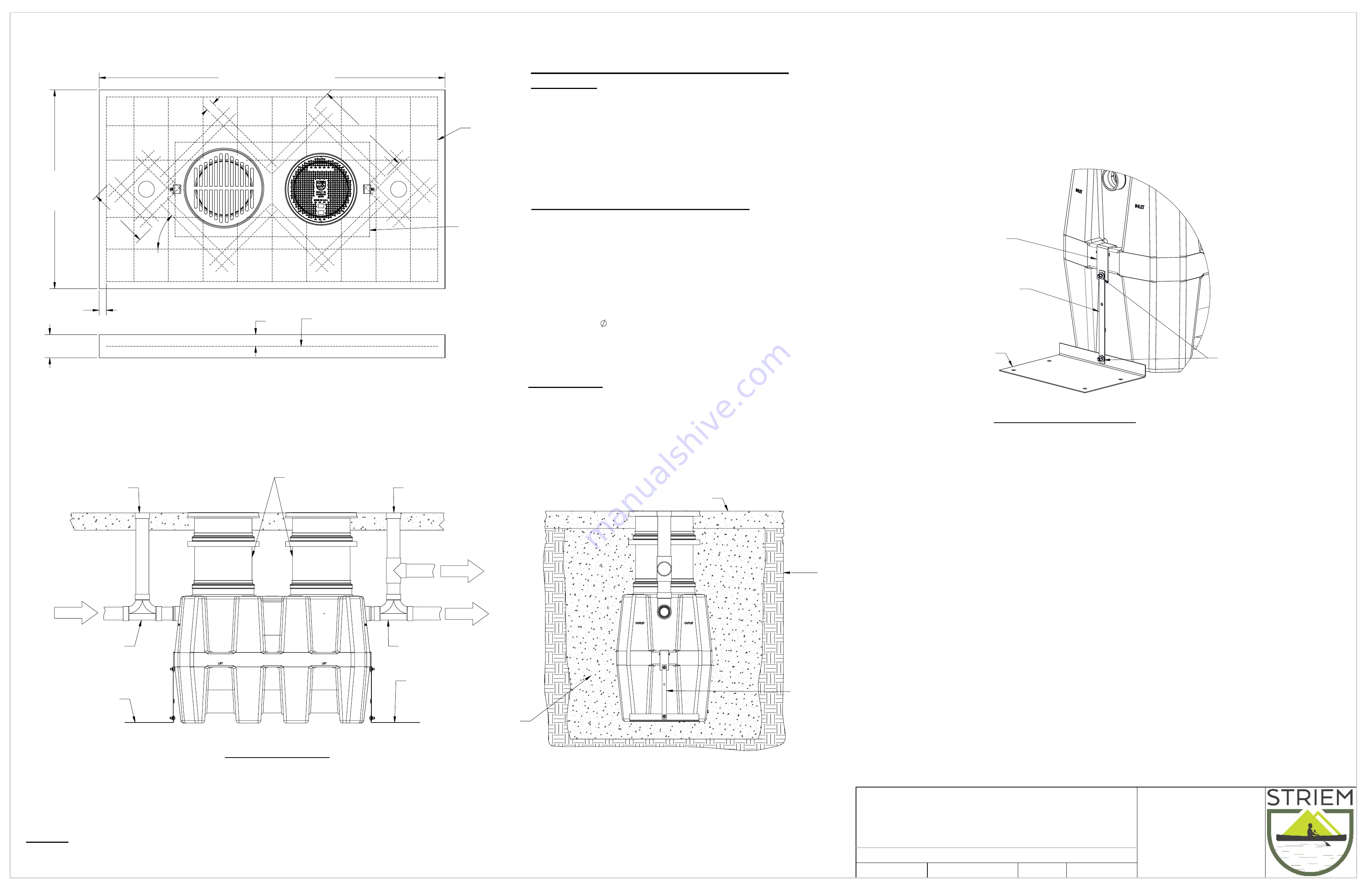

EXCAVATION AND BACKFILL DETAIL

(INTERIOR OR EXTERIOR)

