INSTALLATION

(continued)

OBSERVING ALL SAFETY PROCEDURES, install a xenon bulb of the desired

wattage into the lamphouse. Check the bulb manufacturers documentation to determine the recom-

mended current range of the bulb. A new bulb is normally first operated at nominal current, which

is around 85% of the maximum level. DO NOT, at any time, exceed the maximum current level

specified by the bulb manufacturer.

IGNITE THE XENON BULB and check the current as indicated on the lamphouse

ammeter. Allow (30) seconds for the current to stabilize and provide an accurate reading. If the

current is not within the desired range, extinguish the bulb. It will be necessary to increase or de-

crease the DC output.

WARNING

Turn off ALL primary AC power before making any

adjustments or performing service procedures. Allow

several minutes for the capacitors to drain stored en-

ergy. The power supply normally operates warm to hot;

allow the unit to cool to room temperature.

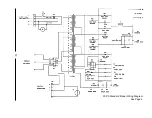

OUTPUT CURRENT ADJUSTMENT

Fine adjustment

of the DC current is made to the

NUMBERED

taps found on the upper three

terminal blocks (TB4, TB5, TB6). Fine taps are numbered 1-2-3-4, with 1 providing the

lowest

output, increasing to 4, yielding the

highest

output. A fine tap adjustment raises or lowers the

current approximately four amperes. The three fine tap terminal blocks are interconnected by means

of a three-lead jumper wire assembly attached to like-numbered terminals.

To

increase

the DC output, move the jumper wire assembly to tap the next (3)

higher

numbered

terminals, for example, move from terminals 2 to terminals 3. ALL TAPS MUST BE ON THE

SAME NUMBERED POSITION (1-1-1, 2-2-2, 3-3-3, or 4-4-4). If the DC output is still too low

when terminals 4 are interconnected, see the following instructions for adjusting

coarse

taps.

To

decrease

the DC output, move the jumper wire assembly to tap the next (3)

lower

numbered

terminals, for example, move from terminals 3 to terminals 2. ALL TAPS MUST BE ON THE

SAME NUMBERED POSITION (1-1-1, 2-2-2, 3-3-3, or 4-4-4). If the DC output is still too high

when terminals 1 are interconnected, see the following instructions for adjusting

coarse

taps.

Coarse adjustment

of the DC current is made to the

LETTERED

taps found on the lower three

terminal blocks (TB1, TB2, TB3). Coarse taps are lettered W-X-Y-Z, with W providing the

lowest

output, increasing to Z at the

highest

output. The coarse tap terminals connect to contactor termi-

nals T1, T2, and T3. The (3) contactor leads must connect to the same lettered step (W-W-W, etc.).

A coarse tap adjustment raises or lowers the current approximately twelve amperes.

2

Summary of Contents for XENON FXPS

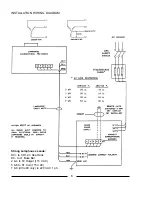

Page 12: ...FXPS Standard Model Wiring Diagram See Page 4 10 ...

Page 13: ...FXPS Model LB Wiring Diagram See Page 5 11 ...

Page 18: ......