6

INSTALLATION: ADJOINING UNITS / CASTERS / ADJUSTING FRONT TOE-KICK

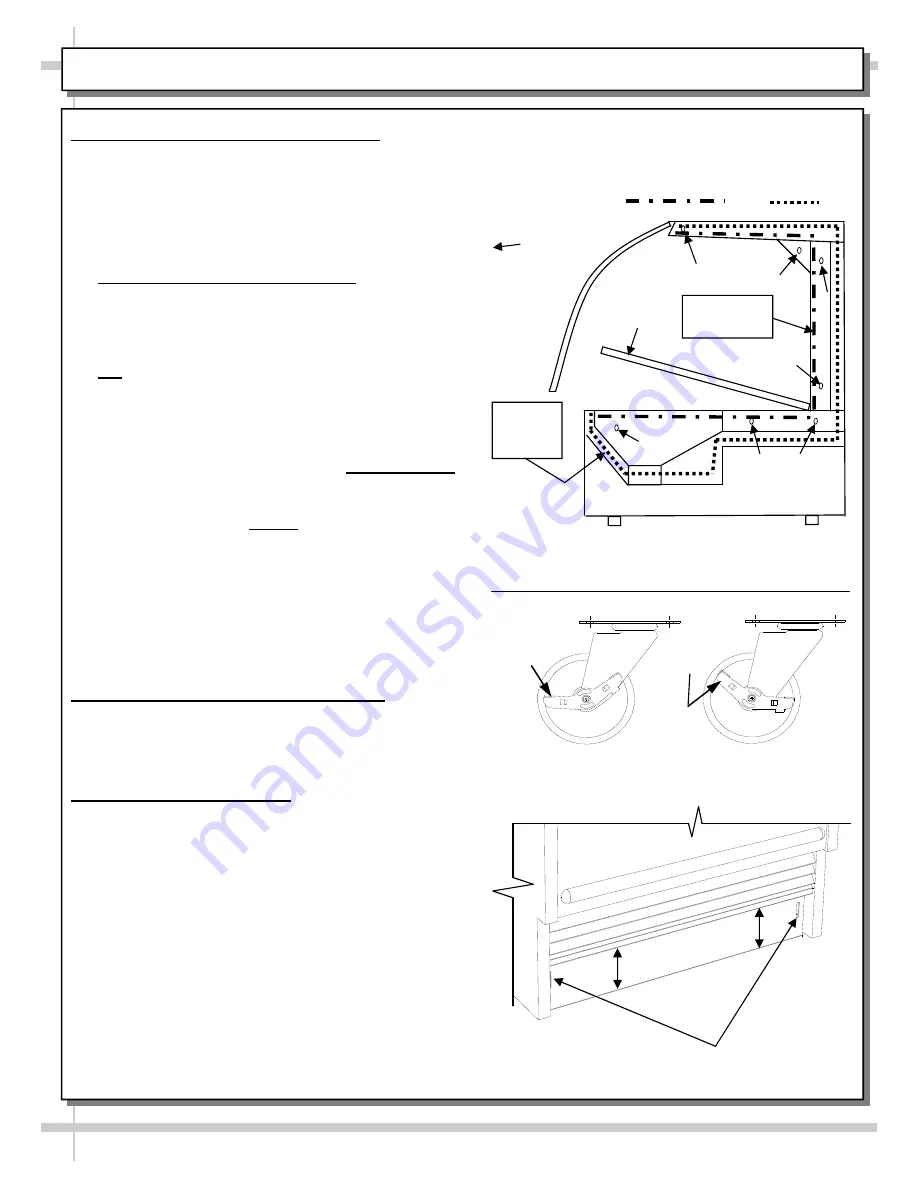

5. Bolting and Caulking Units Together

Follow these steps to assure a secure, level lineup.

A. Begin all lineups leveling from highest point of floor.

B. After the ’first’ case is level, apply industrial grade

butyl caulk on non-visible areas (at case end). Use

industrial grade silicone sealant on visible areas (at

case end).

C.

Form Two (2) Caulk/Sealant Beads: See illustration

at top-right for outline of caulk/sealant lines.

D. Line up ‘second’ case bolt-hole to bolt-hole to ‘first’

case.

E. Using SCC-supplied bolts (found in hole locations

OR in installation packet), insert bolts in bolt hole

locations (shown at top-right). You may need to

remove decking to access lower bolt holes.

F. Caution! Front of cases MUST be flush with each

other! After leveling, all cases to be same height.

G. Using SCC-supplied nuts & bolts,

lightly tighten

each of the 5 to 8 bolts in a cross-wise pattern.

Work your way around the pattern, tightening more

firmly at each pass. Do not firmly tighten one bolt

and then start on the next!

H. After the cases are bolted together, level the

‘second’ case. Repeat this process for each case

to be adjoined.

I. After all lined-up cases are level, seal all seams

with industrial grade silicone sealant.

See illustration at top-right.

6. Cases With Casters: Lock and Unlock

To lock casters, press down on lever.

To unlock casters, pull lever up.

See illustration at right.

7. Adjusting Front Toe-Kick

There is no need to adjust Front Toe-Kick on:

Model HMG3950.4508

Model HMG6353.4578

For all HMG models (with Front Toe-Kick styles as

shown at lower-right) adjust in this manner:

Loosen Adjustment Screws in Front Toe-Kick slots.

Adjust Front Toe-Kick up or down.

Tighten Adjustment Screws.

Lo

ck

ed

Un

lo

ck

ed

Location of Front Toe-Kick

Adjustment Screws

Fron

t Toe

-Kick

Deck

Approximate hole

locations pointed

at with arrows

( ) for bolting

units together.

Inner Sealant

Bead

Outer Sealant

Bead

Inner Sealant

Bead

Outer

Sealant

Bead