BULB ALIGNMENT AND OPERATION

CLOSE AND LOCK the lamphouse access doors. Turn on the exhaust system. Close the

douser. Energize the distribution panel by turning the

MASTER

circuit breaker to the

ON

position (light ON).

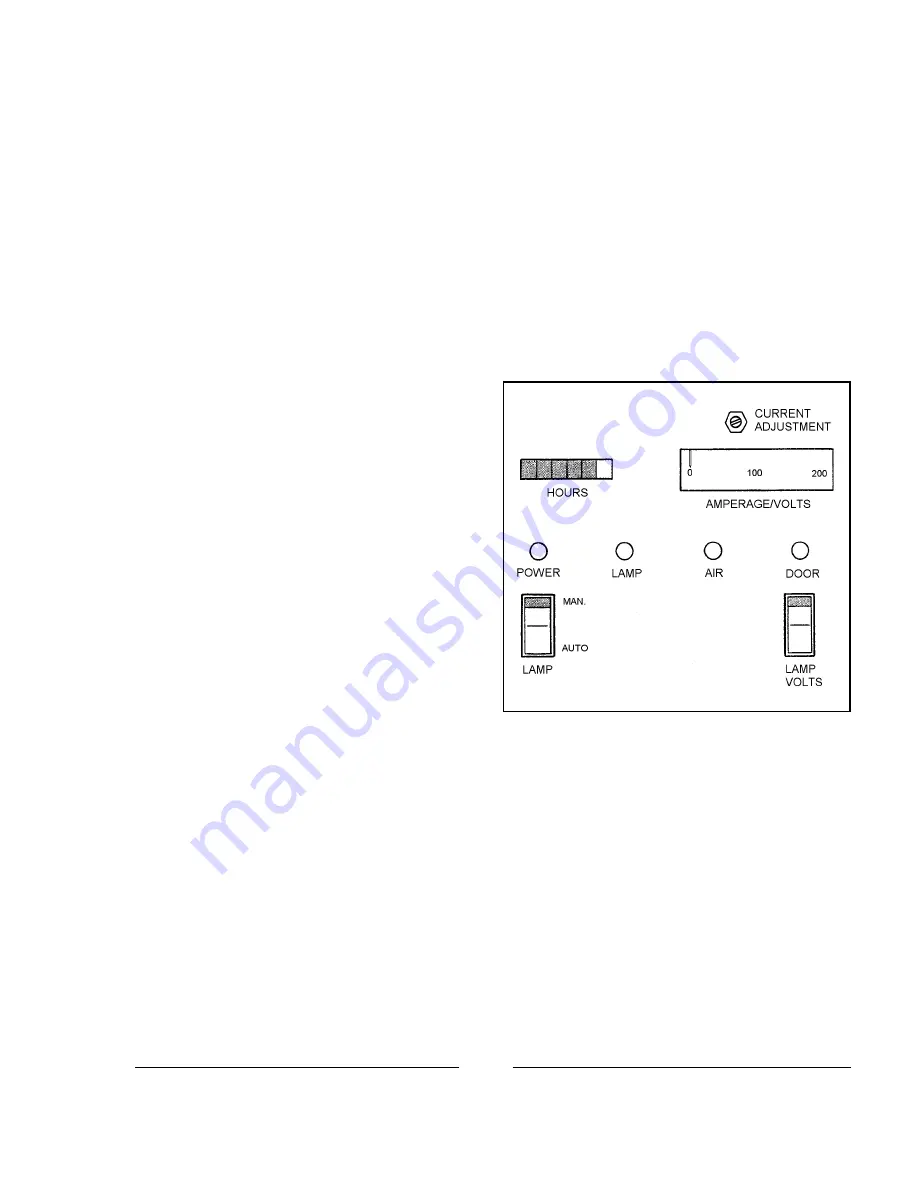

When the LAMP circuit breaker is closed, the indicator lights for

“POWER,” “AIR,”

and

“DOOR”

will light.

IN NORMAL MODE, the

LAMP “ON”

indicator and the xenon bulb will not light until cued

by the automation controller. For test purposes, select

“MAN.”

mode (upper position). The

LAMP “ON”

indicator will light, and the xenon bulb will ignite.

CHECK THE BULB CURRENT at the am-

meter. If not operating within specified range, adjust

the xenon power supply to obtain the correct output.

The operating current range is noted in the xenon bulb

warranty information. Do not exceed the maximum

current specified by the bulb manufacturer.

A NEW XENON BULB is normally operated

at or near its nominal current. As the bulb ages, the

quartz envelope normally will darken. The current can

then be gradually increased to compensate for the light

loss caused by the darkening envelope.

PRESS THE

“LAMP VOLTS”

switch to

change the ammeter to display arc voltage. To deter-

mine exact wattage, multiply volts time amperes.

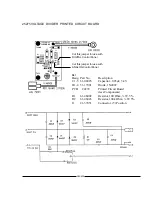

THE ANALOG ELAPSED TIME METER (as illustrated) will record the hours of bulb

operation. The meter runs only when the xenon bulb is operating.

THE OPTIONAL DIGITAL INSTRUMENT PANEL continuously displays the bulb current

(A), arc voltage (V), wattage (W), and elapsed hours. Elapsed hours are displayed as Bulb Hours (BLB) and

Total Hours (HR). Bulb hours can be re-set to zero after replacing the xenon bulb. Prior to bulb ignition,

electrical data is displayed as zeros, but the backlighting of the display screen indicates that power is ON.

ADJUSTMENT CONTROLS are provided to correctly position and focus the xenon bulb.

Bulb adjustment controls, located on the distribution panel immediately above the

MASTER

circuit breaker,

position the bulb inside the reflector on the horizontal and vertical planes. The focus control knob, located

adjacent to the douser handle, moves the bulb in and out of the reflector on the horizontal plane.

REMOVE THE PROJECTION LENS, turn on the projector motor, and open the douser. A

black spot should appear in the center of the screen. Adjust, tilt, or reposition the console as required to center

the spot on the screen.

X90/013

Summary of Contents for X-90

Page 2: ......

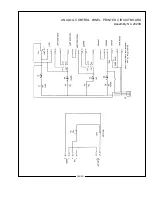

Page 21: ...X 90 LAMPHOUSE SCHEMATIC Analog Controls X90 019 ...

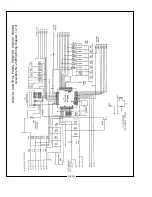

Page 23: ...ANALOG CONTROL PANEL PRINTED CIRCUIT BOARD Assembly No 23239 X90 021 ...

Page 24: ...X90 022 DIGITAL CONTROL PANEL PRINTED CIRCUIT BOARD Assembly No 23976 Wiring Diagram 1 of 3 ...

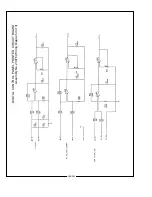

Page 25: ...X90 023 DIGITAL CONTROL PANEL PRINTED CIRCUIT BOARD Assembly No 23976 Wiring Diagram 2 of 3 ...

Page 26: ...X90 024 DIGITAL CONTROL PANEL PRINTED CIRCUIT BOARD Assembly No 23976 Wiring Diagram 3 of 3 ...

Page 43: ......

Page 44: ......