© STULZ GmbH, Hamburg

EN / 10-2015 / 1000683

-

33

-

STULZUltraSonic-SystemforDirectRoomHumidificationBNB-

Installation

7.

Installation

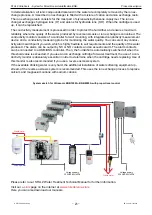

Install the unit in such a way that the mist expelled by the fan is distributed uniformly everywhere in the

room. Please check that the product package is complete before installation

.

CAUTION

Danger of death. Electric shock risk.

Faultywiringoftheswitchgearcabinetcancausethehumidifiertobecomedefective.

The

STULZ

UltraSonicBNBultrasonichumidifier may only be installed, connected and started up by

specialist electricians.

●

Switch gear cabinets must be wired as shown in the wiring diagrams provided.

WARNING

DANGER

CAUTION

Genuine parts.

Use only genuine STULZ parts and genuine spare parts for installation.

CAUTION

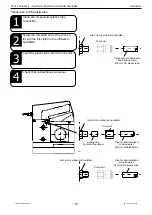

Horizontal position.

The unit must be mounted precisely horizontally.

●

Itisessentialtocheckthepositionofthehumidifierbeforestartingitup!

NOTICE

CAUTION

Upright position.

Do not switch on the master switch under any circumstances if the unit is

not

in an upright position.

●

Itisessentialtocheckthepositionofthehumidifierbeforestartingitup!

NOTICE

CAUTION

Adhere to set clearances.

Between the mist guide tube and any component that may be located in front of the unit, leave a clear-

ancethatisgreaterthanthehumidifierdistance.

●

See section "5.1.Humidifierdistance"onpage27.

NOTICE

CAUTION

Installation clearance.

Leaveminimumclearanceof500mmbetweentheupperedgeoftheultrasonichumidifier

and the ceiling.

●

See section "7.2. Installation clearances" on page 36.

NOTICE

CAUTION

Minimum distance between units.

When several units are installed in a room, maintain a minimum distance of 300 mm between them.

●

See section "7.2. Installation clearances" on page 36.

NOTICE