BM40

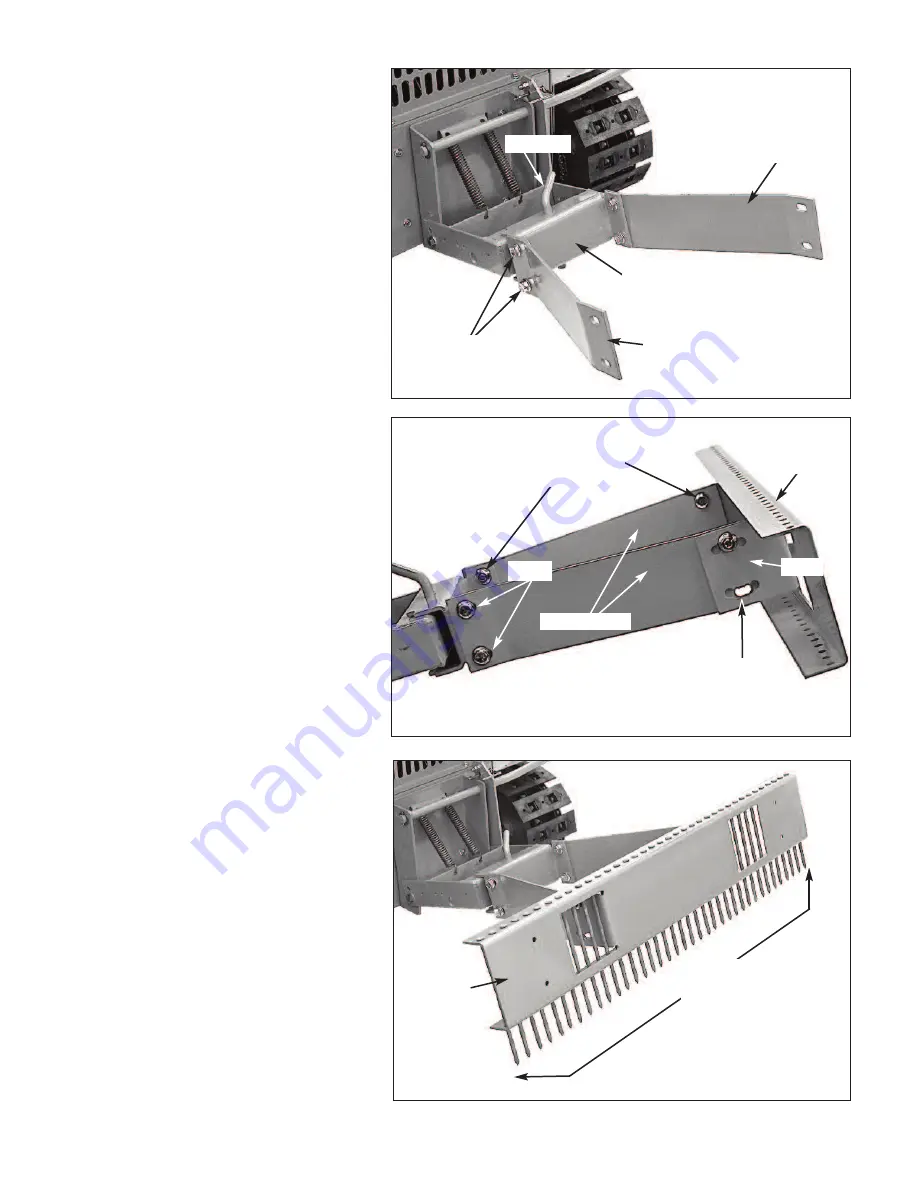

STEP 3.

Mount and secure with

AN Bolts & MM Nuts a #2261 Arm on

outside face

of each ear of #2260

Yoke... leave Nuts loose.

STEP 4.

Slip each “tab” of

#2262 Channel

around

the mating

out-

side face

of each #2261 Arm. On each

side, align

short slot

of the #2261 Arms

with mating

circular slot

on “tabs” of

#2262 Channel.

From outside, insert #AN Bolts

into each of the eight (8) aligned pairs

of 1/2” slots... secure inside with #MM

Nuts.

STEP 5.

Square your assembly

so that it’s”top edges” are basically all in

the same “plane”... then tighten all eight

(8) #MM Nuts.

STEP 6.

Insert forty (40) #2264

Log Spikes into holes provided in #2262

Channel... use Photo at right as your

guide.

126 Pin

“tab”

AN Bolt &

MM Nut

AN Bolts &

MM Nuts

2262

Channel

“gap”

2261 Arms

2261 Arm

2261 Arm

2260

Yoke

2264

Log

Spikes

(40)

2262

Channel

Mating 1/2” slots

on

common

center