9 Troubleshooting

9.1

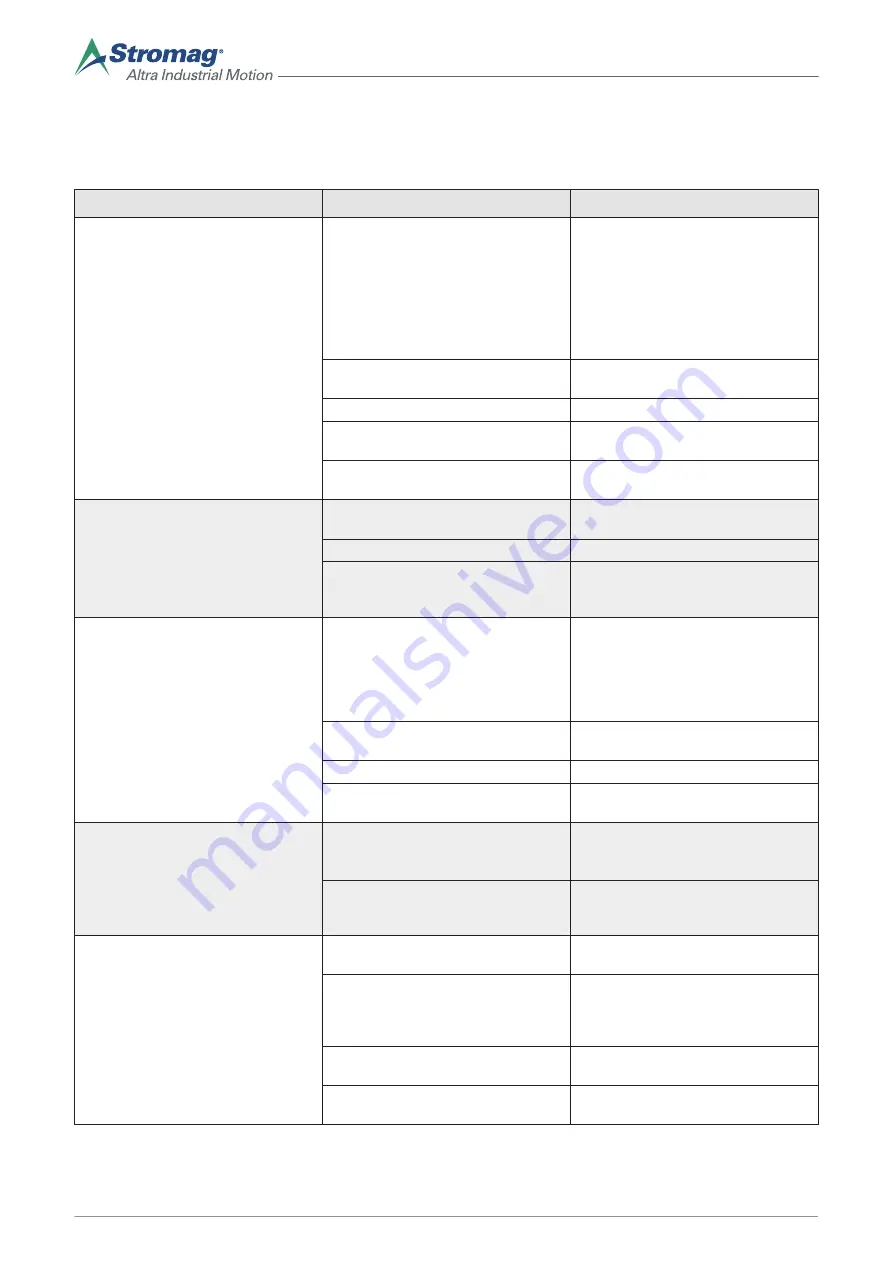

Operational issues and their solutions

Faults

Possible causes

Required measures

The clutch does not engage

The electric supply is not working prop-

erly

Check the fuse,

check the electrical supply, measure

the coil current, check that carbon

brushes or plugs are arranged correct-

ly, verify switch and relay contacts

if present, check the multiplier for fail-

ure, check brush running surfaces on

the slip ring for damage

Coil failure

Contact Stromag’s Customer Care de-

partment

Air gap is too big

Check or adjust the air gap

Magnetic coil defective

Measure the coil resistance and re-

place the coil body if necessary

Disc or toothing guides incorporated,

discs jam

Replace disc pack and/or outer body

and coil body

Clutch does not disengage

Discs jam

Replace disc pack and/or outer body

and coil body

Air gap is too small

Adjusting the air gap

Contact on the contactor is burnt

Install over-voltage protection or check

that which is already installed, replace

the contactor

The clutch slips during operation

Insufficient voltage or when voltage is

cut off temporarily

Adjust the nominal voltage (measure

clutch slip rings or plug connections),

verify contacts and over-voltage resis-

tances, check brushes - if oscillation

and significant oil content is detected

arrange two brushes per slip ring

Load torque is too high

Measure load torque, control bearing

positions

There is no longer an air gap present

Adjusting the air gap

Friction surfaces are not grease-free

when the clutch is in dry operation

Degrease the friction surfaces

Coil is burnt

Coil voltage is too high

Measure the voltage, if necessary ad-

just it correctly;

Arrange for Stromag to replace coil

Clutch was engaged without over-volt-

age protection (winding short circuit/

short circuit to earth)

Contact Stromag’s Customer Care de-

partment

Significant slip ring wear; brush wear

Circumferential speed of slip rings rela-

tively high

Arrange three brushes per slip ring

Brushes slip

Check concentric run of slip rings. If

oscillations are detected in drive, ar-

range two brushes at approx. 90° off-

set per slip ring

Dirt accumulation on slip rings during

operation

Seal slip rings, eliminate contamination

cause

Inadequate surface pressure of brush-

es

Correct brush pressure

42

Mounting instructions Electromagnetic multi-disc clutch EKE/EKB, EDE/EDB • No. 500-00000 C • 10/2017

Summary of Contents for EDB Series

Page 2: ......

Page 6: ...VI Montageanleitung Elektromagnet Lamellenkupplung EKE EKB EDE EDB Nr 500 00000 C 10 2017 ...

Page 54: ......