SPECIFICATIONS

AND

FEATURES

StudPro XI-

Capacitor Discharge Stud Welder Series

The

StudPro XI

series of capacitor discharge stud welders incorporates the latest solid state

technology into a compact, lightweight, and rugged CD stud welder. This full line of equipment is

capable of welding pins, cup head pins, and CD studs ranging from 14

-

gauge up to 3/8” full

-

flanged

stainless steel studs.

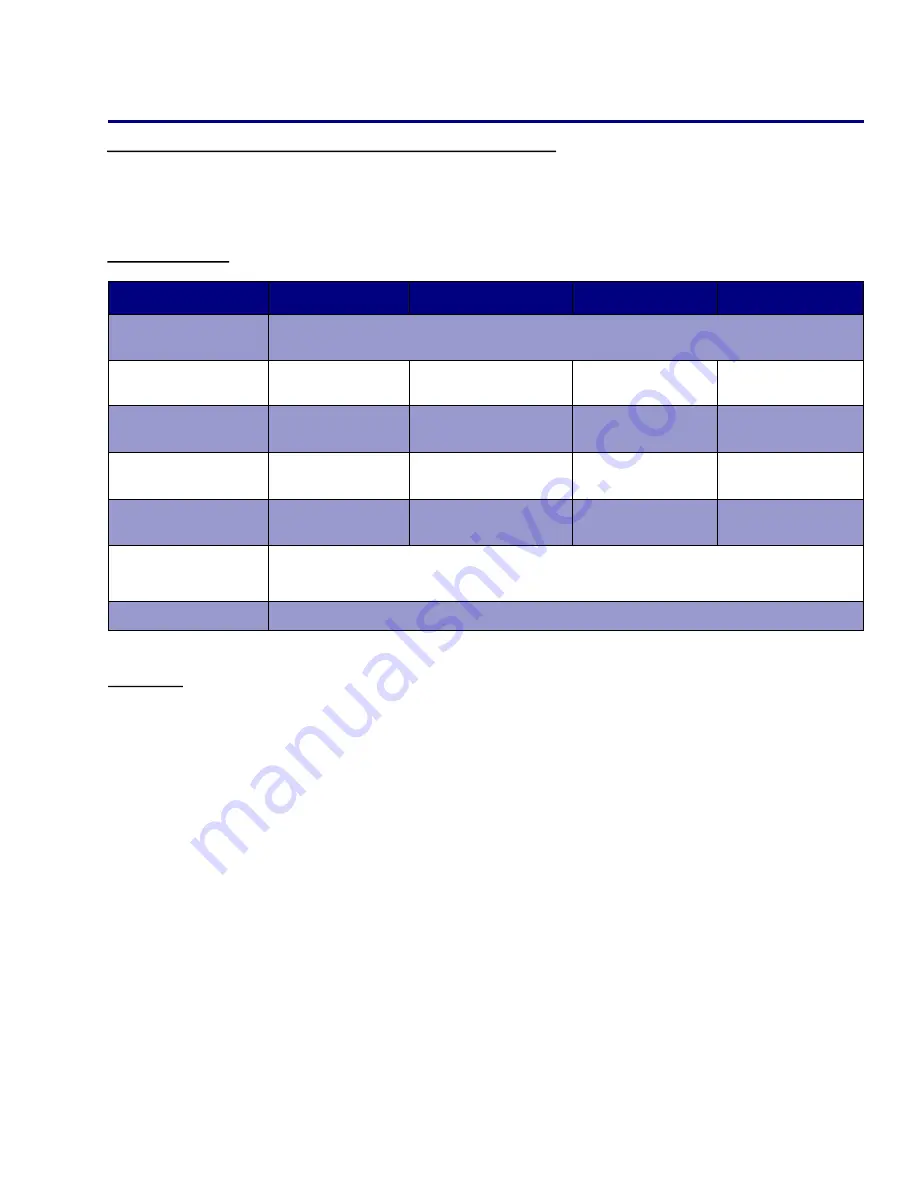

Specifications

Features

•

Intuitive Touchscreen Interface with preset values for fast, accurate, and repeatable weld settings

•

Set

-

Point Discharge: Unit discharges directly to a new set point without needing to discharge com-

pletely

•

Universal Input Voltage: Plug and play, no need to re

-

tap the machine for 110V or 220V input volt-

ages

•

Low input voltage capability enables operation with long extension cords

•

Contact and Trigger indicators for fast troubleshooting of hand tool and weld cable maintenance

issues

•

Thermal and Voltage protection indicators to protect the unit from damage due to overheating or

poor input power

•

Rigid internal construction minimizes the possibility of components coming loose during rough han-

dling or operation

•

Hand tool has been ergonomically designed to reduce operator fatigue for increased welding effi-

ciency

•

Hand tool has an adjustable internal spring to apply the correct spring pressure for every welding

application

•

Hand tool can be configured for B collets, CI (Collet Inserts), Euro collets, or standard tapered

chucks

SPECS

StudPro 2500XI

StudPro 2500XIP

StudPro 3125XI

StudPro 3750XI

SIZE

14” L, 10.5” W, 11.5” H

356mm x 267mm x 292mm

WEIGHT

(Power Supply Only)

18 lbs. (8.1Kg)

18 lbs. (8.1Kg)

20.8 lbs. (9.4Kg)

23.4 lbs. (10.6Kg)

CAPACITANCE/ENERGY

76,000µF/1520Ws

76,000µF/1520Ws

114,000µF/2280Ws

152,000µF/3040Ws

WELD RANGE

14Ga

-

1/4” Stainless

14Ga

-

1/4” Stainless

(including cup head pins)

14Ga

-

5/16” Stainless

14Ga

-

3/8” Stainless

DUTY CYCLE

18 studs per minute

(1/4” settings)

18 studs per minute

(1/4” settings)

14 studs per minute

(5/16” settings)

10 studs per minute

(3/8” settings)

PRIMARY POWER

(Universal Input)

85

-

250 VAC, 6.0

-

2.0A, 50/60Hz

CHARGE VOLTAGE

35

-

200 VDC

3

* Specifications are subject to change without prior notification

WWW.STUDWELDPROD.COM

800-252-1919