Mis

c

e

lla

neo

us

17

Precautions

EN

Cleaning the Internals of the Printer

Perform thermal head cleaning if lines and marks appear

on printouts, and perform roller cleaning if scratches

appear at regular intervals.

Thermal head cleaning

To maintain print quality, we recommend that you perform

regular thermal head cleaning once a month or once after

every 10 printing packs used.

1

Make sure that the printer is not performing an

operation, and then pull out the media tray.

2

Confirm whether there is paper inside.

3

Remove the ink ribbon.

For details on how to remove the ink ribbon, see step

4 of “Replacing the Ink Ribbon and Paper” on

page 13.

4

Load the cleaning ribbon.

For details on how to load the cleaning ribbon, see

steps 2 and 3 of “Loading the Ink Ribbon and Paper”

on page 10.

Note

If there is any slack in the cleaning ribbon after it is

placed in the tray, take up the slack by turning the

spool in the direction indicated by the arrow in the

following figure.

5

Insert the media tray into the printer.

When the TRAY LOCK indicator is lit and the printer

finishes initializing, the RIBBON/PAPER indicator

flashes and cleaning starts automatically.

When cleaning is completed, the paper that was used

for cleaning is ejected and the TRAY LOCK indicator

is extinguished.

If you want to clean the rollers, proceed to “Roller

cleaning” on page 17.

If you are not cleaning the rollers, continue with the

steps below.

6

Make sure that the TRAY LOCK indicator is

extinguished then pull out the media tray.

7

Remove the cleaning ribbon.

8

Load the ink ribbon.

9

Insert the media tray into the printer.

Notes

• Store the cleaning ribbon in a location without dust (such

as in a bag).

• Place the removed media tray on a stable surface when

loading and removing the cleaning ribbon.

• Dropping the media tray while paper is loaded may

result in an injury. When pulling out and inserting the

media tray, hold the handle part with one hand and

support the media tray from the bottom with the other

hand, while making sure both of your hands are securely

holding the media tray.

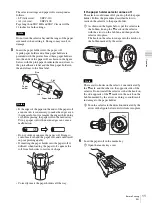

Roller cleaning

On rare occasion, scratches may appear at regular intervals

on printouts as shown in the following. These scratches

appear when the rollers inside the printer are dirty and

indicate that cleaning is necessary.

You can remove dust and other particles attached to the

rollers by using a cleaning sheet, which may be purchased

separately.

The following describes the cleaning procedure.

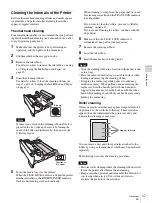

Notes

• Perform roller cleaning while the cleaning ribbon is still

inside the printer after thermal head cleaning.

• Keep a scratched printout and remember the direction it

was facing when ejected. You will need it later to

confirm the position of the scratches.

IC board

Direction to

turn spool

Regular intervals