82

EN/09.2019/G41 © STULZ GmbH – all rights reserved

cybercool 2 screw original insTrUcTions

Expansion valve

The refrigerant circuit is equipped with an electronic expansion valve, which controls the superheating in the

evaporator. The superheating is adjusted to 5 K at the factory and may not be modified.

• Check the superheating setpoint.

• Check the superheating by the command "eev 1" in the first refrigerant circuit resp. "eev 2" in the second

refrigerant circuit. If the superheating is below 3 K or above 7 K for a longer time, the function of the expan

-

sion valve is faulty.

• Check whether the refrigerant, pressure sensor and valve type are correctly set in the C7000.

The following valve type "Carel EXV" (valve type: 1) must be set. The following pressure sensor "-1...9,3

barg" (Sensortype evaporating pressure: 3) must be set.

• Switch off all components of the refrigerant circuit and control the expansion valve in manual mode.

• Through control of the sight glass on the valve, check the mechanical operation of the valve.

• Compare the suction pressure measured by the valve sensor with the value of the suction pressure gauge in

the compressor section. Compare the suction gas temperature measured by the valve sensor, with the value

of a reference sensor at the suction line.

If you can find no deviation at all checks, probably the control module of the valve is defective and must be

replaced.

The expansion valve can freeze, if the humidity in the refrigerant circuit is excessive.

dAngER

do not thaw by soldering flame, danger of explosion !

Thaw with moist warm cloth. Check the sight glass.

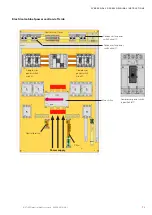

adjustment screws for setting threshold and pres-

sure hysteresis

delay (default setting: 120 sec., possibly raise on 300 sec.)

you can stepwise open the expansion valve in manual mode,

until you reach a suction pressure = thr 0,5 bar

(check by suction pressure gauge). If the LP switch still trips

after the elapsed evaluation delay and after having reached

the calculated suction pressure (1,6 bar), you must turn the

adjustment screw counterclockwise to reduce the pressure

hysteresis. One turn approximately corresponds to a hystere

-

sis change by 1,6 bar.