Page 8

Wine Storage

Wine Storage

(400-

(400-

2

2

)

)

Series

Series

Installation Information

2-3

#3758410 - Revision C - May, 2014

Sub-Zero Unit

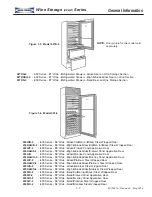

Figure 2-3. Anti-Tip Components

Wall Stud

Wood Block

Screws &

L-Bracket

Min. 3”

(76.2 mm)

Anti-Tip Components Installation (430-2)

If anti-tip components (aka wood block / blocking kit)

need be installed, follow these steps (See Figure 2-3):

1. Locate and mark two wall studs at back of unit

installation location.

2. Identify and mark proper height to clear unit top.

Space between unit top and bottom of wood block

must NOT be more then 1/4" (6.1 mm).

3. Using the L-brackets and screws provided, secure

wood block to wall studs, located in step 1, making

sure screws extend 7/8" (22.2 mm) into each wall

stud. The wood block must extend a minimum of 3"

(76.2 mm) over unit.

4. Utilizing front and rear levelers, raise and level unit

until it contacts wood block (See leveling instructions

on following pages).

5. Refer to Installation Guide provided with the unit for

any additional information needed.

Unit Leveling (424-2, 424FS-2)

NOTE:

Model 424-2 must be leveled before installing

into rough-in opening. If unit is already installed and

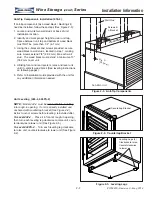

anchored with countertop bracket (See Figure 2-4),

Extract anchor screws before leveling, reinstalled after.

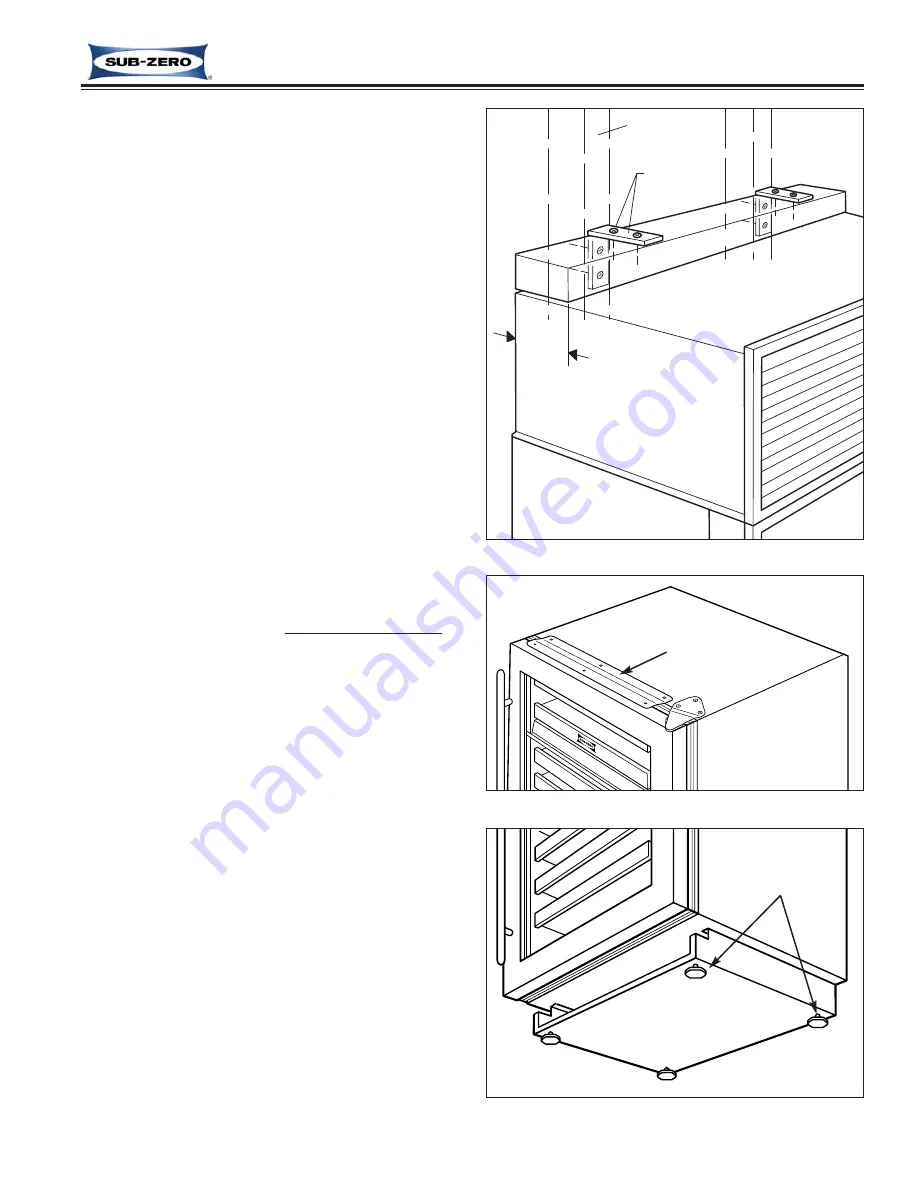

To Level 424-2

- Place it in front of rough-in opening,

then turn each leveling leg clockwise to raise unit, coun-

terclockwise to lower unit (See Figure 2-5).

To Level 424FS-2

- Turn each leveling leg clockwise

to raise unit, counterclockwise to lower unit (See Figure

2-2).

Figure 2-5. Leveling Legs

Figure 2-4. Countertop Bracket

Leveling Legs (4)

Clockwise to raise,

Counterclockwise

to lower

Countertop Bracket