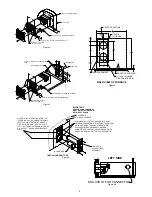

POWER SUPPLY & THERMOSTAT WIRES

GAS INLET FOR ELECTRIC IGNITION MODELS

SECURE UNIT IN PLACE

WITH (2) SCREWS

1 3/8"

10 3/16"

10 9/16"

BACK OF FURNACE CABINET

9 3/8"

TRAILER SKIN

9 5/8"

2 1/2" MAX.

Figure 2

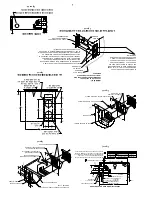

POWER SUPPLY & THERMOSTAT WIRES

GAS INLET FOR ELECTRIC IGNITION MODELS

SECURE UNIT IN PLACE

WITH (2) SCREWS

TRAILER SKIN

7 1/2"

3 1/2"

3 15/16"

2"

4"

2 1/4" DIA. TWO HOLES THROUGH TRAILER

SKIN

MOUNTING SURFACE

INSIDE WALL

1 3/8"

10 3/16"

10 9/16"

2"

Figure 3

FURNACE CABINET

2 1/4 DIA. (2) HOLES

THRU TRAILOR SKIN

MOUNTING SURFACE

7/64 DIA.

(4) HOLES

VENT CAP OUTLINE

9 5

16

2 3

16

134

6

1 16

9

5 16

1 4

315 16

31 2

1

9 32

212

BACK VIEW OF FURNACE

Figure 4

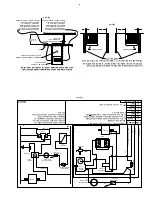

INSTALLING VENT CAP

IMPORTANT:

VENT CAP AND TUBE ASSY.

MUST BE INSTALLED FROM

OUTSIDE OF COACH.

TRAILER SKIN

OUTLINE OF FURNACE

VENT CAP &

EXHAUST TUBE

ASSEMBLY

HOLE DIA. IN OUTER SKIN MAY BE 2 1/4"

IF OPENING CUT IN COMBUSTIBLE WALL

IS CUT AS ILLUSTRATED IN FIGURES 3

OR 4. HOLE DIA. MUST BE 2 3/4" IF THE

4 X 7 1/2" OPENING AS SHOWN IN FIGURE

4 IS NOT CUT THROUGH COMBUSTIBLE

WALL.

INTAKE TUBE

CAULK BEHIND VENT CAP AS SHOWN TO SEAL

BETWEEN EXHAUST AND INTAKE AND TO PREVENT

MOISTURE INSIDE FURNACE COMPARTMENT.

APPLY CAULKING GENEROUSLY AROUND

PERIMETER OF VENT CAP AND ACROSS CENTER

AS SHOWN. CENTER PUTTY STRIP IS ESSENTIAL.

Figure 6

LEFT SIDE

KNOCKOUT FOR CONNECTOR

Figure 6A

3