87

© STULZ GmbH – all rights reserved EN/09.2019/G41

cybercool 2 screw original insTrUcTions

Tightness

A lack of water in the circuit is replaced by air, which reduces the heat capacity of the chilled water circuit and

is detrimental to the pump. A level indication at the storage tank, if existant, can give information about chan-

ges of the water quantity.

• check the water circuit visually for tightness.

Evaporator

• Check the water side pollution of the tube evaporator by comparing the chilled water inlet temperature to

the chilled water outlet temperature at full load.

If the difference is less than 3 K, it indicates a limited heat transmission and thus pollution.

Another possibility to verify this, consists in the comparison of the chilled water outlet temperature with the

saturated evaporation temperature (by measuring the suction pressure at the low pressure side of the com

-

pressor). If this difference exceeds 7 K, the evaporator is probably polluted.

In this case the evaporator has to be cleaned chemically.

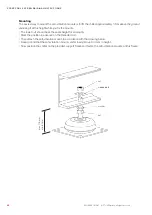

7.5 Water circuit

Frost protection sensor

Flow sensor

Water outlet temperature sensor

Water inlet temperature sensor

Chilled water sensors

Pump (option)

The pump is equipped with permanently lubricated bearings. According to the manufacturer's instructions,

the bearings have an expected durability of 20,000 operating hours.

• check the pump for audible and visible wearing.

• replace the bearings with noticeable wearing.

• for instructions on how to replace the bearing see QR-code on the pump or instruction sheet in the e Stulz

area.