60

IMPELLER

SEAL PLATE

SPACER SLEEVE

SPRING

STATIONARY

WASHER

STATIONARY

WASHER

BRASS SEAL LINER

LARGE CHAMFER

PACKING RINGS

ENGINE

CRANKSHAFT

STATIONARY

ELEMENTS

ROTATING

ELEMENTS

IMPELLER

SHIM

WASHERS

Figure 3. Grease Seal Assembly

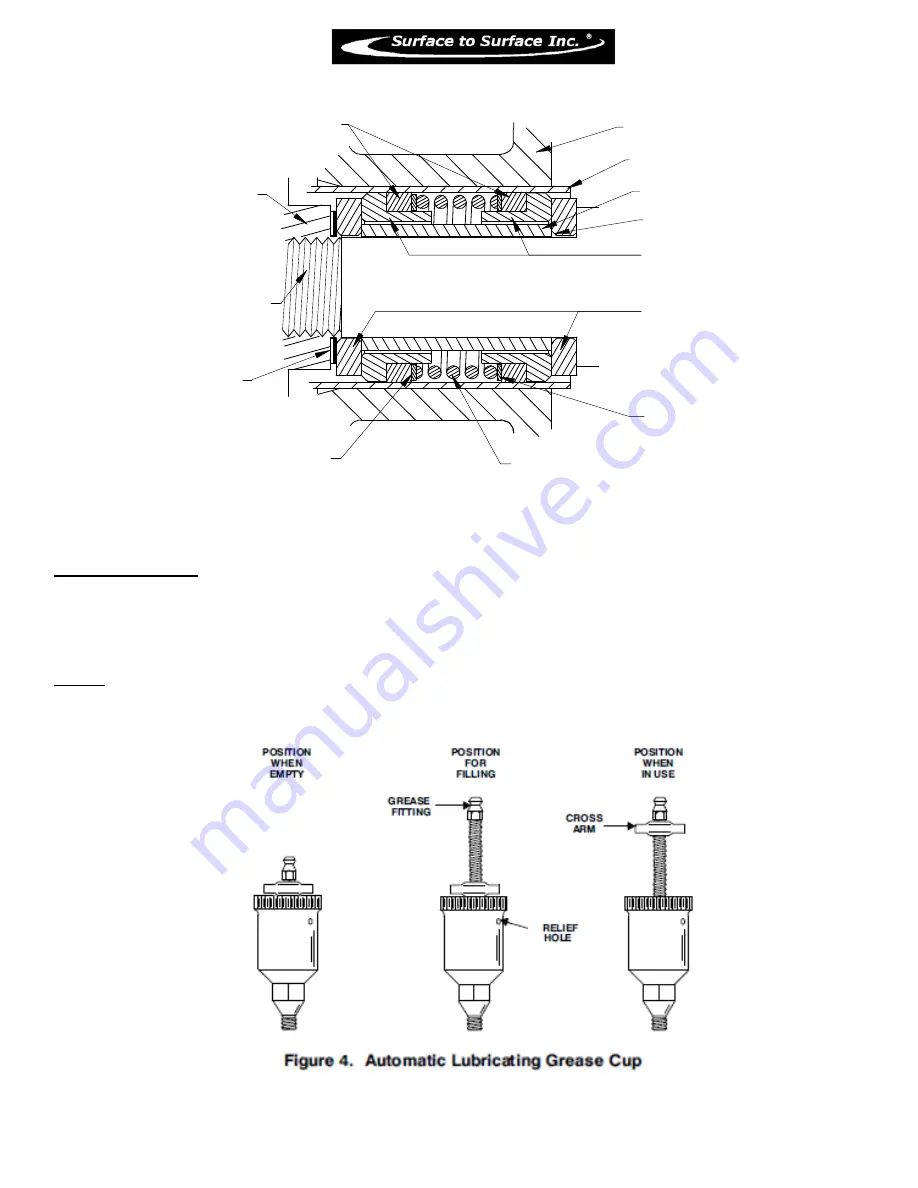

LUBRICATION

Fill the grease cup (1) through the grease fitting with No. 2 lithium base grease until grease escapes from the relief

hole. Turn the grease cup arm counterclockwise until it is at the top of the stem; this will release the spring to

apply grease to the seal (see Figure 4).

NOTE:

Some smoking and leakage may occur after installing a new seal assembly. This should stop after the

pump has run a while and the lapped seal faces have seated in

Figure 4. Grease cup

Summary of Contents for M2-H

Page 2: ...2 This page left blank intentionally ...

Page 13: ...13 ...

Page 18: ...18 M2 H Identifying Your Machine Components Location of Tags and PIN Plates ...

Page 19: ...19 SECTION II Description Care and Maintenance ...

Page 31: ...31 SECTION III Set up and Installation of Unit in Detail ...

Page 33: ...33 SECTION IV Operating the M2 Unit ...

Page 41: ...41 SECTION V Troubleshooting the M2 Unit ...

Page 44: ...44 SECTION VI Periodic Maintenance Repair Information ...

Page 49: ...49 SECTION VII OEM Repair Information ...

Page 62: ...62 ...

Page 63: ...63 ...

Page 64: ...64 ...

Page 68: ...68 SECTION VIII Parts Manual ...