EX(H6DO)-4

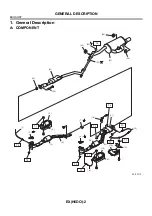

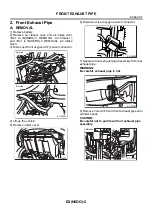

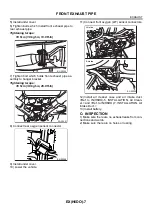

EXHAUST

GENERAL DESCRIPTION

B: CAUTION

• Wear working clothing, including a cap, protec-

tive goggles, and protective shoes during opera-

tion.

• Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

• Keep the disassembled parts in order and pro-

tect them from dust or dirt.

• Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly, and replacement.

• Be careful not to burn your hands, because each

part on the vehicle is hot after running.

• Be sure to tighten fasteners including bolts and

nuts to the specified torque.

• Place shop jacks or safety stands at the specified

points.

• Before disconnecting electrical connectors of

sensors or units, be sure to disconnect ground ca-

ble from battery.

Summary of Contents for 2003 Legacy

Page 3: ......

Page 4: ...FOREWORD FW Page 1 Foreword 2...

Page 6: ...HOW TO USE THIS MANUALS HU Page 1 How to Use This Manuals 2...

Page 11: ...HU 6 HOW TO USE THIS MANUALS HOW TO USE THIS MANUALS MEMO...

Page 12: ...SPECIFICATIONS SPC Page 1 Legacy 2 2 OUTBACK 10...

Page 26: ...PRECAUTION PC Page 1 Precaution 2...

Page 28: ...NOTE NT Page 1 Note 2...

Page 35: ...NT 8 NOTE NOTE MEMO...

Page 36: ...IDENTIFICATION ID Page 1 Identification 2...

Page 42: ...RECOMMENDED MATERIALS RM Page 1 Recommended Materials 2...

Page 47: ...RM 6 RECOMMENDED MATERIALS RECOMMENDED MATERIALS MEMO...

Page 48: ...PRE DELIVERY INSPECTION PI Page 1 Pre delivery Inspection 2...

Page 105: ...PM 46 PERIODIC MAINTENANCE SERVICES STEERING SYSTEM POWER STEERING MEMO...

Page 110: ...FU H4SO 3 FUEL INJECTION FUEL SYSTEMS GENERAL DESCRIPTION MEMO...

Page 181: ...FU H4SO 74 FUEL INJECTION FUEL SYSTEMS FUEL SYSTEM TROUBLE IN GENERAL MEMO...

Page 208: ...ME H4SO 11 MECHANICAL GENERAL DESCRIPTION MEMO...

Page 335: ...CO H4SO 34 COOLING ENGINE COOLING SYSTEM TROUBLE IN GENERAL MEMO...

Page 355: ...LU H4SO 20 LUBRICATION ENGINE LUBRICATION SYSTEM TROUBLE IN GENERAL MEMO...

Page 397: ...SC H4SO 22 STARTING CHARGING SYSTEMS BATTERY MEMO...

Page 406: ...EN H4SO 9 ENGINE DIAGNOSTICS GENERAL DESCRIPTION MEMO...

Page 420: ...EN H4SO 23 ENGINE DIAGNOSTICS ELECTRICAL COMPONENTS LOCATION MEMO...

Page 452: ...EN H4SO 55 ENGINE DIAGNOSTICS ENGINE MALFUNCTION INDICATOR LAMP MI MEMO...

Page 460: ...EN H4SO 63 ENGINE DIAGNOSTICS DIAGNOSTICS FOR ENGINE STARTING FAILURE MEMO...

Page 464: ...EN H4SO 67 ENGINE DIAGNOSTICS DIAGNOSTICS FOR ENGINE STARTING FAILURE MEMO...

Page 468: ...EN H4SO 71 ENGINE DIAGNOSTICS DIAGNOSTICS FOR ENGINE STARTING FAILURE MEMO...

Page 472: ...EN H4SO 75 ENGINE DIAGNOSTICS DIAGNOSTICS FOR ENGINE STARTING FAILURE MEMO...

Page 476: ...EN H4SO 79 ENGINE DIAGNOSTICS DIAGNOSTICS FOR ENGINE STARTING FAILURE MEMO...

