(Mar, 2012)

CeilAiR OHS Series Installation, Operation & Maintenance Manual

Air Technology Systems, Inc.

2-8

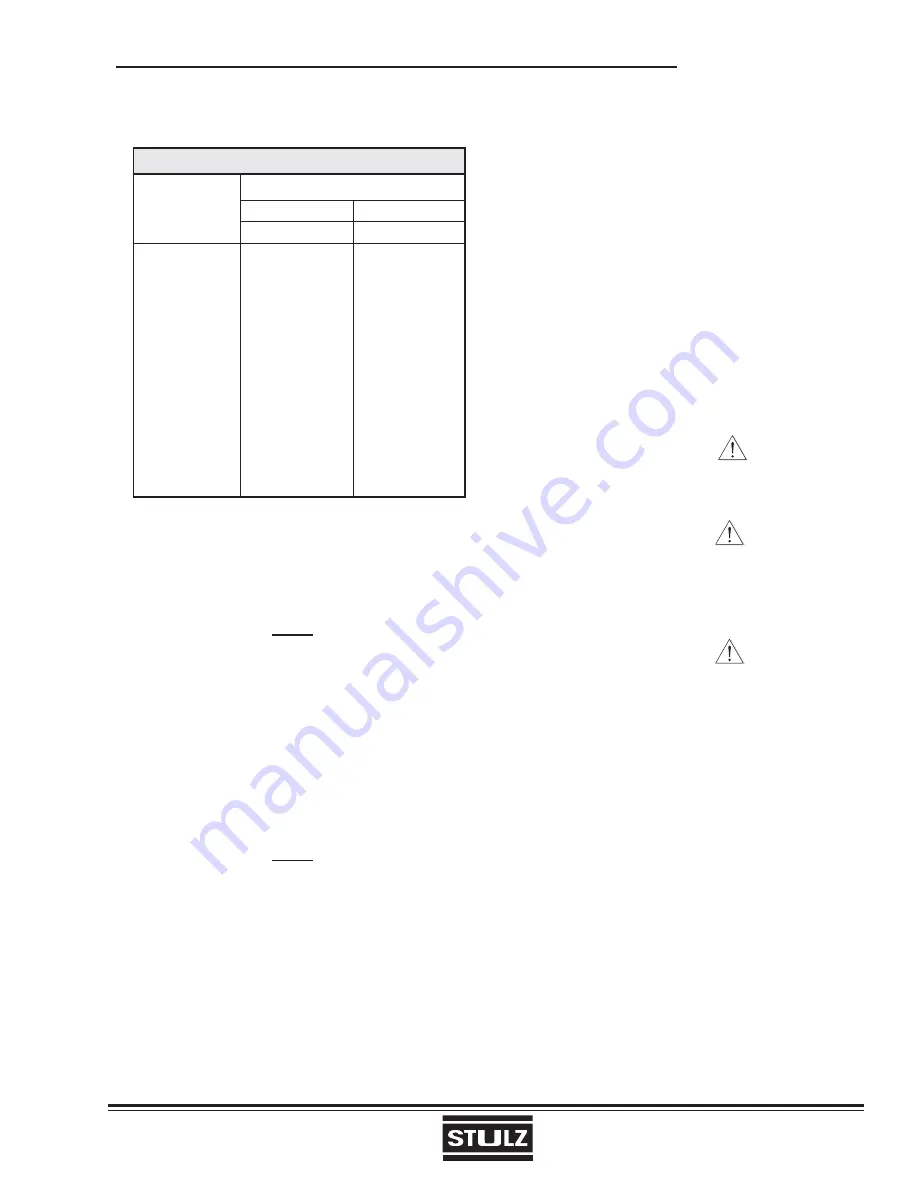

H = Horizontal Run

V = Vertical Run

RECOMMENDED SUCTION LINE SIZES

Model No./

*Equivalent Length Ft.

Total Unit Capacity

50’or less

100’or less

H V

H V

012 /

12,000

5/8

5/8 5/8 5/8

018 /

18,000

7/8

7/8 7/8 7/8

024 /

24,000

7/8

7/8 7/8 7/8

032 /

32,000

7/8

7/8

1-1/8

7/8

040 /

40,000

7/8

7/8

1-1/8

1-1/8

048 /

48,000

1-1/8

1-1/8

1-1/8

1-1/8

048

D

/

48,000

7/8 7/8 7/8 7/8

060 /

60,000

1-1/8

1-1/8

1-1/8

1-1/8

072

D

/

72,000

7/8 7/8 1-1/8 7/8

084

D

/

84,000

1-1/8 1-1/8 1-1/8 1-1/8

120

D

/

120,000

1-1/8 1-1/8 1-1/8 1-1/8

Vertical runs are based on a total rise of 30 equiva-

lent feet. For longer rises, individual calculations

should be made. Sizes assume the use of single

risers; double rises may be necessary.

NOTE

Consult the Copeland applications data guide

for more detailed information regarding refriger-

ant line traps and line sizing.

2.6.1.2.2 Remote Air Cooled Condensing Units

(AHU

Models)

Systems utilizing a remote condensing unit (RCU)

will require a copper liquid line and suction line.

When installing remote condensing units above the

evaporator, the suction line should be p-trapped at

the evaporator.

NOTE

Do not exceed 15 feet of vertical distance

when installing the condensing unit below the

evaporator.

When installing remote condensing units below the

evaporator, the suction line should be trapped with

an inverted trap the height of the evaporator coil. This

prevents migration of liquid refrigerant to the com-

pressor during off cycles.

All suction lines must be insulated to prevent conden-

sation from forming on the pipes. Refer to provided

pipe size charts for recommended pipe sizing.

2.6.2 Chilled Water, Water/Glycol and Hot

Water Reheat Piping

The piping connections for water/glycol, chilled water

and systems with hot water reheat are sweat connec-

tions. Pipe sizes may not necessarily be the same

as the unit connection. Piping should be sized to

match the system pressure drop and pump capac-

ity (if applicable) and may require reducing fi ttings to

match the connection size on the air conditioner. The

recommended ethylene glycol solution ratio is 40%

glycol to 60% water. (SATS recommends Dowtherm

SR1 manufactured by Dow Chemical Co.) Glycol-

cooled systems with a low entering fl uid temperature

and all chilled water systems should have insulated

piping.

WARNING

Glycol is hazardous and the manufacturer’s

MSDS should be consulted.

CAUTION

When installing and fi lling the water/glycol,

chilled water and optional hot water reheat

loop, all air must be bled from the piping

system.

CAUTION

The piping system must be fl ushed prior to op-

erating the system. Failure to do so will result

in equipment problems.

A strainer should be included in the water/glycol,

chilled water and optional hot water reheat line. Once

the system is operational, the fl uid runs through the

strainer where any foreign objects are removed. The

strainer screen should be cleaned periodically.