INSTALLATION

(continued)

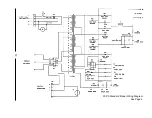

To

increase

the coarse DC output, move each of the contactor leads to tap the next

higher

lettered

terminals, for example, move from terminals W to terminals X. ALL TAPS MUST BE ON

THE SAME LETTERED POSITION (W-W-W, X-X-X, Y-Y-Y, or Z-Z-Z). Place the fine tap

jumper on 1-1-1. Ignite the lamp, check the output, and increase the fine tap setting as required.

To

decrease

the coarse DC output, move each of the contactor leads to tap the next

lower

lettered

terminals, for example, move from terminals Y to terminals X. ALL TAPS MUST BE ON

THE SAME LETTERED POSITION (W-W-W, X-X-X, Y-Y-Y, or Z-Z-Z). Place the fine tap

jumper on 1-1-1. Ignite the lamp, check the output, and increase the fine tap setting as required.

INSPECT TAP CONNECTIONS to verify that the terminal is clamping the copper

conductor, not the insulation. Make certain all terminal clamping screws are tight.

WHENEVER MAKING A COARSE ADJUSTMENT, again check the lamphouse

ammeter and make certain the current is within the desired range. A fine tap re-adjustment is fre-

quently required after changing coarse taps.

AFTER PROLONGED OPERATION, the light output of the xenon bulb will decrease.

This is a normal factor of bulb aging, and can be compensated by raising the DC output of the xenon

power supply. If the bulb was first operated at nominal current, the power supply output can

gradually be increased to, but not in excess of, he maximum current specified by the bulb manufac-

turer. Increase the current as instructed above. Decrease the power supply output to its former

nominal current level upon the installation of a new replacement bulb.

MAINTENANCE

VERY LITTLE MAINTENANCE is required to keep this power supply in good

operating condition. Like most booth equipment, regularly scheduled cleaning is most important.

WARNING

Turn off ALL primary AC power before making any adjustments or

performing service procedures. Allow several minutes for the

capacitors to drain stored energy. Allow the power supply to cool

to room temperature.

1. Remove all accumulated dust and dirt from the rectifier. Vacuum the heat sinks. Make certain all

air inlets and outlets are unobstructed.

2. Regularly check all electrical connections for tightness. Clean, retighten, or replace any discolored

connections or terminals.

3. Every three months, apply a drop or two of SAE 20-weight oil to the squirrelcage blower motor

bearings (on units so equipped). Muffin fans require no lubrication.

3

Summary of Contents for XENON FXPS

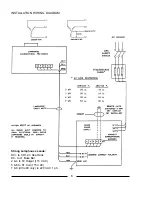

Page 12: ...FXPS Standard Model Wiring Diagram See Page 4 10 ...

Page 13: ...FXPS Model LB Wiring Diagram See Page 5 11 ...

Page 18: ......