(Mar, 2012)

CeilAiR OHS Series Installation, Operation & Maintenance Manual

Air Technology Systems, Inc.

2.0 Installation

2.1 Receiving the Equipment

Your

CeilAiR

OHS system has been tested

and inspected prior to shipment. To ensure that

your equipment has been received in excellent

condition, make a visual inspection of the equipment

immediately upon delivery. Carefully remove the

shipping container and all protective packaging.

Remove the access panels and thoroughly inspect

the unit interior for any signs of transit-incurred

damage. If there is shipping damage, it must be

noted on the freight carrier’s delivery forms BEFORE

signing for the equipment. Any freight claims MUST

be done through the freight carrier. SATS ships all

equipment FOB. SATS can assist in the claim fi ling

process with the freight carrier. Should any damage

be present, notify the SATS Product Support Group

prior to attempting any repairs. Refer to section fi ve

of this manual for instructions.

A unit Data Package has been sent with your unit. It

contains this manual, system drawings, applicable

MSDS’s, other component manuals and any other

applicable instructions based on the confi guration

and options of your unit. The data package has been

affi xed to your unit in a clear plastic bag. These docu-

ments need to be kept with the unit for future service.

NOTE

Items that have been shipped loose such as

controllers, humidistats, vibration isolators,

buck/boost transformers, etc. are shipped

inside the air conditioner unless specified

otherwise by the customer. Grilles (if applicable)

are placed on top of the air conditioner inside

the unit’s carton. Remove and store these items

in a safe place unless you are using them im-

mediately.

2.2 Site Preparation

CeilAiR

systems are designed with easy service

access in mind. Component access panels are

located on the front and rear sides of the equipment.

Additional access to some components may be

obtained through the bottom of the unit on spot

cooler confi gurations. These units can be fully

serviced in the ceiling plenum. In order to have full

service access, the air conditioner must be located

so that adequate space is provided in front of all

access panels.

NOTE

Working clearance requirements need to be

established prior to the mounting of the unit.

Refer to local and national electrical codes.

To minimize the effects of the environment

surrounding the conditioned space, certain steps

must be taken. This is especially true for critical/

precision room preparation (computer rooms/labs)

requiring close tolerance control of temperature

and humidity. The conditioned space should be well

insulated and include a vapor barrier. The installer

should ensure that the proper insulation rating is

used based on the design of the space, which was the

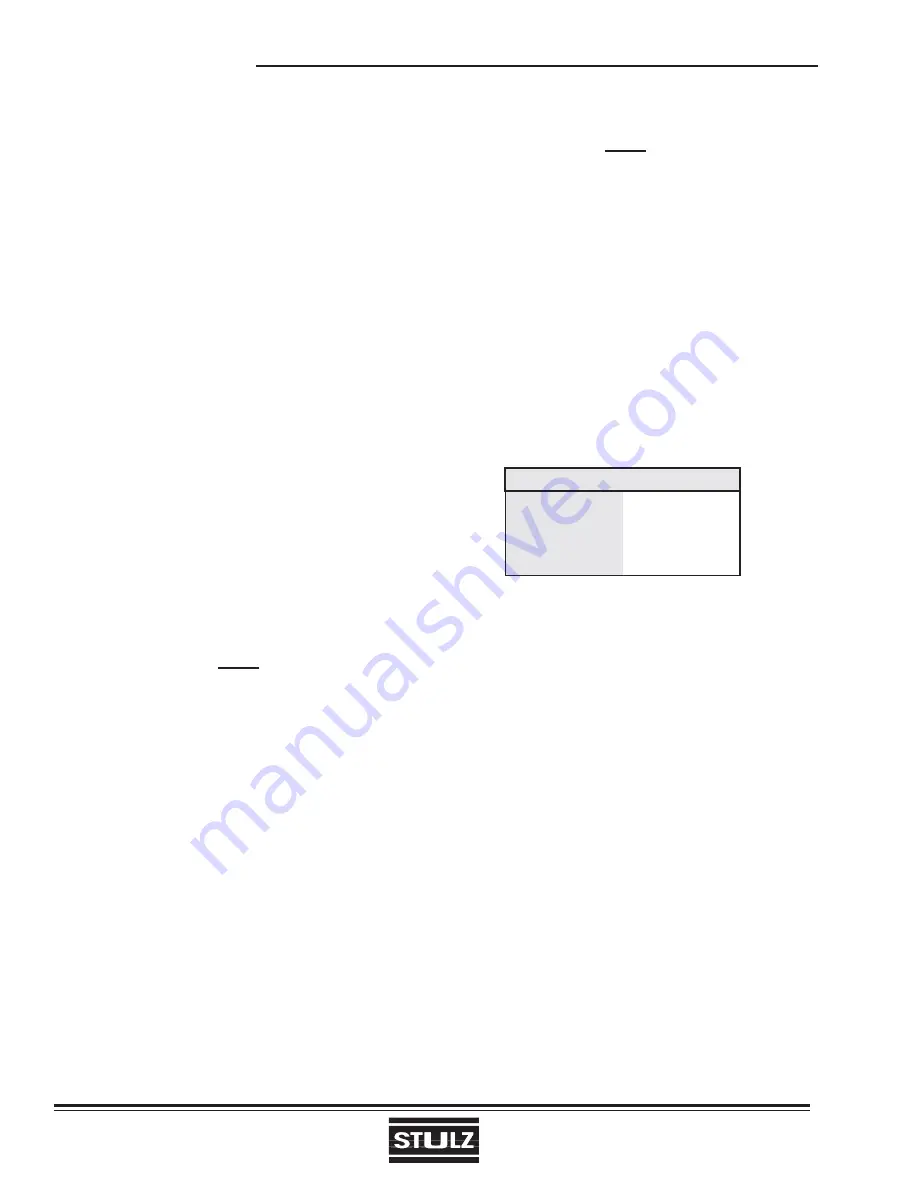

basis for the system selected. The following chart is a

recommended minimum R-value (thermal resistance) to

ensure optimum equipment operation.

The vapor barrier is the single most important

requirement for maintaining environmental control

in the conditioned space. The vapor barrier in

the ceiling and walls can be polyethylene fi lm.

Concrete walls and fl oors should be painted with a

rubber or plastic-based paint. Doors and windows

should be properly sealed and a door sweep used

to minimize leakage. Outside or fresh air should

be kept to a minimum (as it adds to the cooling,

heating, dehumidifi cation and humidifying loads),

while maintaining the requirement of the Indoor Air

Quality (IAQ) Standard. Lack of these steps can

cause erratic operation, unstable room control and

excessive maintenance costs.

2.3 Rigging

CeilAiR

systems are designed to be kept in a

horizontal position. The unit is shipped on a skid to

facilitate moving prior to installation. A suitable lifting

device should be used to lift the unit from the bottom.

A weight table is provided for reference on the

installation drawing. The unit should always be stored

indoors in a dry location prior to installation.

STRUCTURE R-VALUE

Ceiling

R-38

Wall

R-21

Floor

R-19

Door

R-5

2-1