86

EN/09.2019/G41 © STULZ GmbH – all rights reserved

cybercool 2 screw original insTrUcTions

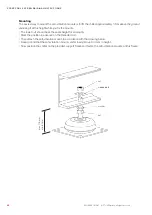

Removal of a condenser fan

WARnIng

Risk of injury by burns and rotation

The electronics housing can get hot.

The fans have an operation delay after the unit is stopped !

You need an appropriate secured access (e.g. working platform) to the chiller top, to dismount a condenser fan

for each heat exchanger element.

• open the centrally located cable duct on top of the chiller.

The duct is divided into a part for the power lines and a narrower part for control lines. The fan is connected by

a screwed plug connection in the power line part and two screwed plug connections in the control line part.

• disconnect the electrical connections and protect them against damage and humidity.

• completely unscrew the 4 Torx screws of the fan grille

• lift the fan (weight: approx. 30 kg) with another person and place it upside down on a fan next to it.

Condenser fan

The bearings of the fans are lifetime lubricated and do not need maintenance. Check the operation current.

An increased operation current indicates a winding short circuit in the fan motor.

Air filter in the compressor cabinet

• Check the filter in the air intake / outlet (see figure on page 21) in terms of pollution (visual inspection).

• Replace the filters (filter class G3) if necessary. The grilles are held by plastic clips and can be removed

using a screwdriver.

Top view

access by removing or tipping up condenser

fans

You must remove a condenser fan for each

heat exchanger element, if the chiller is not

equipped with movable fans (option).

nOTICE

The rebound of the high pressure

cleaner can damage the fins of

the opposite coil.