83

© STULZ GmbH – all rights reserved EN/09.2019/G41

cybercool 2 screw original insTrUcTions

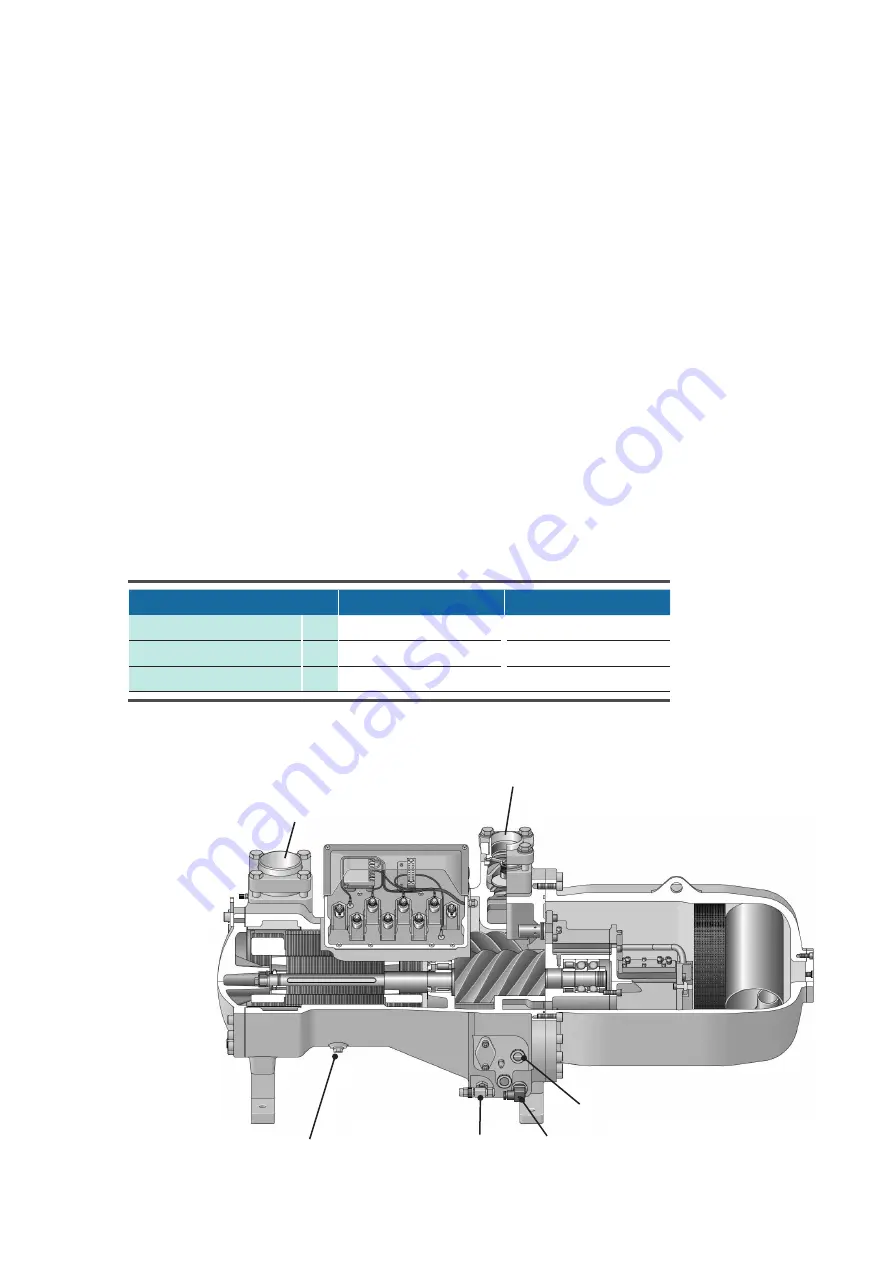

Screw compressor

In the screw compressor, there are three components which require inspection and maintenance. 1. the pres

-

sure relief valve, 2. the check valve, 3. the roller bearing. The integrated oil filter is maintenance-free.

1. Pressure relief valve

The pressure relief valve has a response pressure difference of 28 bar and is maintenance-free. Repeated

opening of the valve due to abnormal operating conditions, however, may result in steady leakage. This can be

detected by a reduced output and a high discharge gas temperature. If this the case, replace the valve.

2. Check valve

To protect the compressor against reverse rotation during standstill, a check valve is installed under the dis

-

charge shut-off valve resp. below the pipe connection. If the compressor runs in reverse direction for more

than aproximately 5 sec. after the cut-off, the valve may be defective and must be replaced. A reverse rotation

of the compressor can be detected by an abnormal sound.

3. Roller bearing

The screw compressors are equipped with fatigue endurable roller bearings. The bearings can be checked

by means of a sound analysis. If the bearings must be replaced, also the rotors, the housing and the discharge

flange should be checked visuallly. In case of severe scores or abnormal abrasion, a major overhaul of the

compressor or its replacement is advisable .

(2) oil service valve

(1) oil drain plug

(3) oil sight glass

oil heater

hot gas line connection

suction line connection

Screw compressor, sectional view

Component

Inspection intervall

Replacement intervall

Pressure relief valve

h

only if damage is suspected

100.000

Check valve

h

5.000*

20.000 ... 40.000

Roller bearing

h

10.000

50.000

*at least yearly check