Page 492: ...EN H4SO 95 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 498: ...EN H4SO 101 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 506: ...EN H4SO 109 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 510: ...EN H4SO 113 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 518: ...EN H4SO 121 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 524: ...EN H4SO 127 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 530: ...EN H4SO 133 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 536: ...EN H4SO 139 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 540: ...EN H4SO 143 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 552: ...EN H4SO 155 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 556: ...EN H4SO 159 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 560: ...EN H4SO 163 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 586: ...EN H4SO 189 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 590: ...EN H4SO 193 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 596: ...EN H4SO 199 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 600: ...EN H4SO 203 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 606: ...EN H4SO 209 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 610: ...EN H4SO 213 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 616: ...EN H4SO 219 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 618: ...EN H4SO 221 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 622: ...EN H4SO 225 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 642: ...EN H4SO 245 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 646: ...EN H4SO 249 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 648: ...EN H4SO 251 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 658: ...EN H4SO 261 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 662: ...EN H4SO 265 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 682: ...EN H4SO 285 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 690: ...EN H4SO 293 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 703: ...EN H4SO 306 ENGINE DIAGNOSTICS GENERAL DIAGNOSTIC TABLE MEMO...

Page 706: ...FU H4SOw oOBD 3 FUEL INJECTION FUEL SYSTEMS GENERAL DESCRIPTION MEMO...

Page 783: ...EC H4SOw oOBD 10 EMISSION CONTROL AUX EMISSION CONTROL DEVICES TWO WAY VALVE MEMO...

Page 784: ...INTAKE INDUCTION IN H4SOw oOBD Page 1 General Description 2...

Page 786: ...MECHANICAL ME H4SOw oOBD Page 1 General Description 2...

Page 802: ...COOLING CO H4SOw oOBD Page 1 General Description 2...

Page 804: ...LUBRICATION LU H4SOw oOBD Page 1 General Description 2...

Page 806: ...SPEED CONTROL SYSTEMS SP H4SOw oOBD Page 1 General Description 2...

Page 818: ...STARTING CHARGING SYSTEMS SC H4SOw oOBD Page 1 General Description 2...

Page 925: ......

Page 928: ...FU H6DO 3 FUEL INJECTION FUEL SYSTEMS GENERAL DESCRIPTION MEMO...

Page 934: ...FU H6DO 9 FUEL INJECTION FUEL SYSTEMS GENERAL DESCRIPTION MEMO...

Page 1101: ...ME H6DO 80 MECHANICAL ENGINE NOISE MEMO...

Page 1111: ...EX H6DO 10 EXHAUST MUFFLER MEMO...

Page 1149: ...CO H6DO 38 COOLING ENGINE COOLING SYSTEM TROUBLE IN GENERAL MEMO...

Page 1152: ...LU H6DO 3 LUBRICATION GENERAL DESCRIPTION MEMO...

Page 1185: ...IG H6DO 8 IGNITION IGNITION COIL AND IGNITOR ASSEMBLY MEMO...

Page 1207: ...SC H6DO 22 STARTING CHARGING SYSTEMS BATTERY MEMO...

Page 1228: ...EN H6DO 21 ENGINE DIAGNOSTICS ELECTRICAL COMPONENTS LOCATION EN 00922 1 EN 01262 2...

Page 1264: ...EN H6DO 57 ENGINE DIAGNOSTICS COMPULSORY VALVE OPERATION CHECK MODE MEMO...

Page 1270: ...EN H6DO 63 ENGINE DIAGNOSTICS ENGINE MALFUNCTION INDICATOR LAMP MI MEMO...

Page 1277: ...EN H6DO 70 ENGINE DIAGNOSTICS ENGINE MALFUNCTION INDICATOR LAMP MI MEMO...

Page 1282: ...EN H6DO 75 ENGINE DIAGNOSTICS DIAGNOSTICS FOR ENGINE STARTING FAILURE MEMO...

Page 1286: ...EN H6DO 79 ENGINE DIAGNOSTICS DIAGNOSTICS FOR ENGINE STARTING FAILURE MEMO...

