A730 CD Player

16.11.00 BN

Upgrade Kit 1.630.027.81

Page 2 of 7

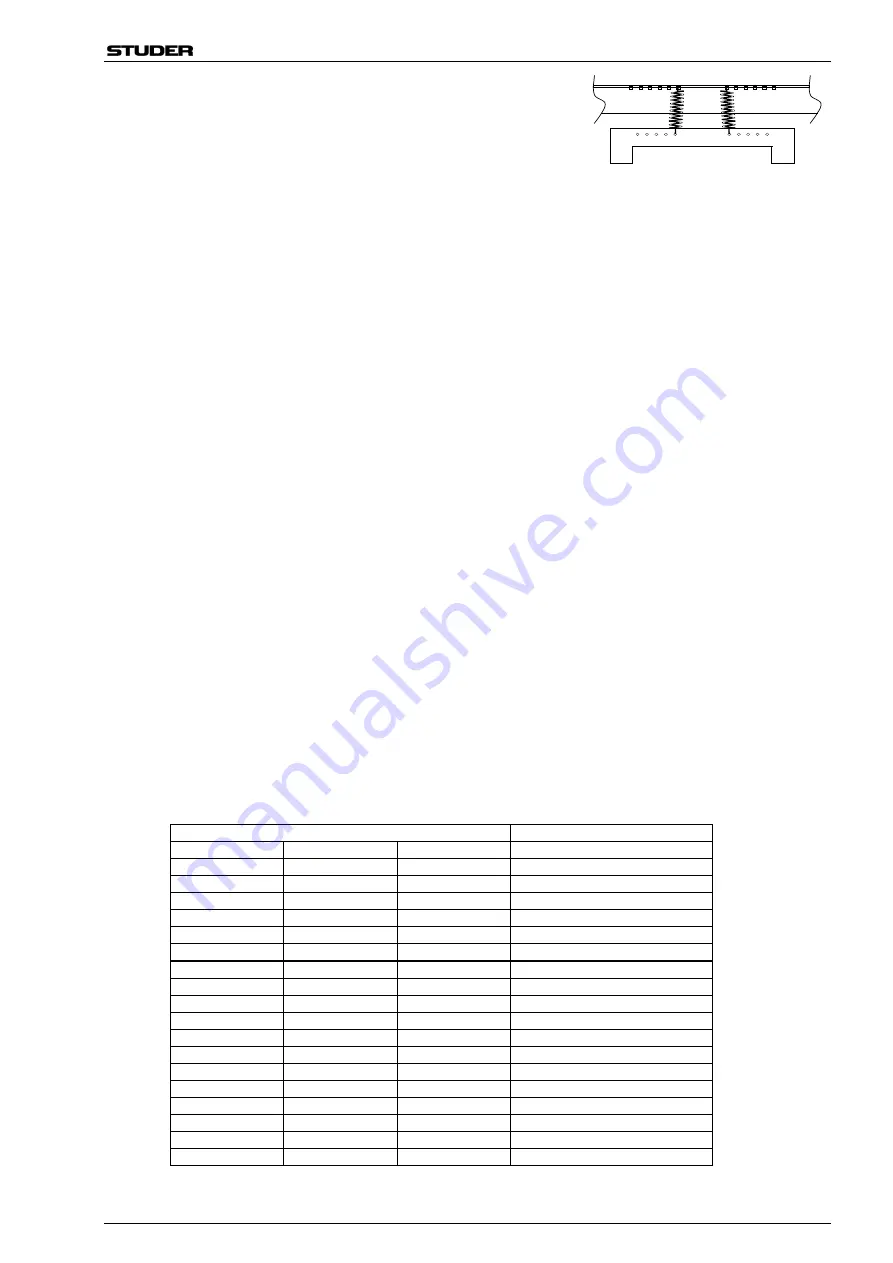

Bracket on front panel

CD drive

•

Fit the two tension springs put aside before according to the figure;

the spring mounting holes are partially covered by the CD drive

frame.

Position of the CD drive

•

The exact position of the CD drive is important. For adjustment, the front panel must be placed to the bottom

of the player. Check with an inserted CD if the air gap is of equal width around the circumference of the disk.

