8

INSTALLATION: ADJUSTING LEVELERS / WIRING DIAGRAMS / FIELD WIRING CONNECTIONS

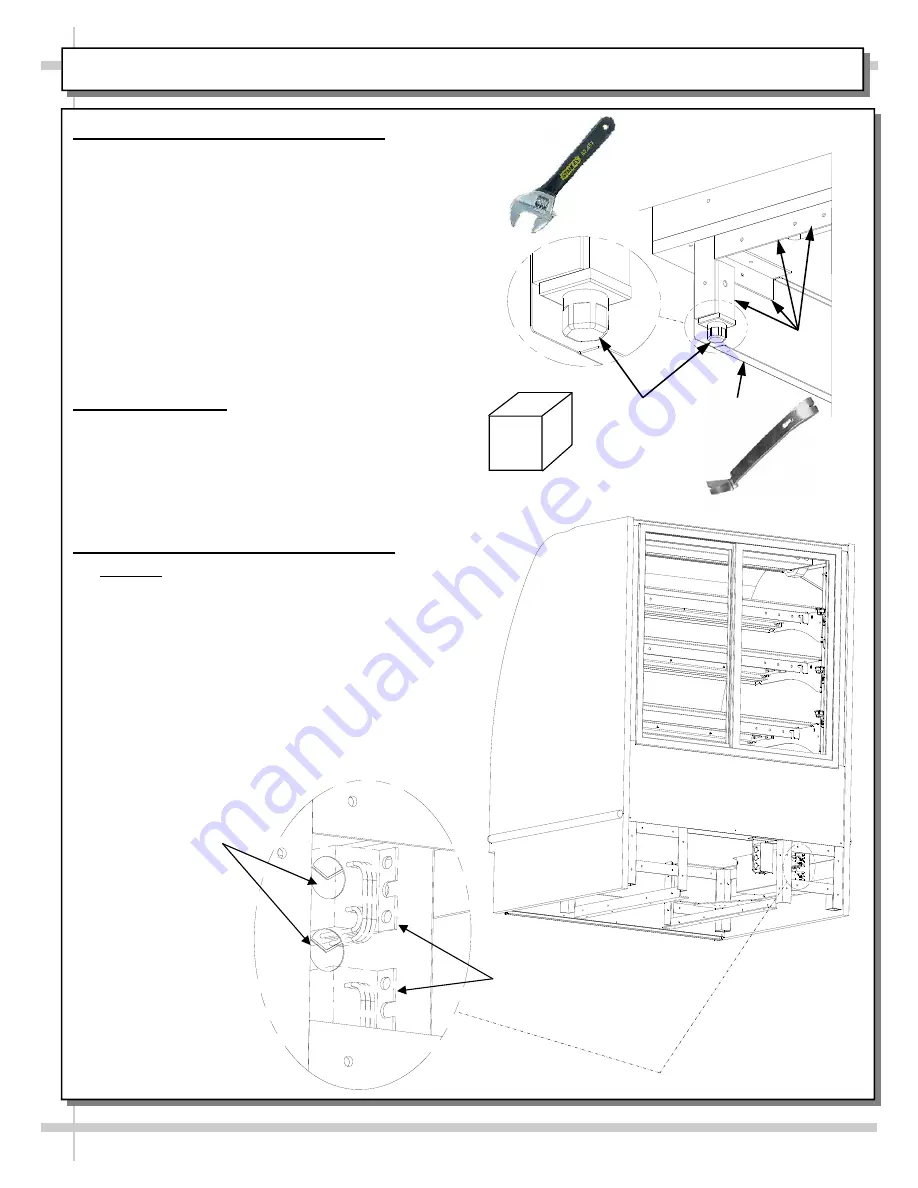

9. Cases With Levelers: Adjust Levelers

After case is in position, adjust case so it is level

and plumb (see illustration at right).

You may need to remove front and/or rear Toe

-Kick to access levelers.

Use adjustable wrench (and possibly a pry bar)

to adjust leveler.

Do not use pry bar on toe-kick (it may buckle).

Do not use pry bar on end panel (it may chip).

Use pry bar ONLY on base frame to avoid

damaging case.

Use block to reach base frames with pry bar.

See illustrations at right.

10. Wiring Diagram

Each case has its own wiring diagram folded and

in its own packet.

Wiring diagram placement may vary; it may be

placed near condenser fan cover, ballast box,

raceway cover, or other related location.

11. Field Wiring Connections (HMG3953)

Caution! Wiring process must be performed by

certified electricians only.

Remove ballast box face (by removing screws).

Remove screws from inner support.

Knockouts are located on side and rear of box for

making electrical connections.

Several ballast locations (depending upon model)

are shown in illustrations on this sheet.

Serial label (at case rear) lists voltage rating.

See next page for field wiring connections to

other models.

Pry Bar

Base

Frame

Leveler

Adjustable

Wrench

Toe-Kick

Block

Ballasts

Field wiring

connection /

junction box