3

© STULZ GmbH – all rights reserved EN/04.2017

electrical optioNS

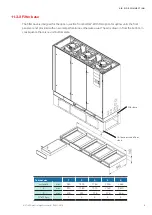

11.5.2 Second Power Supply

This option provides the connection of a second power supply. Both power supplies are switched on to the

A/C unit. A contactor circuit ensures that the priority is set on power supply 1.

All three phases of both power supplies are checked constantly on excess voltage, undervoltage, phase fail-

ure, phase balance and correct rotation. In case of failure of supply 1 the unit is switched off. After a lapse of

time which can be set at the time relay (preadjusted: 10 seconds) power supply 2 is switched onto the unit.

The unit starts by the automatic restart which is integrated in the controller.

When the voltage of power supply returns, the unit is switched off again. On a second time relay a delay can

be set (preadjusted: 10 seconds), after which power supply 1 is switched onto the unit. The unit starts by the

automatic restart.

S4: Setting the limit values for undervoltage release

S5: Setting the limit values for excess voltage release

S6: Setting the limit values for phase imbalance

Function only for three-phase networks available.

S7: Setting the rotating field control

Function only for three-phase networks available.