2.2.3 Connecting/Detaching on flexible shaft

Press the locking button, and insert the hose coupling

into the handpiece hole. Make sure that the locking button

is engaged. Disassembly must be carried out in reverse

order.

2.3 AH 12 external receiver

The AH 12 external receiver is available as an accessory

and serves to enable the tool to be operated using both

hands.

2.3.1 Connecting/detaching the tool

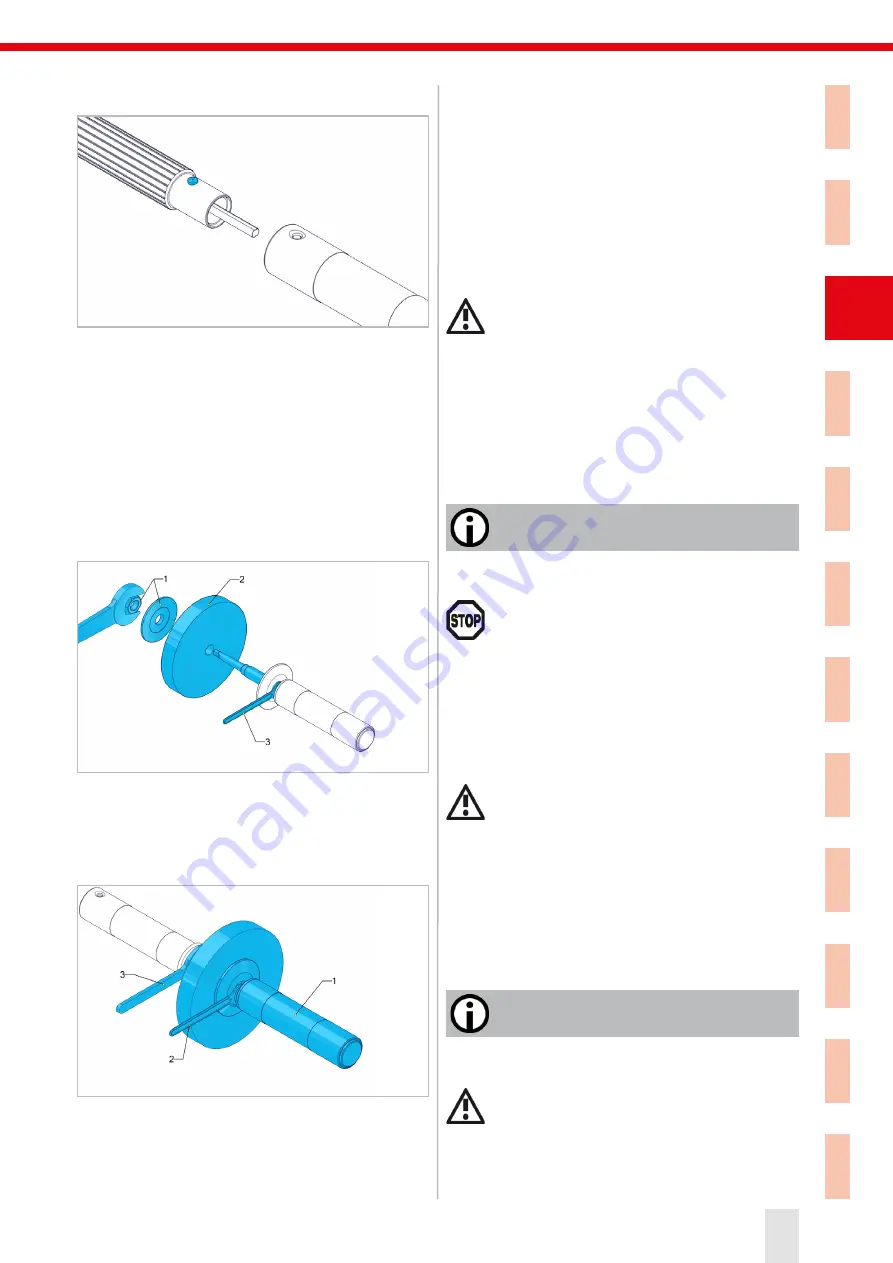

Loosen the nut and remove it with the pressure disc (1).

Fit the tool (2), refit the pressure disc, lock the spindle with

the spanner (3), tighten the nut (1).

2.3.2 Connecting/Detaching the external receiver

Insert the external receiver into the receiving hole on the

handpiece until it hits the limit stop (1). Lock the spin-

dle with the single open-ended spanner (2). Tighten the

threaded nut on the handpiece using the hook spanner

(3). Disassembly must be carried out in reverse order.

Fit handpiece on flexible shaft (see 2.2.3).

2.4 Rating data

Connection G35

Maximum speed Input

10’000min

-1

Max wheel diameter

175mm

Spindle MK1

Vibration EN 60745

6.2m/s

2

, K=1.5m/s

2

Weight WH 12

1.130kg

Weight AH 12

1.780kg

The specified vibration value was measured with a

standardised test method and may differ from the

actual operating value. The specified value can be

used for product comparisons or for an introductory as-

sessment of work breaks.

2.5 Operating conditions

Temperature range during operation: 0 to +50°C

Relative air humidity: 95% at +10°C not condensed

3.

haNDLINg

/ o

PERaTIoN

3.1 Working instructions

Do not leave the tool running without a machine!

To achieve an optimum grinding result, move

grinding tool uniformly back and forth with light

pressure.

Excessive pressure lessens the working capability of the

hand tool, as well as the life of the grinding tool.

3.2 Switching ON/OFF

Hold the hand tool firmly. Switch on the drive.

Conduct the test run without load for at least thirty

seconds. Do not use vibrating grinding tools.

You must always hold the hand tool when it is op-

erating.

Switch off the drive when you stop working.

The tool still needs time to stop after the tool has been

switched off.

Put down the hand tool so that there can be no danger.

Remove the hand tool from the shaft.

4. S

ERvICE

/ m

aINTENaNCE

4.1 Preventive maintenance

Always keep the hand tool clean and in a dry

place.

Worn mandrels must be replaced.

4.2 Repair

If despite strict observance of the manufacturing and test-

21

Summary of Contents for AH 12

Page 2: ...2 ...

Page 3: ...3 ...

Page 15: ...CN PL CZ FI SE NL PT ES IT EN FR DE 15 ...

Page 19: ...CN PL CZ FI SE NL PT ES IT EN DE FR 19 ...

Page 23: ...CN PL CZ FI SE NL PT ES IT FR DE EN 23 ...

Page 27: ...CN PL CZ FI SE NL PT ES EN FR DE IT 27 ...

Page 31: ...CN PL CZ FI SE NL PT IT EN FR DE ES 31 ...

Page 35: ...CN PL CZ FI SE NL ES IT EN FR DE PT 35 ...

Page 39: ...CN PL CZ FI SE PT ES IT EN FR DE NL 39 ...

Page 43: ...CN PL CZ FI NL PT ES IT EN FR DE SE 43 ...

Page 47: ...CN PL CZ SE NL PT ES IT EN FR DE FI 47 ...

Page 51: ...CN PL FI SE NL PT ES IT EN FR DE CZ 51 ...

Page 55: ...CN CZ FI SE NL PT ES IT EN FR DE PL 55 ...

Page 58: ...PL CZ FI SE NL PT ES IT EN FR DE CN 58 ...