Page 1290: ...EN H6DO 83 ENGINE DIAGNOSTICS DIAGNOSTICS FOR ENGINE STARTING FAILURE MEMO...

Page 1302: ...EN H6DO 95 ENGINE DIAGNOSTICS LIST OF DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1306: ...EN H6DO 99 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1314: ...EN H6DO 107 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1318: ...EN H6DO 111 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1330: ...EN H6DO 123 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1336: ...EN H6DO 129 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1348: ...EN H6DO 141 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1354: ...EN H6DO 147 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1360: ...EN H6DO 153 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1366: ...EN H6DO 159 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1372: ...EN H6DO 165 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1380: ...EN H6DO 173 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1386: ...EN H6DO 179 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1390: ...EN H6DO 183 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1402: ...EN H6DO 195 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1408: ...EN H6DO 201 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1436: ...EN H6DO 229 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1442: ...EN H6DO 235 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1450: ...EN H6DO 243 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1454: ...EN H6DO 247 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1472: ...EN H6DO 265 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1484: ...EN H6DO 277 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1494: ...EN H6DO 287 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1506: ...EN H6DO 299 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1528: ...EN H6DO 321 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1541: ...EN H6DO 334 ENGINE DIAGNOSTICS GENERAL DIAGNOSTIC TABLE MEMO...

Page 1543: ......

Page 1546: ...FU H4DOSTC 3 FUEL INJECTION FUEL SYSTEMS GENERAL DESCRIPTION MEMO...

Page 1621: ...EC H4DOSTC 8 EMISSION CONTROL AUX EMISSION CONTROL DEVICES TWO WAY VALVE MEMO...

Page 1626: ...IN H4DOSTC 5 INTAKE INDUCTION GENERAL DESCRIPTION MEMO...

Page 1645: ...IN H4DOSTC 24 INTAKE INDUCTION DIFFERENTIAL PRESSURE SENSOR MEMO...

Page 1654: ...ME H4DOSTC 9 MECHANICAL GENERAL DESCRIPTION MEMO...

Page 1741: ...ME H4DOSTC 96 MECHANICAL ENGINE NOISE MEMO...

Page 1812: ...SPEED CONTROL SYSTEMS SP H4DOSTC Page 1 General Description 2...

Page 1882: ...EN H4DOSTC 43 ENGINE DIAGNOSTICS ENGINE MALFUNCTION INDICATOR LAMP MI MEMO...

Page 1884: ...EN H4DOSTC 45 ENGINE DIAGNOSTICS ENGINE MALFUNCTION INDICATOR LAMP MI MEMO...

Page 1889: ...EN H4DOSTC 50 ENGINE DIAGNOSTICS ENGINE MALFUNCTION INDICATOR LAMP MI MEMO...

Page 1894: ...EN H4DOSTC 55 ENGINE DIAGNOSTICS DIAGNOSTICS FOR ENGINE STARTING FAILURE MEMO...

Page 1898: ...EN H4DOSTC 59 ENGINE DIAGNOSTICS DIAGNOSTICS FOR ENGINE STARTING FAILURE MEMO...

Page 1908: ...EN H4DOSTC 69 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1914: ...EN H4DOSTC 75 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1920: ...EN H4DOSTC 81 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1926: ...EN H4DOSTC 87 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1930: ...EN H4DOSTC 91 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1936: ...EN H4DOSTC 97 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1942: ...EN H4DOSTC 103 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1946: ...EN H4DOSTC 107 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1952: ...EN H4DOSTC 113 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1956: ...EN H4DOSTC 117 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1960: ...EN H4DOSTC 121 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1966: ...EN H4DOSTC 127 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1970: ...EN H4DOSTC 131 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1974: ...EN H4DOSTC 135 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1986: ...EN H4DOSTC 147 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1990: ...EN H4DOSTC 151 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 1994: ...EN H4DOSTC 155 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 2000: ...EN H4DOSTC 161 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 2016: ...EN H4DOSTC 177 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 2022: ...EN H4DOSTC 183 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 2028: ...EN H4DOSTC 189 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 2036: ...EN H4DOSTC 197 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 2040: ...EN H4DOSTC 201 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 2046: ...EN H4DOSTC 207 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 2052: ...EN H4DOSTC 213 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 2062: ...EN H4DOSTC 223 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 2068: ...EN H4DOSTC 229 ENGINE DIAGNOSTICS DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 2087: ...EN H4DOSTC 248 ENGINE DIAGNOSTICS GENERAL DIAGNOSTIC TABLE MEMO...

