(© Oct, 2007)

Compact CW Series Installation, Operation & Maintenance Manual

Air Technology Systems, Inc.

4-1

4.0

MAINTENANCE

4.1

Periodic General Maintenance

Systematic, periodic general maintenance of the

Compact CW unit is recommended for optimum

system performance. General maintenance should

include, but is not limited to the following: replacing

filters and humidifier cylinders, tightening electrical

connections, checking the water lines to ensure they

are free of debris, ensuring no air is in the water

line(s), cleaning the interior of the unit, checking belt

tension and inspecting the unit’s components visually.

Use copies of the Periodic General Maintenance

Checklist in this manual (see Appendix A) to record

periodic general maintenance inspections. For

assistance, contact the SATS Product Support Group.

Ensure adherence to all safety statements while

performing any type of maintenance.

WARNING

This equipment should be serviced and repaired

by a journeyman or a qualified refrigeration

technician only.

WARNING

This unit employs high voltage equipment with

rotating components. Exercise extreme care to

avoid accidents and ensure proper operation.

Hazardous voltage will still be present inside the

electric box at the motor start protectors and at the

heater and humidifier circuit breakers, even with the

unit turned off at the microprocessor controller. To

isolate the unit for maintenance, turn off power at the

main power disconnect switch. Always disconnect

main power prior to performing any service or repairs.

WARNING

Turn off power to the unit unless you are per-

forming tests that require power. With power and

controls energized, the unit could begin operat-

ing at any time. To prevent personal injury, stay

clear of rotating components as automatic con-

trols may start them unexpectedly.

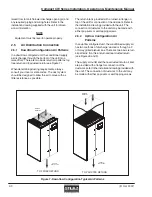

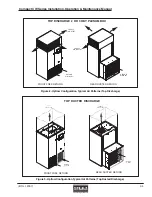

4.1.1

Compact CW Precision A/C Unit

4.1.1.1 Filter

The filter is usually the most neglected item in an air

conditioning system. To maintain efficient operation,

the filter should be checked at least monthly and

replaced as required.

NOTE

Air quality conditions of spaces vary and filters

should be checked based on those conditions.

4.1.1.2 Blower

The blower motor is provided with permanently lubri-

cated bearings and should not require maintenance for

the lifetime of the equipment. Periodic checks of the

blower system should include checking the blower

motor mounts, housing, belts and blower wheel.

Check that all mounts are secure and the blower

wheel is tightly mounted on the shaft and does not rub

against the fan housing. The blower vanes should be

kept free of debris.

4.1.1.3 Drain Pan

To ensure proper drainage, inspect the drain pan

regularly. Make sure the drain pan outlets are always

free of debris and ensure the drain pan does not leak.

4.1.1.4 Coils

The coil(s) should be inspected semi-annually and

cleaned as required, following standard coil cleaning

practices. Using a brush, clean the coil fins of all

debris that will inhibit airflow. This can also be done

with compressed air or with a commercial coil cleaner.

Check for bent or damaged coil fins and repair as

necessary. Check all piping for signs of leaks.

4.1.1.5 Heat/Reheat

The heat/reheat equipment should be inspected semi-

annually to ensure it is operational. If you have electric

heat/reheat, inspect the heating elements to ensure

they are free of debris.

4.1.1.6 Humidifier

The steam cylinder has a limited lifetime and must be

replaced periodically. Because water conditions and

humidifier usage rates vary greatly, it is difficult to

establish intervals for changing the cylinder. Individual

maintenance schedules must be determined for each

location, based upon periodic examination of the