Pg. 5

SM-RAZOR-ART1-M Installation Manual

www.snapav.com Support: 866.838.5052

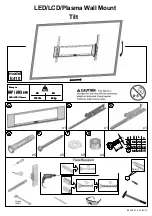

Step 3. Install the Mounting Bracket on the Wall

A. For Mounting on a Stud Wall

1. Locate a stud to mount the bracket on. Mark the center line

of the stud on the wall. The use of a stud finder is highly

recommended.

2. Using a level for guidance, hold the bracket on the wall and

mark the mounting holes that will be used. The holes will be

centered on the height mark from Step 2. Be sure that the

arrows on the bracket face up toward the ceiling.

3. Pre-drill the holes to a depth of 3 1/2” using a 1/4” drill bit. Be

sure to drill into the center of the stud.

4. Insert the lag screws (R) through the washers (S) and the

wall plate, and thread them into the holes in the wall. Tighten

the bolts so the bracket is firmly attached to the wall.

Warning:

Over-tightening can damage the bolts, greatly reducing

their holding strength. Do not over-tighten!

Screw Holes:

-

ø

1/4"

-Depth 3 1/2"

(R) x2

(S) x2

Wall Plate

Screw Height

Mark (From

Step 2)

Figure 4.

Single Stud Bracket

Important!

If the optional Dual Stud Mounting Bracket (SM-RAZOR-ART1-BKT-20) is being used to hang the mount

on the wall, refer to the SM-RAZOR-ART1-BKT-20 manual (included with the bracket) to complete Step 3.

Summary of Contents for SM-RAZOR-ART1-M

Page 12: ... 2013 STRONG 130820 1600 ...