40

M4 M3 M2 M1

M8 M4

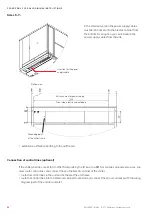

Modell

M1

M2

M3

M4

M5

M6

M7

M8

CSO 1102 ASN

kg

139

254

233

135

148

280

256

148

CSO 1302 ASN

kg

146

269

248

146

150

282

260

150

CSO 1102 ASF

kg

148

267

245

146

209

389

356

209

CSO 1302 ASF

kg

155

276

253

154

215

399

366

216

CQO 802 ASN

kg

121

213

229

115

140

270

246

143

CQO 1102 ASN

kg

140

256

235

136

149

282

258

149

CQO 802 ASF

kg

135

246

229

124

199

380

348

210

CQO 1102 ASF

kg

150

270

248

148

211

393

360

211

EN/09.2019/G42 © STULZ GmbH – all rights reserved

cybercool 2 scroll original insTrUcTions

Construction size 4

Bottom view

right

left

front

Air inlet zone

The weights are indicated with a tolerance of ±5%.

Model