GEARED KEY

: To open and close

the chuck. The key is supported in

two places, for easy action and long

life.

Your key will come disassembled.

Insert the cross bar into the hole in

the key and put the O-rings (which

are packed in a small plastic bag) on

each end to secure it in place.

5

BODY

: The

main part of

the chuck. It

holds all

other parts

as an

assembly.

PROFILED TOP

JAWS

: The No. 2

Jaws which are

attached to the

base jaws and

will hold the

wood to be turned.

BASE JAWS

: The

carriers to which the

top jaws are attached

with two countersunk

screws. They are

numbered 1 through

4 on the side.

4

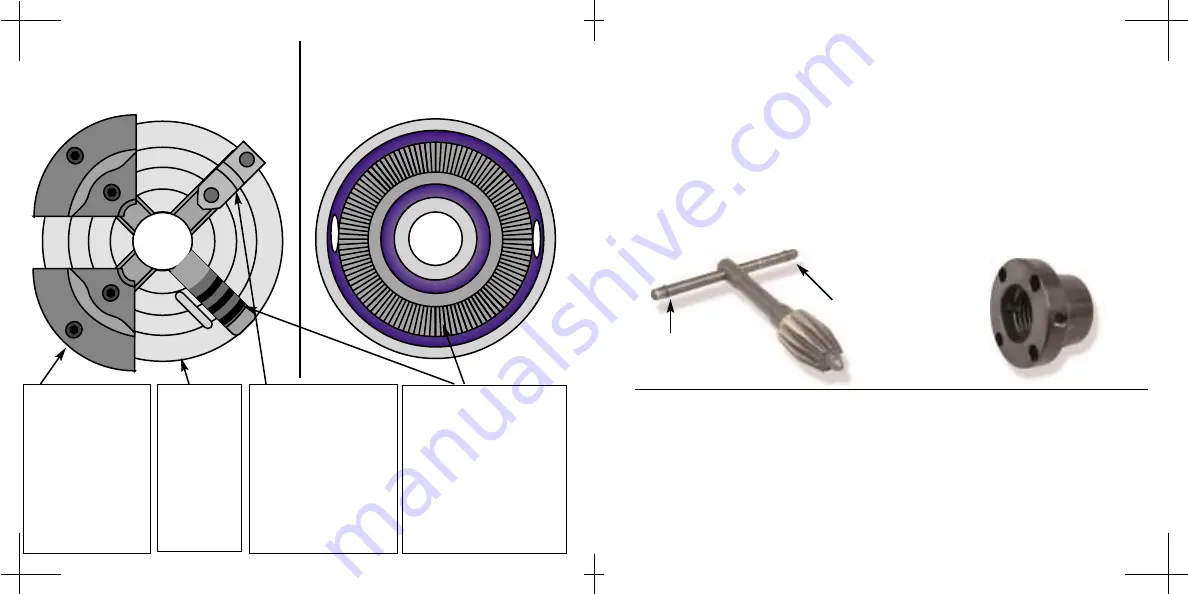

YOUR CHUCK DESCRIPTION

THE SCROLL

: The

cylindrical part which

has a gear cut on one

side and a flat surface

thread on the opposite

side which moves the

base jaws in and out in

unison.

TAPERLOCK ADAPTOR:

Made with various threaded sizes

so it can be made to fit any lathe

spindle. If you change lathes, all

you need to do is buy a new adap-

tor, not a whole new chuck. The

taperlock design eliminates the pos-

sibility of the adaptor loosening or

separating from the chuck body in

normal use or when reversing the

lathe.

NOT SEEN:

SNAP RING

: The clip which holds the scroll in place. Snap ring pliers are

required to remove the scroll if necessary (Anderton #6 external snap ring

pliers)

4 MM T-HANDLE HEX KEY

: Used to install or remove the adaptor

and/or the Top Jaws.

Back view of STRONGHOLD chuck

with the adaptor removed.

YOUR CHUCK DESCRIPTION

ON

E WAY

1

CANADA

O-Ring (#009)

Cross Bar

Top view of STRONGHOLD chuck. The

chuck is shown partially disassembled to

help illustrate all of its components.