31

© STULZ S.p.A. – all rights reserved EN/06.2016/i01

WPA ExPlOrEr OrIGINAl INSTrUCTIONS

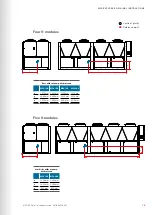

The WP

A 160 - 180 - 200 models

wer

e

only

available

in

configur

ation

1

FL,

R

A

, RE ar

e a

vailable as options.

FL is not a

vailable for WP

A 160 - 180 - 200 models

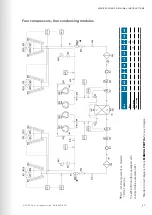

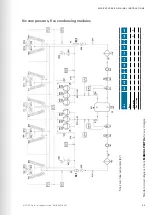

Standar

d cir

cuit diagr

am.

C

heck

MANU

Al

P

Ar

T

IIa

for any c

hange

s.

4.5.2 Standard & low Noise version