Page 2089: ......

Page 2115: ...CS 26 CONTROL SYSTEMS GENERAL DIAGNOSTIC TABLE MEMO...

Page 2308: ...AT 33 AUTOMATIC TRANSMISSION DIAGNOSTICS DIAGNOSTIC PROCEDURE FOR POWER INDICATOR LIGHT MEMO...

Page 2312: ...AT 37 AUTOMATIC TRANSMISSION DIAGNOSTICS DIAGNOSTIC PROCEDURE FOR POWER INDICATOR LIGHT MEMO...

Page 2441: ...AT 166 AUTOMATIC TRANSMISSION DIAGNOSTICS SYMPTOM RELATED DIAGNOSTIC MEMO...

Page 2450: ...MT 9 MANUAL TRANSMISSION AND DIFFERENTIAL GENERAL DESCRIPTION MEMO...

Page 2597: ......

Page 2717: ...DI 62 DIFFERENTIALS GENERAL DIAGNOSTIC TABLE MEMO...

Page 2818: ...ABS 27 ABS DIAGNOSTICS LIST OF DIAGNOSTICS TROUBLE CODE DTC MEMO...

Page 2822: ...ABS 31 ABS DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 2826: ...ABS 35 ABS DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 2830: ...ABS 39 ABS DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 2836: ...ABS 45 ABS DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 2846: ...ABS 55 ABS DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 2850: ...ABS 59 ABS DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 2860: ...ABS 69 ABS DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 2878: ...ABS 87 ABS DIAGNOSTICS DIAGNOSTICS CHART WITH SUBARU SELECT MONITOR MEMO...

Page 2890: ...ABS 99 ABS DIAGNOSTICS DIAGNOSTICS CHART WITH SUBARU SELECT MONITOR MEMO...

Page 2896: ...ABS 105 ABS DIAGNOSTICS DIAGNOSTICS CHART WITH SUBARU SELECT MONITOR MEMO...

Page 2900: ...ABS 109 ABS DIAGNOSTICS DIAGNOSTICS CHART WITH SUBARU SELECT MONITOR MEMO...

Page 2928: ...ABS 137 ABS DIAGNOSTICS DIAGNOSTICS CHART WITH SUBARU SELECT MONITOR MEMO...

Page 2936: ...ABS 145 ABS DIAGNOSTICS DIAGNOSTICS CHART WITH SUBARU SELECT MONITOR MEMO...

Page 2941: ...ABS 150 ABS DIAGNOSTICS GENERAL DIAGNOSTICS TABLE MEMO...

Page 3028: ...VDC 55 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 3042: ...VDC 69 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 3062: ...VDC 89 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 3066: ...VDC 93 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 3070: ...VDC 97 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 3086: ...VDC 113 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 3090: ...VDC 117 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 3098: ...VDC 125 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH DIAGNOSIS CONNECTOR MEMO...

Page 3118: ...VDC 145 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3128: ...VDC 155 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3140: ...VDC 167 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3144: ...VDC 171 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3148: ...VDC 175 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3154: ...VDC 181 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3158: ...VDC 185 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3162: ...VDC 189 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3166: ...VDC 193 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3172: ...VDC 199 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3186: ...VDC 213 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3190: ...VDC 217 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3196: ...VDC 223 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3200: ...VDC 227 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3210: ...VDC 237 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3214: ...VDC 241 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3218: ...VDC 245 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3222: ...VDC 249 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3228: ...VDC 255 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3238: ...VDC 265 VDC DIAGNOSTICS DIAGNOSTICS CHART WITH SELECT MONITOR MEMO...

Page 3251: ...VDC 278 VDC DIAGNOSTICS GENERAL DIAGNOSTIC TABLE MEMO...

Page 3328: ...PS 7 POWER ASSISTED SYSTEM POWER STEERING GENERAL DESCRIPTION MEMO...

