0940-001-025 Rev-L

EN

www.stryker.com

9

Troubleshooting

WARNING:

DO NOT disassemble or service this equipment, unless

otherwise specified.

NOTE:

For service, contact your Stryker sales representative or call Stryker

customer service. Outside the US, contact your nearest Stryker subsidiary.

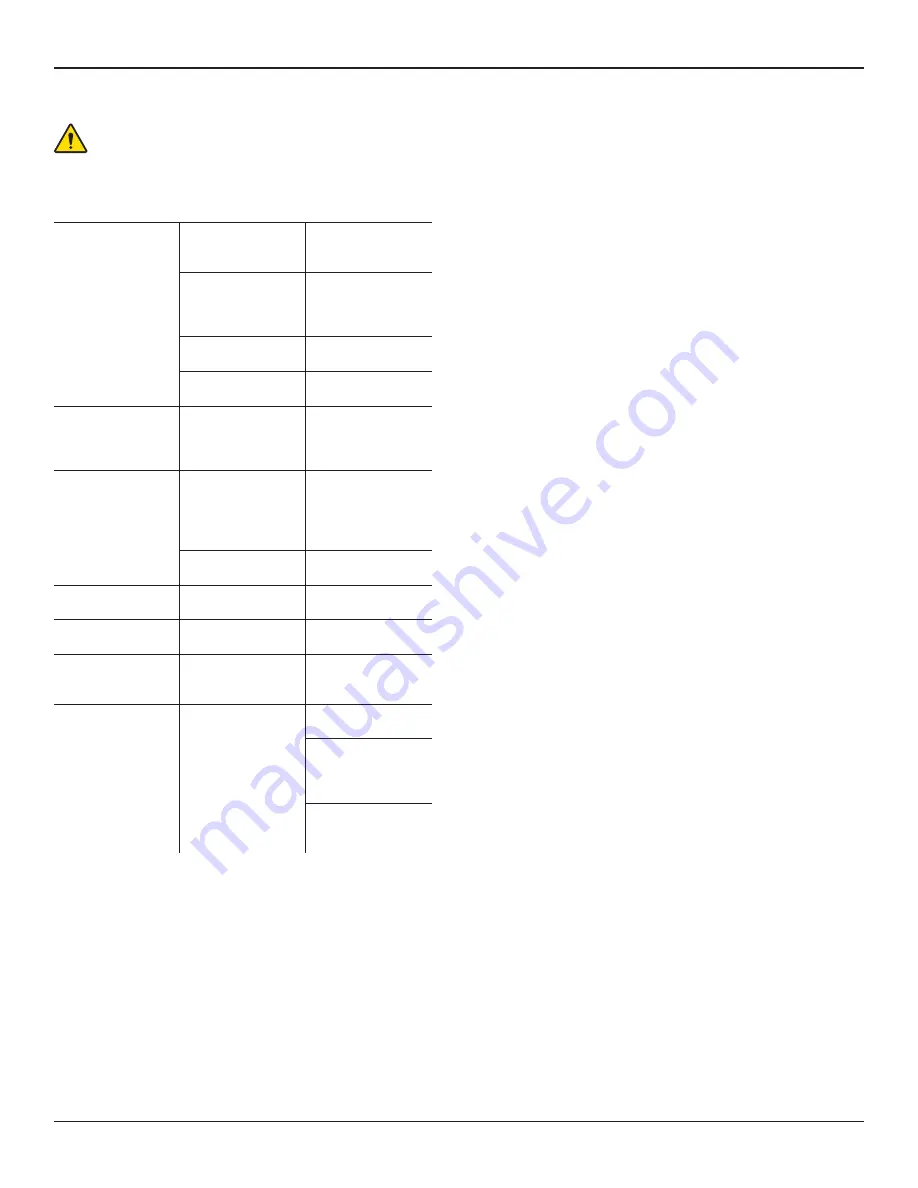

PROBLEM

CAUSE

SOLUTION

The Cast Cutter does

not operate.

The Cast Cutter is not

connected to facility

power.

See the

To Connect the

Cast Cutter to a Power

Source

section.

The motor brushes are

installed in the wrong

orientation.

Remove and install the

motor brushes. See the

Inspection, Testing, and

Maintenance

section.

The function switch is

broken.

Return the Cast Cutter

to Stryker for repair.

The fuse is blown.

Return the Cast Cutter

to Stryker for repair.

The Cast Cutter

operates at a very low

speed.

The motor brushes are

installed in the wrong

orientation.

Remove and install the

motor brushes. See the

Inspection, Testing, and

Maintenance

section.

The Cast Cutter does

not operate smoothly,

or operates with

excessive noise.

The motor brushes are

worn.

Replace the motor

brushes and springs.

See the

Inspection,

Testing, and

Maintenance

section.

The roller bearing is

worn.

Return the Cast Cutter

to Stryker for repair.

The blade does not cut

smoothly.

The blade is worn.

Replace the blade. See

the

Instructions

section.

The blade slips.

The blade guide posts

are worn.

Return the Cast Cutter

to Stryker for repair.

When used with a

CastVac, the level of

suction is reduced.

The vacuum hood is

blocked with debris.

Remove the debris from

the vacuum hood. See

the

Cleaning

section.

The equipment

experiences sporadic

electrical interference.

Electrical noise is

present.

Turn off all electrical

equipment not in use.

Relocate electrical

equipment; increase

spatial distance

between devices.

Connect electrical

equipment to different

facility power outlets.