0940-001-025 Rev-L

EN

www.stryker.com

7

Cleaning

WARNINGS:

▪

ALWAYS disconnect the power cord plug from the facility power outlet or

CastVac power outlet before cleaning the equipment. Failure to comply

may cause fire, electric shock, or injury.

▪

Upon initial receipt and before each use, clean and disinfect the

equipment as indicated.

▪

DO NOT sterilize the equipment.

▪

DO NOT immerse or soak the equipment in liquid. DO NOT flush the

internal vacuum line with liquid. DO NOT allow moisture or liquid to soak

into electrical plugs, receptacles, or openings. Moisture or liquid inside the

equipment may create an unsafe electrical condition, cause corrosion,

and/or damage the electrical and/or mechanical components.

▪

Before each use, make sure the equipment is completely dry. DO NOT

use any equipment if moisture is present.

▪

DO NOT use solvents, lubricants, or other chemicals, unless otherwise

specified.

To Clean the Equipment

1. Disconnect the power cord plug from the facility power outlet or CastVac

power outlet.

2. If the vacuum hood is blocked with debris, perform the following steps:

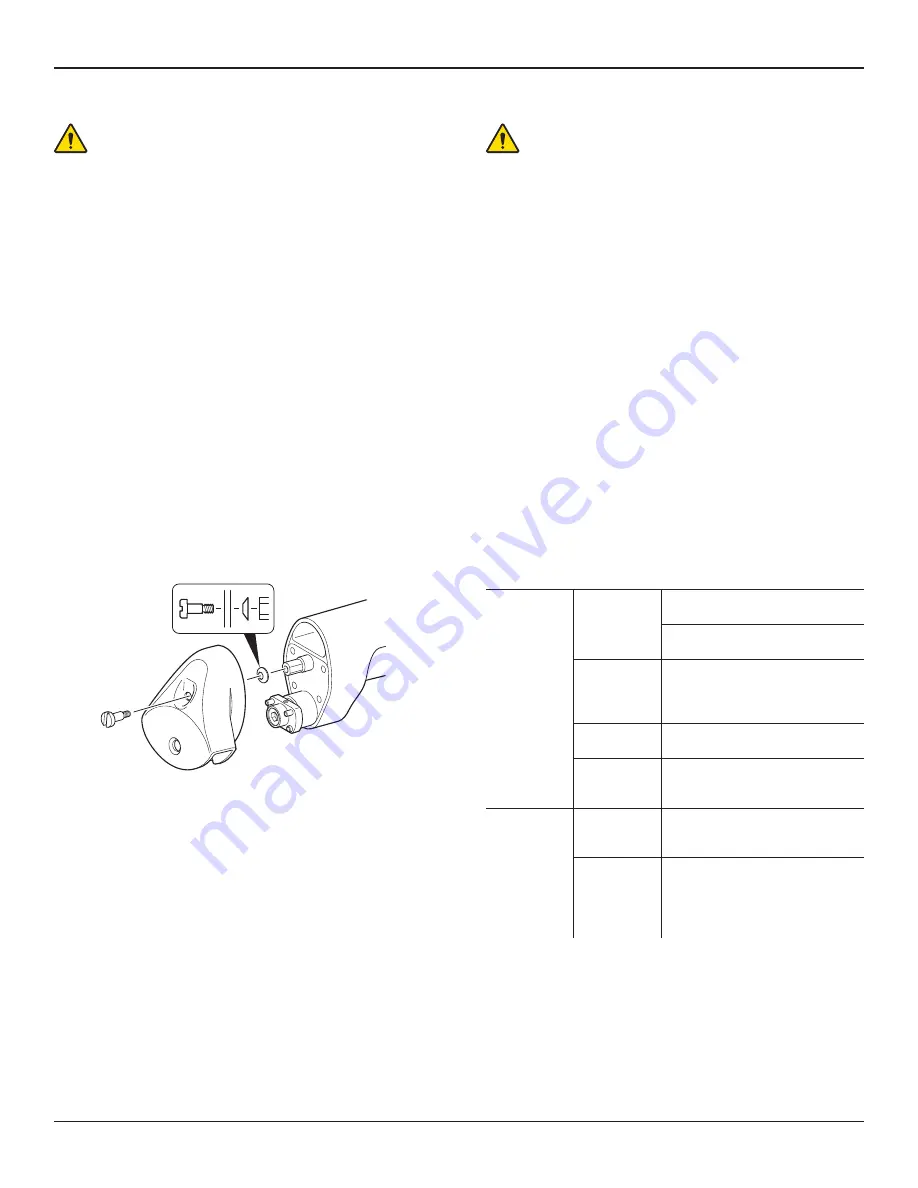

2. 1.

Use a standard slotted screwdriver to remove the captive screw,

Belleville washer, and vacuum hood.

2. 2.

Remove any blockage and wipe away the debris.

2. 3.

Reinstall the vacuum hood and Belleville washer, and securely

tighten the captive screw.

NOTE:

Make sure the Belleville washer is oriented correctly during

reassembly. See the illustration above.

3. Wipe the external surfaces of the equipment with a soft cloth moistened

with a non-abrasive, mild detergent and water.

4. Thoroughly dry the equipment with a soft, absorbent cloth.

To Disinfect the Equipment

1. Wipe the external surfaces of the equipment with a soft cloth moistened

with isopropyl alcohol. Blades can be disinfected with a standard

disinfectant.

2. Thoroughly dry the equipment with a soft, absorbent cloth.

Inspection, Testing, and Maintenance

WARNINGS:

▪

Only individuals trained and experienced in the maintenance of reusable

medical devices should inspect, test, and maintain this equipment.

▪

DO NOT disassemble or service this equipment, unless otherwise

specified. Failure to comply may cause fire, electric shock, or injury.

▪

ALWAYS disconnect the power cord plug from the facility power outlet or

CastVac power outlet before performing maintenance procedures on the

equipment. Failure to comply may cause fire, electric shock, or injury.

▪

Only the components listed in the

Inspection, Testing, and Maintenance

section are serviceable.

▪

When servicing or maintaining this equipment, use only Stryker-approved,

identical replacement parts.

▪

DO NOT use the Cast Cutter if the leakage current exceeds the

appropriate specification. See the

Specifications

section.

NOTES:

▪

The Cast Cutter has a lifetime lubrication system. No additional lubrication

is required.

▪

Calibration adjustments for the Cast Cutter were made during

manufacturing. No additional calibration is required.

▪

Maintenance documentation for this equipment is available upon request

to Stryker-authorized service personnel only.

▪

For service, contact your Stryker sales representative or call Stryker

customer service. Outside the US, contact your nearest Stryker subsidiary.

INTERVAL

ACTION

INSPECTION CRITERIA

Upon initial

receipt and

before each

use.

Inspect the

equipment.

If damage or excessive wear is

apparent, contact Stryker for repair.

If any components are loose or

missing, contact Stryker for repair.

Inspect the

power cord

and/or power

source cord.

If cracks, cuts, or damage is apparent,

contact Stryker for repair.

Inspect the

blade.

If the blade is dull, replace the blade.

See the

Instructions

section.

Operate the

equipment.

If unusual sound, excessive noise, or

vibration is apparent, contact Stryker

for repair.

Annually.

Actuate the

function switch

five times.

If the equipment does not operate

normally, contact Stryker for repair.

Use a

tachometer

to determine

the operating

speed.

If the equipment does not operate at

the proper speed, contact Stryker for

repair. For speed information, see the

Specifications

section.