Page 3482: ...AC 9 HVAC SYSTEM AUTO A C DIAGNOSTICS ELECTRICAL COMPONENTS LOCATION MEMO...

Page 3490: ...AC 17 HVAC SYSTEM AUTO A C DIAGNOSTICS SELF DIAGNOSIS PROCEDURE LHD MODEL MEMO...

Page 3510: ...AC 37 HVAC SYSTEM AUTO A C DIAGNOSTICS DIAGNOSTICS FOR A C SYSTEM FAILURE RHD MODEL MEMO...

Page 3553: ...AC 80 HVAC SYSTEM AUTO A C DIAGNOSTICS SYMPTOM RELATED DIAGNOSTIC MEMO...

Page 3606: ...AB 23 AIRBAG SYSTEM DIAGNOSTICS CLEAR MEMORY MODE MEMO...

Page 3616: ...AB 33 AIRBAG SYSTEM DIAGNOSTICS DIAGNOSTIC CHART WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 3626: ...AB 43 AIRBAG SYSTEM DIAGNOSTICS DIAGNOSTIC CHART WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 3652: ...AB 69 AIRBAG SYSTEM DIAGNOSTICS DIAGNOSTIC CHART WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 3661: ...AB 78 AIRBAG SYSTEM DIAGNOSTICS DIAGNOSTIC CHART WITH DIAGNOSTIC TROUBLE CODE DTC MEMO...

Page 3744: ...COMMUNICATION SYSTEM COM Page 1 General Description 2 2 Horn System 3 3 Horn 4 4 Horn Switch 5...

Page 3749: ...COM 6 COMMUNICATION SYSTEM HORN SWITCH MEMO...

Page 3789: ...GW 40 GLASS WINDOWS MIRRORS WIPER DEICER SWITCH MEMO...

Page 3790: ...BODY STRUCTURE BS Page 1 General Description 2 2 Datum Points 3 3 Datum Dimensions 10...

Page 3802: ...BS 13 BODY STRUCTURE DATUM DIMENSIONS MEMO...

Page 3806: ...BS 17 BODY STRUCTURE DATUM DIMENSIONS MEMO...

Page 3809: ...BS 20 BODY STRUCTURE DATUM DIMENSIONS MEMO...

Page 3832: ...SEATS SE Page 1 General Description 2 2 Front Seat 7 3 Rear Seat 17...

Page 3853: ...SE 22 SEATS REAR SEAT MEMO...

Page 3893: ...SL 40 SECURITY AND LOCKS KEYLESS TRANSMITTER MEMO...

Page 3977: ...EB 20 EXTERIOR BODY PANELS REAR GATE PANEL MEMO...

Page 3989: ...CC 12 CRUISE CONTROL SYSTEM INHIBITOR SWITCH...

Page 4055: ......

Page 4070: ...WI 15 WIRING SYSTEM SUPER MULTIPLE JUNCTION SMJ MEMO...

Page 4116: ...WI 61 WIRING SYSTEM AIRBAG SYSTEM MEMO...

Page 4146: ...WI 91 WIRING SYSTEM ANTI LOCK BRAKE SYSTEM MEMO...

Page 4172: ...WI 117 WIRING SYSTEM A T CONTROL SYSTEM MEMO...

Page 4196: ...WI 141 WIRING SYSTEM COMBINATION METER MEMO...

Page 4212: ...WI 157 WIRING SYSTEM CRUISE CONTROL SYSTEM MEMO...

Page 4282: ...WI 227 WIRING SYSTEM ENGINE ELECTRICAL SYSTEM MEMO...

Page 4286: ...WI 231 WIRING SYSTEM FUEL GAUGE SYSTEM MEMO...

Page 4318: ...WI 263 WIRING SYSTEM FRONT FOG LIGHT SYSTEM MEMO...

Page 4352: ...WI 297 WIRING SYSTEM REAR WINDOW DEFOGGER SYSTEM MEMO...

Page 4362: ...WI 307 WIRING SYSTEM SUNROOF SYSTEM MEMO...

Page 4384: ...WI 329 WIRING SYSTEM WIPER DEICER SYSTEM MEMO...

Page 4441: ...WI 386 WIRING SYSTEM REAR WIRING HARNESS AND REAR GATE CORD MEMO...