24

BA_170-22D_A14_180704_en

5

5.1

Operating the machine

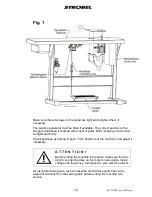

It is recommended to equip the machine with a pneumatic lifting device to

facilitate machine handling (please see “

General

8.2 Pneumatic lifting”).

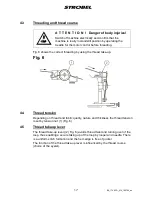

A T T E N T I O N !

Please observe the sewing area carefully during sewing.

Otherwise danger of finger bruises and needle

throughstitches.

5.2

Connect the compressed-air conditioner to the compressed air supplier

(10 bar) or to the compressor and set it to 6 bar. Switch on main switch on the

right hand side under the table top, control lamp in the "OFF" switch lights red.

On machines with pneumatic lifting now the material support arm is open, the

machine is ready to sew.

Switching on

5.3

a)

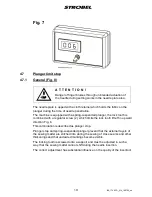

Treadle lifting

Placing and removing the fabric - sewing process

By pressing the left hand treadle the cloth support arm is lifted.

Place material under the needle plate and leave the left hand treadle. The

machine starts sewing by operating the right hand treadle.

The machine runs at maximum speed when the right hand treadle is

completely pressed down (see “4.9 Motor”).

b)

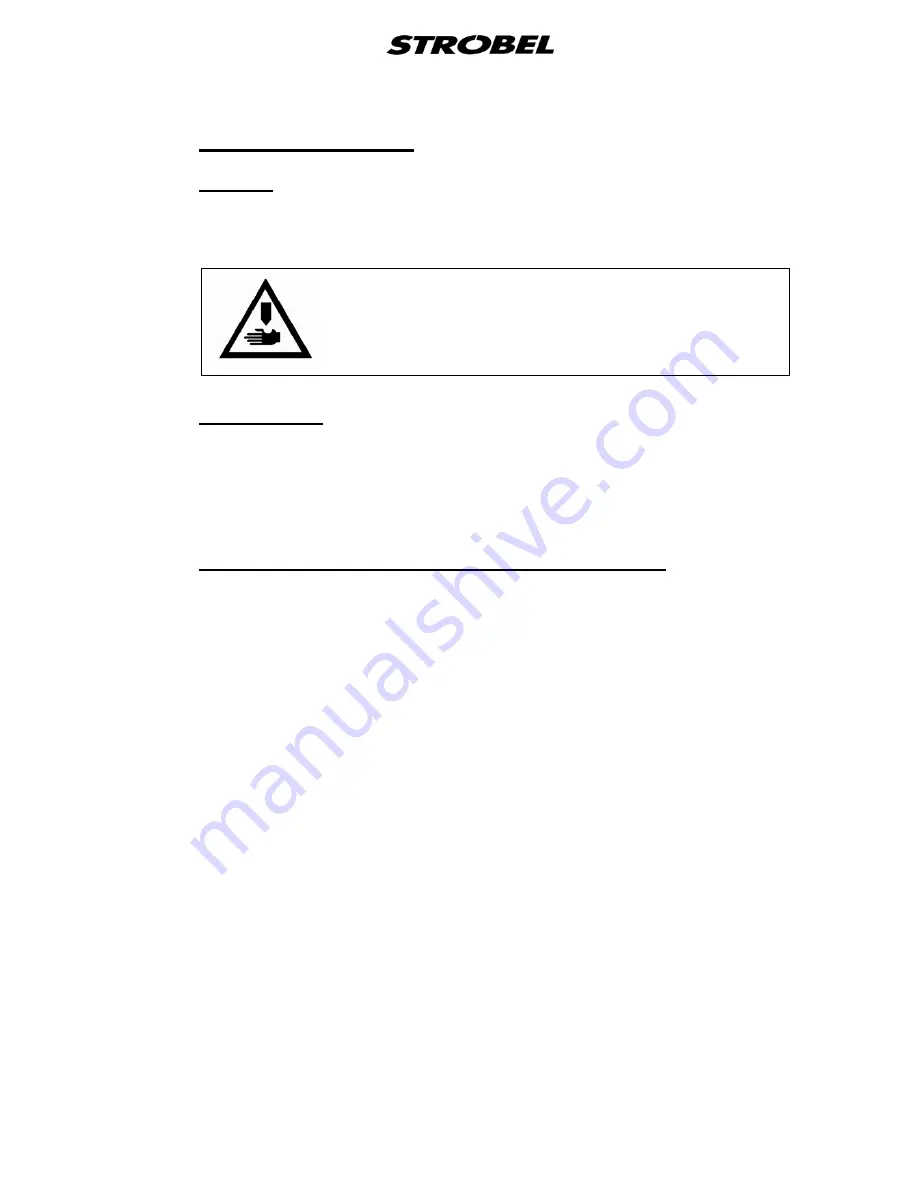

Pneumatic lifting (optional extra)

Fig. 5 shows the treadle's switching functions when the machine is

equipped with pneumatic lifting. Place the fabric under the needle plate

while the cloth support arm is lifted and close the arm by slightly pressing

the treadle (+1).

The machine is now ready to sew.

If the fabric is not placed correctly, the cloth support arm can be lifted

again by heeling the treadle back into its initial position. At the end of the

sewing process the thread trimmer (optional extra) is operated and the

cloth support arm is lifted by heeling the treadle (-1).

Summary of Contents for 170-22D

Page 4: ......

Page 5: ...1 BA_170 22D_A14_180704_en ...

Page 6: ...2 BA_170 22D_A14_180704_en ...

Page 29: ...25 BA_170 22D_A14_180704_en Fig 10 ...

Page 40: ......