If so, tighten the four screws linking the CD drive frame with the front panel.

Servo Board Modification

•

Remove the insulating sheet and all remainders of the adhesive foam tape from the solder side of the board

(1.630.051.85/86). Put the insulating sheet aside for later use.

•

Perform the following modifications on the Board (1.630.051.85/86): R48 (22 k

Ω

), replace by 10 k

Ω

(57.11.3103); R16 (270 k

Ω

), replace by 130 k

Ω

(57.11.3134); R17 (51 k

Ω

), replace by 22 k

Ω

(57.11.3223);

C21 (68 pF) , replace by 330 nF (59.06.0334) in series with 56 k

Ω

(57.11.3563).

•

Remove the following parts: TP17, TP18, TP24, TP28, J1, J3, J7, C66, R73 (trimmer pot), and IC6.

•

The 100 nF capacitor (59.03.2104) is connected to TP19 (HF-RET); its second terminal is soldered to the

solder lug (29.26.1002), refer to fig. 1. Test points TP2 and TP3 must be bent by 90°, refer to fig.1; we ur-

gently recommend to unsolder them before bending.

•

Solder the pre-fabricated wires (1.630. 114.93) to the corresponding solder pads according to the table be-

low and to fig. 1 (at the former positions of connectors J1 and J3). Tie the cables with the wire straps

(35.03.0109) according to fig. 4 and 5. Solder the two twisted wires (brn, blk) to the corresponding pads on

the PCB (refer to the table below and to fig. 1).

•

Solder the small Driver Brush Motor PCB (1.630.075.00) at the location of IC6. The ZIP connector for the flex

PCB and its wires will be located between the Driver Brush Motor PCB and the Servo Board, therefore

please leave sufficient space between the two PCBs. For details please refer to fig. 1 and 4.

•

Caution:

The clearance between the CD drive and the Servo Board is extremely narrow; therefore the com-

ponent leads on the solder side marked grey in fig. 3 must be cut very short.

•

Cut a rectangular insulating sheet (dimensions: 122 x 100 mm) out of the insulating sheet put aside before;

refer to fig. 1. Fix this insulating sheet as shown in fig. 3 to the solder side of the Servo Board, using five

pieces of the double-sided adhesive foam tape contained in the kit. The foam tape has to be positioned ac-

cording to fig. 1 and 3; press the insulating sheet firmly to the foam tape.

•

Drill two holes

∅

3.2 mm into the insulating sheet such that they match the two mounting holes of the PCB.

•

Fold the flat ribbon cable as shown in fig. 1. Stick the label “1.630.072.00” over the label “1.630.051.86” and

solder the two twisted wires to the motor’s soldering tags (brn wire to red dot).

•

Reinstall the Servo Board, using the four 2 mm spacers (1.010.165.27) between mounting frame and Servo

Board. Fix the Servo Board with the three M3×8 screws (21.53.0355), and the countersunk screw M3

(21.99.0121) next to the Driver Brush Motor PCB.

•

Connect the Flex PCB to the ZIP connector. After having locked the connector (shift the locking clip towards

the wire end of the connector), it must be fixed to the Servo Board using a piece of double-sided adhesive

foam tape. Position the connector exactly as indicated in fig. 4 –

the flex PCB of the CD drive as well as the

two wires to the motor must be free in all directions – it must by no means be under tensile stress.

•

If using the additional Service Kit 1.630.060.00, replace the 3-pin housing of the lock solenoid connector

(plugged to socket J4) by the 5-pin housing contained in the kit, refer to fig. 7.

Source

Destination

J1, pin no.

Signal name

Wire color

Conn. CDM-4 (ZIF), pin no.

1

GND

brn

14

2

D1

red

10

3

D2

org

9

4

D3

yel

11

5

D4

grn

12

6

S

blu

13

7

G

vio

8

8

FOC-

gry

1

9

FOC+

wht

2

10

LO

blk

6

11

LM

red

7

12

LG

org

5

J3, pin no.

Signal name

Wire color

1

RAD+

brn

3

2

RAD-

red

4

TP

Signal name

Wire color

DC-Motor, pin

24

+5V

brn

red

dot

28

VM

blk

no mark