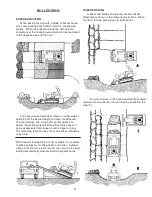

Drive your Crawler through a “clean” area to

work out debris that may have lodged between

Track Sprocket teeth or in the Track’s Chain Links.

Park your Crawler on a firm level surface, shut off

engine and dismount.

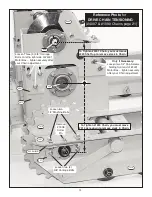

On the side of the Track you are going to

tension, remove its respective #1220 Spring

Guard...save Bolts & Nuts for reassembly.

Remove the 1/2” Nut at the extreme end of

each #1030 Rod.

If your tracks have a lot of slack in them or if

you have replaced a broken #1030 Rod, follow

this procedure:

With

a

wrench

or

pneumatic

tools

(recommended); rotate each #1030 Rod so that

its respective #235 Washer is drawn

forward

(or

released

rearward

)

thereby

adjusting

its

respective #234 Spring (black) or #233 Spring

(yellow).

. Work back and forth tightening each Spring 1/4”

at a time.

(Follow the guidelines for tightening the

springs in the Track Replacement Section above).

You want to take out the slack in the tracks, don’t

over tighten. Make sure the front axle is square

and that you are satisfied with the track tension.

At this time remount and safely restart your

Crawler. Drive it approximately 25 feet forward

and then go in reverse back to your starting point.

Shut off the engine and dismount.

Check the

overall length of your #233 & #234 Springs for any

changes in length. Readjust if necessary. When

satisfied, secure each 1/2” Nut (on end of each

#1030 Rod) with another 1/2” Nut...fully tighten.

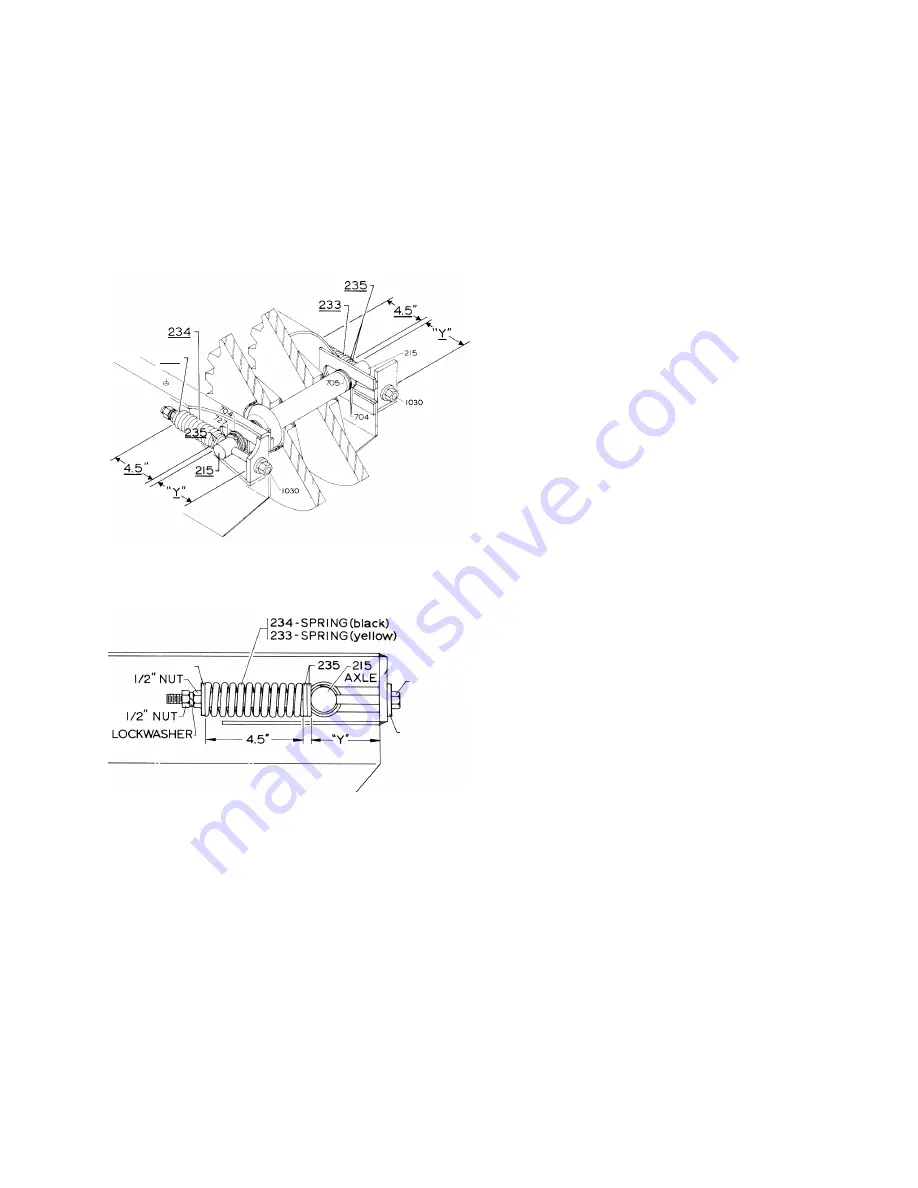

NOTE

: To achieve ideal Track alignment, the

“Y” distance (the distance from the rear face of the

#215 Front Axle forward to the

rear face

of the

frame block) should be equal on each end of the

#215 Axle you are adjusting.

To accomplish this, loosen the 1/2” Nut on the

end of the #1030 Rod holding the #233 Spring

(yellow) and “fine tune” the overall length of the

#233 Spring using the procedure described

above.

When

equal

“Y”

distances

have

been

achieved, replace and tighten the 1/2” Nut on

extreme end of #1030 Rod holding the #233

Spring (yellow).

Using original Spin Lock Bolts and Nuts,

replace the #1220 Spring Guard removed

above...tighten.

NOTE:

To get the most life out of your tracks;.

you can take two track pads out of your tracks

after a period of time where they have stretched to

the max. Make sure you have tightened your

springs as much as possible and that you have no

more room in the slot where the #215 front axle

sits. To do this, follow the steps in the Track

Removal section of this manual and then put each

track on end and grind down each pin head till it

sits flush with the outer chain link. Using a vise-

grip; secure it into a 1/4 punch or long 1/4 inch bolt

and lock vise-grip into place. Use a lubricant, like

WD40 to ease the pin out.

With a hammer,

carefully pound the pin through without hitting

your hand or damaging the mating outer link and

secure with new pins and cotter pins purchased

from the factory.

NOTE: You need to match up

an inner track link and an outer track link to

make a connection to each other.

Contact the factory with any questions!

TRACK SPROCKET &

TRACK IDLER LUBRICATION

Lubrication

of

the

#1218

Idlers

is

accomplished by greasing through #2061 grease

Fittings.

The grease Fittings are “submerged

mounted” in the outside ends of all eight of the

27

235

235

1030

235