90

ioc 01:>comp 1

Compressor 1

Configured..................:1

Type.......................:3 (CSW)

.

.

.

envelope zone (and state).........:6 (6)

eco...............................:0

Comp. prot. device................:0

envelope left.....................:1

Alarm.............................:0

Alarm low press...................:0

EN/09.2019/G41 © STULZ GmbH – all rights reserved

cybercool 2 screw original insTrUcTions

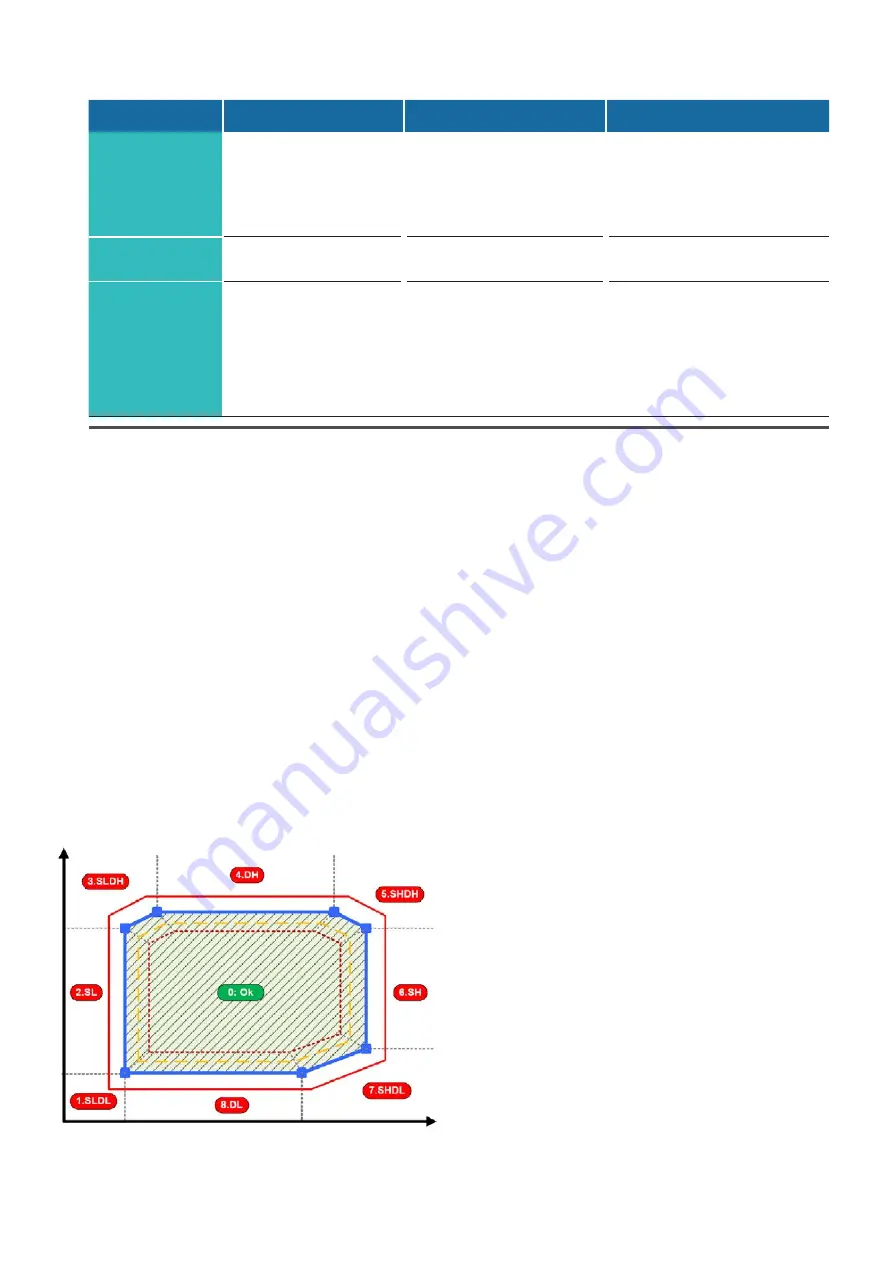

Example how to proceed in the event of the alarm "

envelope left C.1

"

Suction gas pressure

H

ot

gas

pr

essur

e

Envelope zones

:

0: Pressure conditions ok.

1: Suction pressure too low, Hot gas pressure too low

2: Suction pressure too low, Hot gas pressure ok

3:

Suction pressure too low, Hot gas pressure too high

4: Suction pressure ok, Hot gas pressure too high

5: Suction pressure too high, Hot gas pressure too high

6: Suction pressure too high, Hot gas pressure ok

7: Suction pressure too high, Hot gas pressure too low

8: Suction pressure ok, Hot gas pressure

too low

Envelope state

:

4: Warning (pressure ratio is located in the area

between yellow and blue line in the chart.)

5: Critical (pressure ratio is located in the area bet

-

ween blue and red line in the chart.)

6: Fault (pressure ratio is located out of the red line

or longer than 30 seconds between blue and red

line.)

Interpretation of the alarm display:

Envelope zone 6 and envelope state 6 testify that

the suction pressure is consistently too high.

Alarm message

Cause for alarm

Cause

Elimination

Comp. prot. device

#

Compressor protection device

has detected an anomaly.

1. Wrong sense of rotation.

2. Motor coil temperature too high

3. Hot gas temperature too high

4. Oil temperature too high

5. 3 phase failures in 18 min. or 10

phase failures in 24 hours.

Find the exact cause of error.

After elimination of error press the

release button in the electric cabinet

for 5 sec. at least.

Oelstand-Alarm #

Oil level sensor has detected

that the oil level is too low.

Oil shortage by low oil return at the

cold start or because of leakage.

Refill oil. Respect oil temperature con-

ditions at the compressor start.

envelope left C.#

The evaluation device of the

compressor or the C7000 con

-

troller has detected an anomaly.

The pressure application range

(condensation pressure and suction

pressure) of the compressor has

been left. Possible reasons may be:

a. Overcharge of refrigerant

b. Insufficient refrigerant charge

c. Excessive outdoor temperature.

d. Water inlet temp. is too high.

The error cause must be found in com

-

bination with other alarm messages.

# stands for a number in case of several components of the same kind.