2-Way cleanout

tee (by others)

2-Way cleanout

tee (by others)

SIDE VIEW DETAIL

Optional Anchor kit

see detail

Optional Anchor kit

see detail

Concrete slab

Native soil

Crushed aggregate

or sand

Optional Anchor kit

see detail

FLOW

FLOW

Striem

3100 Brinkerhoff

Kansas City, KS 66115

Tel: 913-222-1500

Fax: 913-291-0457

www.

striemco.com

Made in the U.S.A

30"

60"

4"

the unit footprint

Concrete Pad

must extend

18" outside

45.00°

2 1/2" Min.

18" outside the unit footprint

Concrete Pad must extend

8"

4"

Rebar

Finished Grade

Rebar

CB-275-S

Shown

CONCRETE SLAB DETAIL FOR TRAFFIC LOADING

(INTERIOR OR EXTERIOR)

(SI-UPC-1016 Shown)

Top View

Elevation View

For unit details see specification sheet for selected unit

(Connecting pipe and fittings by others)

VENT

CONNECTIONS

Connect waste piping to the unit.

1.

BACKFILLING & FINISHED CONCRETE SLAB

Preparation of sub grade per geotech recommendations.

1.

Stabilize and compact sub grade to 95% proctor.

2.

Fill tank with water before backfilling to prevent float out during piping installation.

3.

Before backfilling and pouring of slab secure cover(s) and riser/s (if necessary) to the unit(s)

4.

Backfill using crushed aggregate material approximately 3/4" size rock, or sand,

5.

with no fines.

6. Place 6" aggregate base under slab. Aggregate should be 3/4" size rock, or sand, with no fines.

7. Thickness of concrete around cover to be determined by specifying engineer. If traffic

loading is required the concrete slab dimensions shown are for guideline

purposes only.

8. Concrete to be 28 day compressive strength to 4000 PSI.

9. NO. 4 rebar ( 1/2") grade 60 steel per ASTM A615: connected with tie wire.

10. Rebar to be 2 1/2" from edge of concrete.

11. Rebar spacing 12" grid. 4" spacing around access openings.

12. All pipe penetrations to be sleeved or have slip connections.

BELOW GRADE INSTALLATION INSTRUCTIONS

EXCAVATION

Install unit(s) as close as possible to fixtures being serviced.

1.

Width and length of excavation shall be minimum 12" greater

2.

than the tank on all sides.

Depth of excavation shall be 6" deeper than tank bottom.

3.

Set the tank level in well-packed crushed aggregate material

4.

approximately 3/4" size rock, or sand, with no fines.

Anchor kit is recommended for installations in high water table conditions to

5.

prevent float out. To be determined by specifying engineer. If necessary,

order optional "Anchor Kit" (see detail right).

INTERIOR OR EXTERIOR BELOW GRADE INSTALLATION INSTRUCTIONS

Stainless steel

anchor strap

Stainless steel

Anchor plate

Stainless hardware

ANCHOR KIT INSTALLATION DETAIL

Anchor Kit Installation Steps

Slide "Anchor Hook" over tie down point on end wall and

1.

bolt to Anchor Strap.

Bolt "Anchor Strap" to "Anchor Plate" using provided hardware

2.

Hold down force achieved by backfill weight acting on Anchor Plate.

3.

Anchor Plate may be bolted to concrete slab, if required, by using

4.

holes provided in Anchor Plate.

Stainless steel

anchor hook

ECO:

02/18/19

MJ

REV:

DATE:

DWG BY:

DESCRIPTION:

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF

STRIEM, LLC.

ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF

STRIEM, LLC.

IS

PROHIBITED.

SHEET NUMBER:

3 of 4

NOTES:

Striem Sand Incterceptor tanks are not to be installed in any other manner except as shown. Consult local

codes for separate trapping requirements, cleanout locations and additional installation instructions.

SAND INTERCEPTOR INSTALLATION,

OPERATION AND MAINTENANCE GUIDE