45

8.3 Helix test

The Helix test represents a hollow A-type load, i.e. the load with the most critical

characteristics.

Carry out the test as follows (Example of TST LOADCHEK STEAM):

Warning:

TST LOADCHEK STEAM

is trademark of ALBERT BROWNE LTD.,

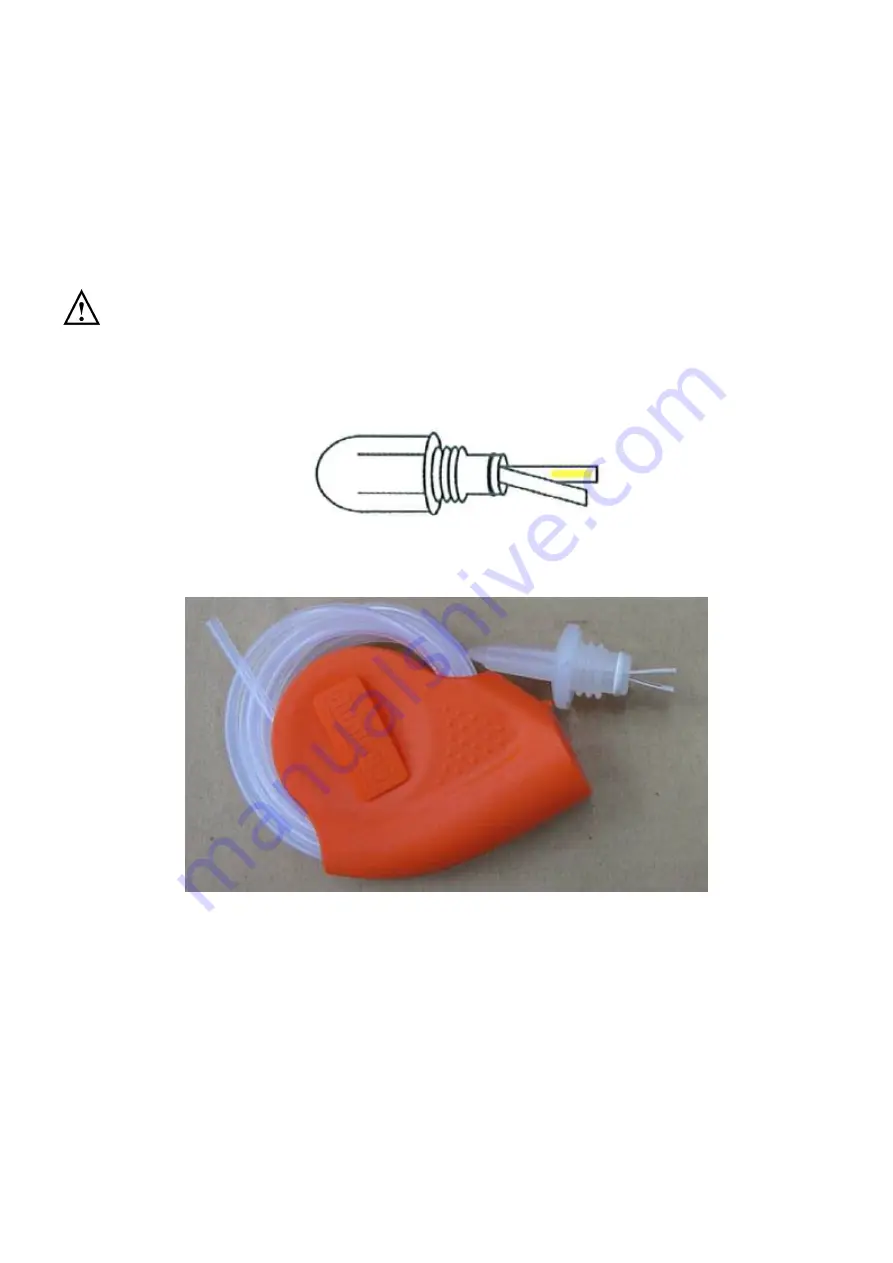

1. Place a test strip (Order code : 3783) inside the capsule.

Figure 46

Figure 47

2. Close the capsule.

3. Place the test kit on the lower tray in the chamber.

4. Select and start B&D cycle at control panel.

5. Once the cycle is completed, open the door and remove the test.