2

No.

①

②

③

④

⑤

Name

Upper track

for soft-closing

(surface mount)

Upper track

for soft-closing

(recessed mount)

Upper track for

standard sliding

(surface mount)

Upper track for

standard sliding

(recessed mount)

Soft closer

(two-way)

Trigger, Jig

Upper roller

Item No.

FD35EV-TRM-SC FD35EV-TRH-SC

FD35EV-TRM

FD35EV-TRH

FD35EV-WRH-DSC

FD35EV-TRG

FD35EV-TRJ

FD35EV-WRH-N

Item

Flat head tapping screw

3.8×40

・・・・・・・

3 pcs

Countersunk head tapping screw

4×30

・・・・・・・・・

2 pcs

Flat head tapping screw

3.8×40

・・・・・・・

3 pcs

Accessories

Hole pitch

:

300 mm

Pitch end

:

30 mm

Recommended screw:Countersunk head tapping screw 3.5×25

Use the track for standard sliding for inline sliding

Hole pitch

:

300 mm

Pitch end

:

30 mm

Recommended screw:Countersunk head tapping screw 3.5×25

Single sliding

either one

−

1 pc

1 pc

1 pc

Double sliding

either one

−

2 pcs

2 pcs

2 pcs

In line sliding

−

either one

2 pcs

2 pcs

2 pcs

No.

⑥

⑦

⑧

⑨

⑩

⑪

⑫

Name

Floor guide

Bumper block

Trigger

Door guide track

Cover cap

Door stopper

Spanner

wrench

Item No.

FD50-BGR18

FD35EV-HBB

FD35EV-TRG

FD30-HBRT1500SIL

FD50-WRH-CP

FD30-HTKY

FD30-FSP

Item

Thickness: 2 mm

Bind head tapping screw

4×30

・・・・・・・・・

3 pcs

Hole pitch

:

250 mm

Pitch end

:

30 mm

Recommended screw:

Countersunk head tapping screw 4×20

Countersunk head tapping screw

4×20

・・・・・・・・・・・・・・・・・・

4 pcs

Single sliding

1 pc

−

−

1 pc

2 pcs

−

−

Double sliding

2 pcs

−

−

2 pcs

4 pcs

−

−

In line sliding

2 pcs

1 pc

2 pcs

2 pcs

4 pcs

−

−

Trigger

Nut

Trigger

Trigger

Jig

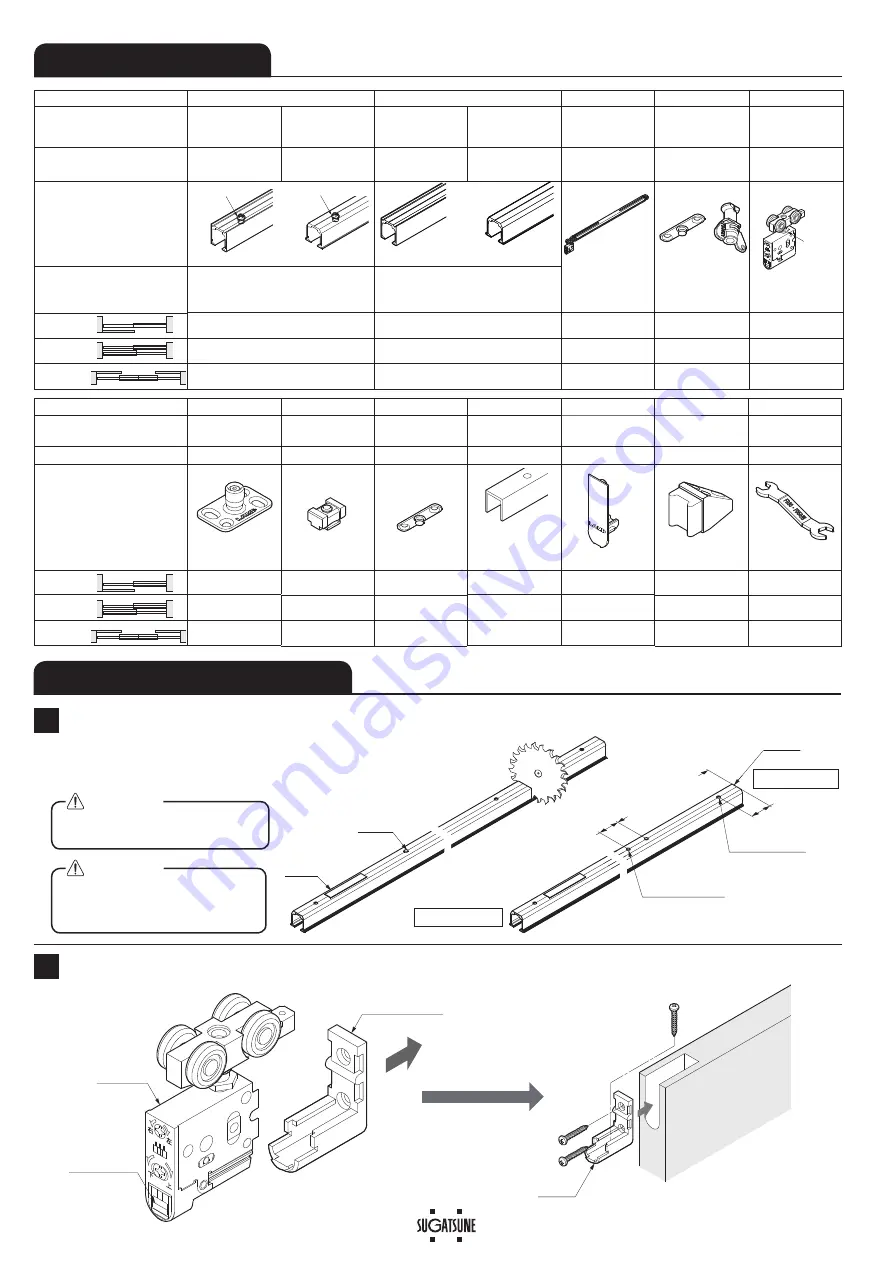

COMPONENT PARTS

This describes installation of a single sliding door.

INSTALLATION PROCEDURE

1

Cutting Track and Hole Drilling on Upper track

The method of calculating the trigger mounting

position is described on the last page of Appendix 4.

(

In this manual, a single sliding door is used as an example.

)

Preparation of Mounting Parts

2

Do not cut trigger side (with sticker)

of upper track.

When cutting, reinforce the track

to prevent deformation at the cut

section.

CAUTION

CAUTION

Casing

Hole drilling

Cutting

Sticker

Trigger

Cut end

2×

I

4.5

(for trigger fixing)

※

2

[ ]: When Cover cap

⑩

(option) is used.

I

4.5

I

7.8 CSK

(for track fixing)

30

Door width - 376

[Door width - 378 ]

※

2

30

Leading edge

Trailing edge

❶

❷

Main unit

Pull out casing

Pull up lever