16

CLEANING SCHEDULE

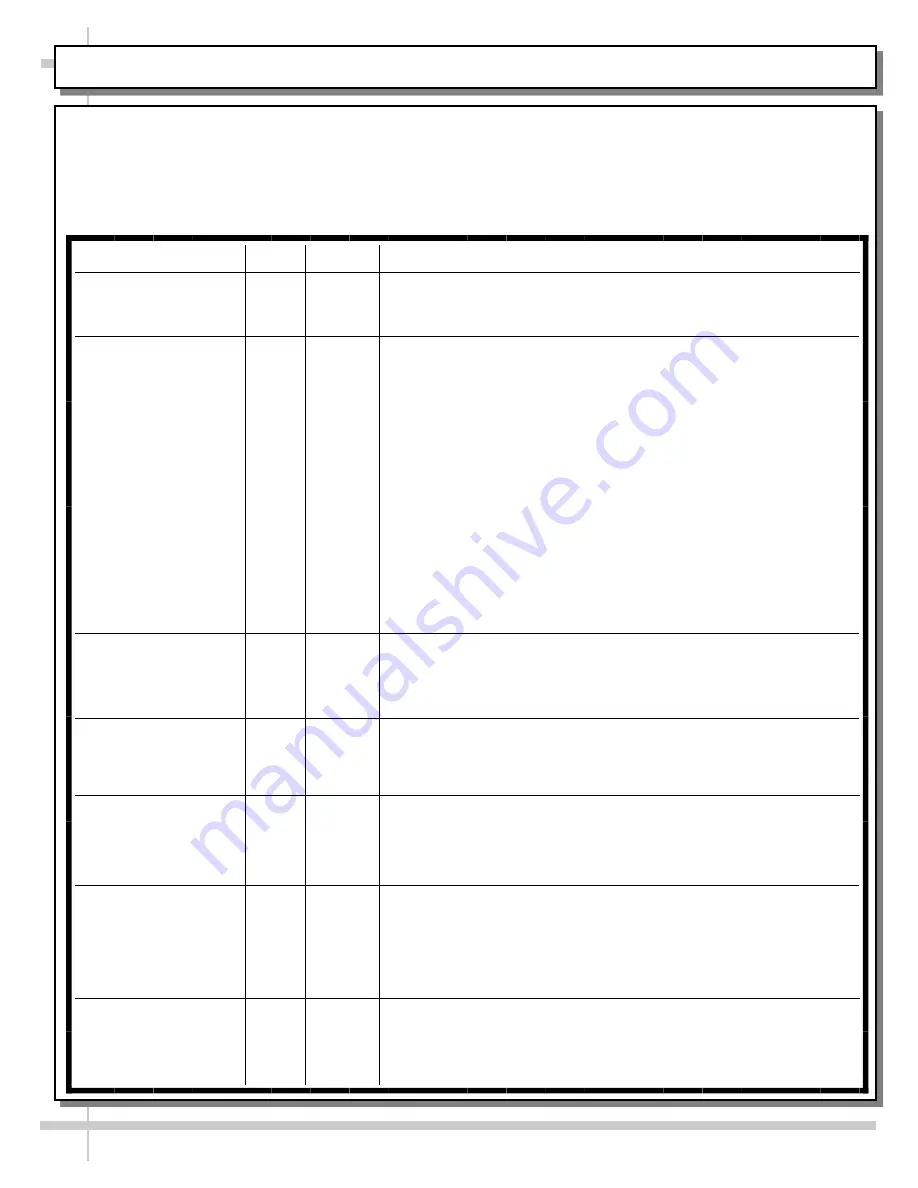

Cleaning

Daily Weekly

Task

Clean Case Exterior

X

Clean side glass, front curved glass and sliding rear doors

(glass) with a household or commercial glass cleaner.

X

Stainless Steel Rear Work Surface:

Wash with a solution of hand dishwashing liquid detergent and

water; or a solution of baking soda and water. Rinse and

polish dry with paper towel or soft cloth.

Never use scouring powders or steel wool as they will scratch

stainless steel.

Brighten by polishing with a cloth dipped in vinegar or in

ammonia; sprinkle baking soda on sponge and rub gently;

rinse. Polish dry with paper towel.

Remove streaks or heat stains from stainless steel by rubbing

with club soda.

X

Flip-down rear ledge:

Use a clean cloth with a solution of hand dishwashing liquid

detergent and hot water. Rinse and wipe dry with paper towel

or clean cloth.

Clean Case Interior

X

Clean inside surface of front curved glass and glass ends with a

household or commercial glass cleaner.

X

Remove pans (see full size and 1/3rd size pans illustrations in

MAINTENANCE FUNDAMENTALS

section of this manual)

and submerse in with warm soap and water solution.

Thoroughly dry before returning to case.

X

Pan Warmer Shield (surface under removable pans).

Caution! Turn OFF Main Power Switch. Allow wells to cool

to room temperature before cleaning.

Clean with mild soap and water solution and a soft cloth.

X

Remove rear doors and clean with a household or commercial

cleaner

Warnings:

1. DO NOT clean heated wells while hot. Flip Well Heater Switches to OFF position. Allow wells to

cool to room temperature before cleaning.

2. Lowering the front glass with items inside top cap can cause damage to case.

3. Lowering the front glass with fingers inside top cap can cause serious injury.