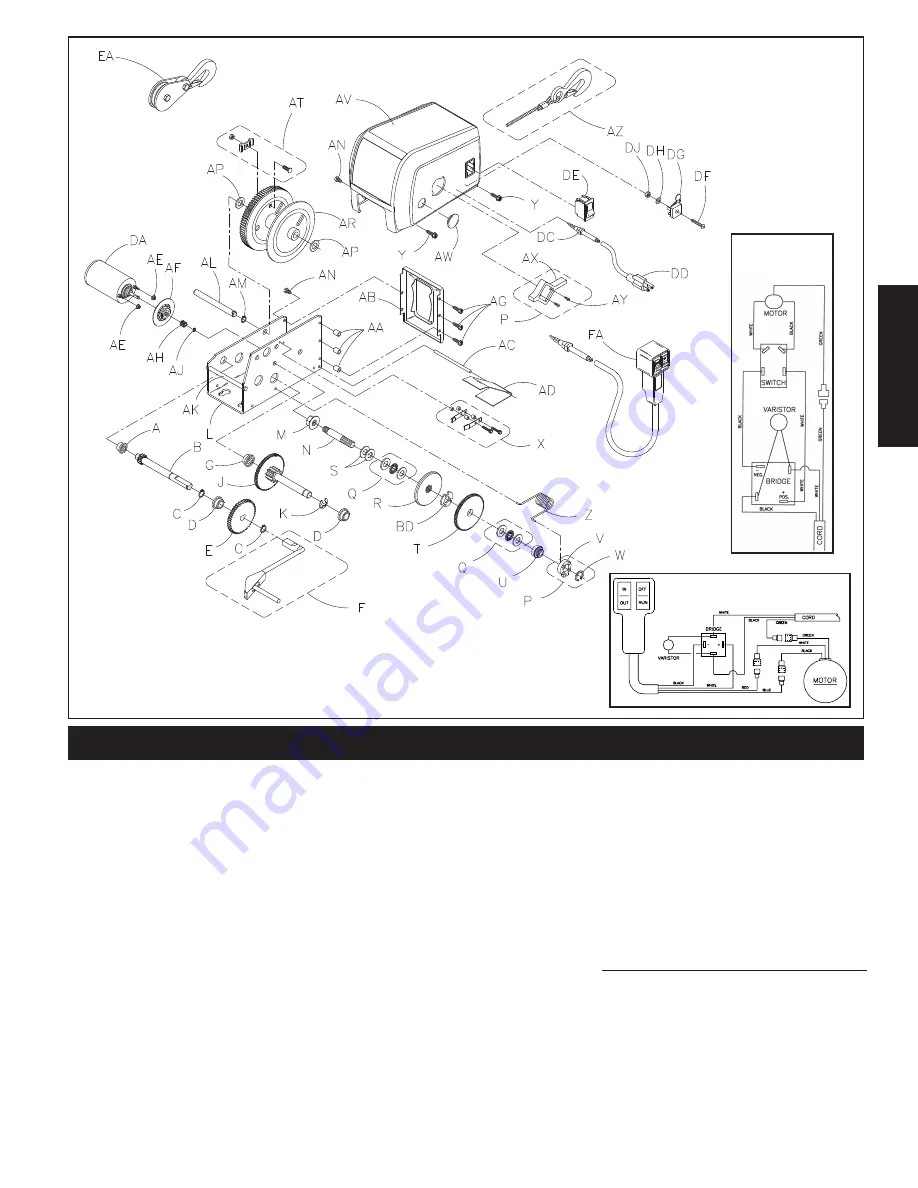

SA9000AC and SA12000AC PARTS LIST

Ref. Part

Number

A

Bearing Housing Assy.

304314

B

Primary Drive Shaft Assy.

304304

C

Retaining Ring (2)

205191

D

Bushing (2)

204012

E

56T Gear

204703

F

Aux. Handle Assy.

5703079

G

Drive Shaft Bushing

304313

Housing Assy.

J

Interm. Drive Shaft Assy.

304814

K

“E” Ring

205116

L

Base

404921

M

Nut, 7/16-20 Locknut

205192

N

Clutch Stud

404517

P

Clutch Handle Replacement Kit 5703178

(Includes Items V, W, AX & AY)

Q

Thrust Bearing Replacement Kit 5703194

(Includes Item W, O-Ring)

R

Clutch Gear Assy

306100

S

Washer (2)

204360

T

84T Gear Assy

306101

U

Clutch Handle Nut

404518

V

Clutch Spring Keeper

204721

W

“O”-Ring

204770

X

Brake Spring Replacement Kit

5703160

Y

Screw, 1/4-20x1" (2)

205190

Z

Clutch Spring

204711

AA

Spacer (3)

404513

AB

Front Plate

404511

Ref. Part

Number

AC

Level Wind Pin

404516

AD

Level Wind

204709

AE

Nut, 10-32 Locknut (2)

205193

AF

Brake Disc Assy.

304422

AG

Screw, 1/4-20x7/8 (3)

205242

AH

12T Pinion Gear

404522

AJ

“E” Ring

205135

AK

Base Spacer

404510

AL

Reel Shaft

404514

AM Retaining Ring

204468

AN

Screw, 1/4x20x1/2" (4)

205189

AP

Washer (2)

205109

AR

Reel Assy.

304815

AT

Rope Clamp Kit

5243506

AV

Cover-SA9000/12000AC

204747

AV

Cover-SA9015AC/12015AC

204630

AV

Cover-(CSA) SA9000/12000

404942

AV

Cover-(CSA) SA9015/12015

404593

AW Cover Plug

204713

AX

Clutch Handle

204712

AY

Screw – #4x1/2

205196

AZ

Cable & Hook

5240478

(7/32x25') (SA9000AC)

AZ

Cable & Hook

5240452

(7/32x50') (SA12000AC)

BD

Finger Spring Washer

205200

BE

Top Decal (Not Shown)

204737

BG

DL Decal (Not Shown)

204729

BH

Clutch Decal (Not Shown)

204731

MOTOR PARTS

DA

Motor Assy

304921

DC

Strain Relief Bushing

206670

DD

Electrical Cord

205038

DE

Switch

204419

DF

Screw – 8-32x1"

205180

DG

Bridge Assy

304426

DH

Washer

205194

DJ

Nut – 8-32

205195

PULLEY BLOCK

EA

Pulley Block & Hook (Complete) 5240270

REMOTE SWITCH

FA

Switch Assy

5240890

FA

IN/OUT Rocker Switch only

204491

FA

OFF/RUN Rocker Switch only

204490

E

N

G

L

I

S

H

7

WIRING DIAGRAM

SA9000AC/12000AC

To order replacement parts contact:

Dutton-Lainson Company

www.dlco.com

Tel: 800-569-6577 • Fax: 402-460-4612

e-mail: DLsales@dutton-lainson.com

In Europe Contact:

Bainbridge International Ltd.

8 Flanders Park

Hedge End

Southampton

Hampshire, SO30 2FZ UK

Tel: +44 (0) 1489-776050

Fax: +44 (0) 1489-776055

www.bainbridgemarine.co.uk

WIRING DIAGRAM

SA9015AC/12015AC