11

STARTUP, CONTINUED - OPERATION AND SHUTDOWN

(AUTHORIZED PERSONNEL ONLY!)

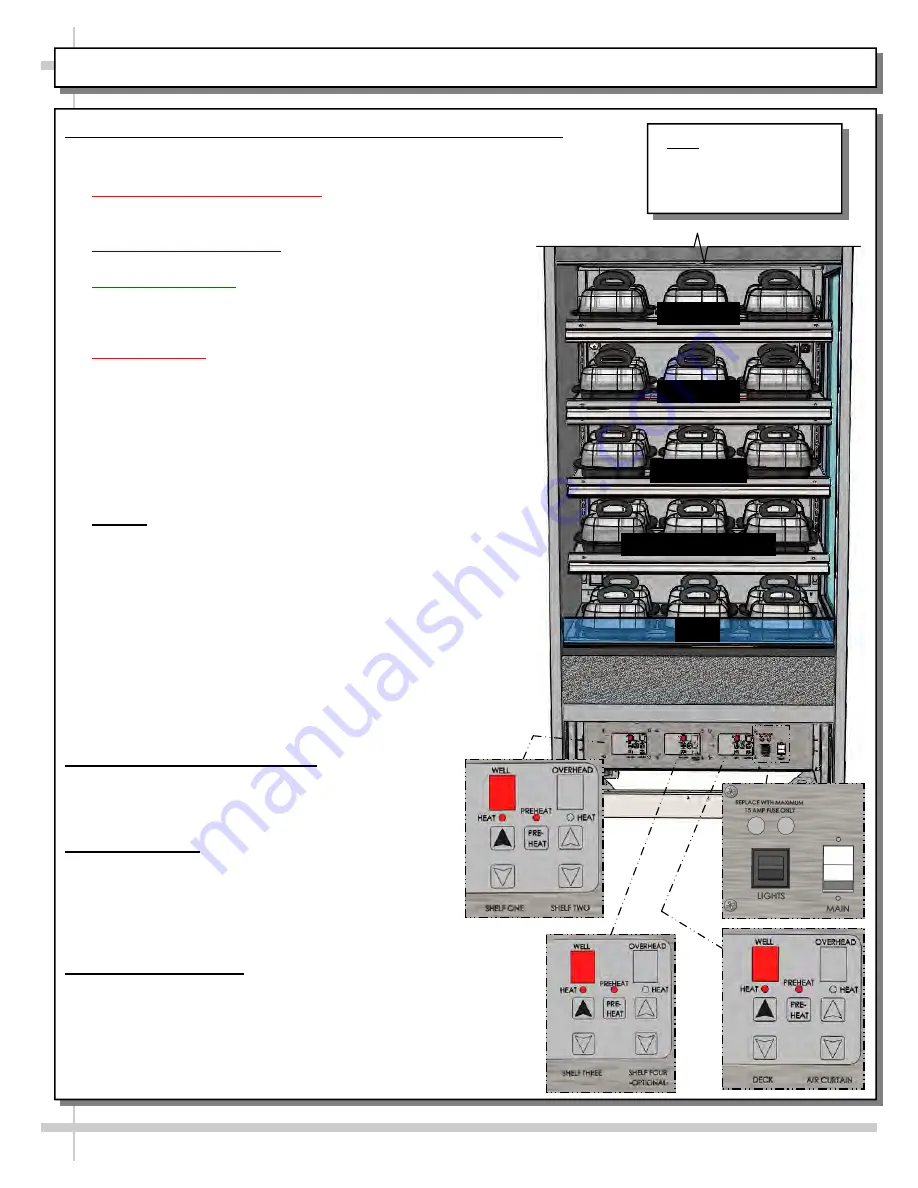

1. Merchandiser Daily Start-Up (For Authorized Personnel Only)

Lift up hinged door at case front. Both switches should be in off position.

Turn main power switch / lamp switch on.

Inoperative Dashboard Notations: Markings of “Well,” “Overhead” and

“Pre-Heat” may on faceplates. These fuctions are NOT used on these

Note: Model B3632H Is

Shown. General Layout Is

Applicable To All Models

Represented In Manual.

models and are to be disregarded.

Ceramic Metal Halide Note: Lamps may take up to 15

minutes to fully illuminate.

Heat Controller Note: Heat is controllable by the “up” and

“down” arrows on faceplates. Heat settings have a maximum

setting of “9” and a minimum setting of “1”. A setting of “0”

turns heat OFF. Default factory settings for user are “5”.

Cautionary Note: Deck, shelving and overhead lights are hot!

Do not touch unless dials have been turned off & area is cool!

Heater controls to shelves and deck are on control panel.

Heat is controllable by the pressing the “up” and “down”

arrows on faceplate. The red “HEAT” light will come on

when shelves (or deck) are warming.

Allow 15-20 minutes for temperature to reach desired

temperature before placing product on shelves/deck.

Adjust controller until desired product temperature is reached.

Caution! Food MUST BE cooked PRIOR to being placed in

the case. Food should be heated to a temperature of

between 150 °F to 160 °F (65.6 °C - 71 °C) prior to placing in

case.

Food temperature must NOT be allowed to be below

FDA guideline of 140 °F (60 °C).

Use probe to check food temperature before placing in case.

After product is placed in case, check product temperature

(again) after one hour to verify that proper food temperatures

are maintained.

Should product temperatures be outside of range, adjust

temperature controls for that particular shelf or deck up or

down by one number.

Check food temperature again after one hour.

2. Temperature Control Settings

Temperatures of all food products are to be at

140 °F to 165 °F (60 °C to 74 °C), for decks and

shelves (including optional shelf #4).

3. Operating Tips

When restocking, place new product at back and

rotate older product to front of case.

Display product expected to sell within 4 hrs.

Clean up residue immediately.

Case will cause

spills and debris to harden to surface!

4. Shutting Down Case

Remove all product from case. Turn main power switch “OFF.”

Allow case to cool for 45 minutes before cleaning.

Shelf One

Shelf Four (Optional)

Deck

5

5

5

5 5

Shelf Two

Shelf Three

![FRIGOGLASS ICM2000 [R290] User Manual preview](http://thumbs.mh-extra.com/thumbs/frigoglass/icm2000-r290/icm2000-r290_user-manual_2338092-01.webp)

![FRIGOGLASS Retro [R290] LC User Manual preview](http://thumbs.mh-extra.com/thumbs/frigoglass/retro-r290-lc/retro-r290-lc_user-manual_2338098-001.webp)