No-load speed

2800-5900 min

-1

Max. tool Ø

55mm

Pince de serrage Ø max.

12mm / 1/2“

Sound pressure level EN 60745

86dB(A), K=3dB

Noise emission level

97dB(A), K=3dB

Vibration EN 60745

5.3m/s

2

, K=1.5m/s

2

Weight w/o cable

2.9kg

Protection class

II

The specified vibration value was measured with a

standardised test procedure. It can be used to

compare products or to make an initial assess-

ment of the exposure.

The vibration emissions may differ from the speci-

fied value,

depending on how the power tool is

used.

Operating personnel must be protected with de-

fined safety measures based on the estimated ex-

posure under the actual conditions of use

(these

must take into account all phases of the operat-

ing cycle, e.g. the times when the power tool is

switched OFF and the times it is switched ON, but

is not under load).

2.4 o

perAting

conDitions

Temperature range during operation: 0 to +50°C

Relative air humidity: 95 % at +10°C not condensed

3.

handling

/ o

peration

3.1 p

rotection

Divices

3.1.1 p

rotection

of

persons

• Fit safety guard

• ON/OFF switch

Two-pole ON/OFF switch with turn-on inhibitor and lock.

3.1.2 p

rotection

of

the

mAchine

s

tArting

current

limitAtion

The electronically controlled soft starting provides for jerk-

free starting of the machine. Due to the low machine start-

ing current a 16 A fuse is adequate.

t

emperAture

-

dependent

overloAd

protection

For protection against overheating, when a critical tem-

perature is reached the electronic safety feature switches

into the cool-down mode. The machine then continues

to run at a speed of approx: 1,100 rpm and the electronic

constant speed control is deactivated.

After a cool-down time of approx. 10 - 20 s the machine is

again ready for operation. Turn the machine off and back

on again to activate the electronic constant speed control.

With the tool at operating temperature the temperature-

dependent overload protection reacts correspondingly

earlier.

u

ndervoltAge

/ r

estArting

protection

On short-time failure of the power voltage (plug discon-

nected, instable power mains etc.) the machine will stop.

When the power voltage recovers, the machine must be

turned OFF and back ON again. Then the machine is

ready for operation.

3.2 r

otAtion

of

geArBox

heAD

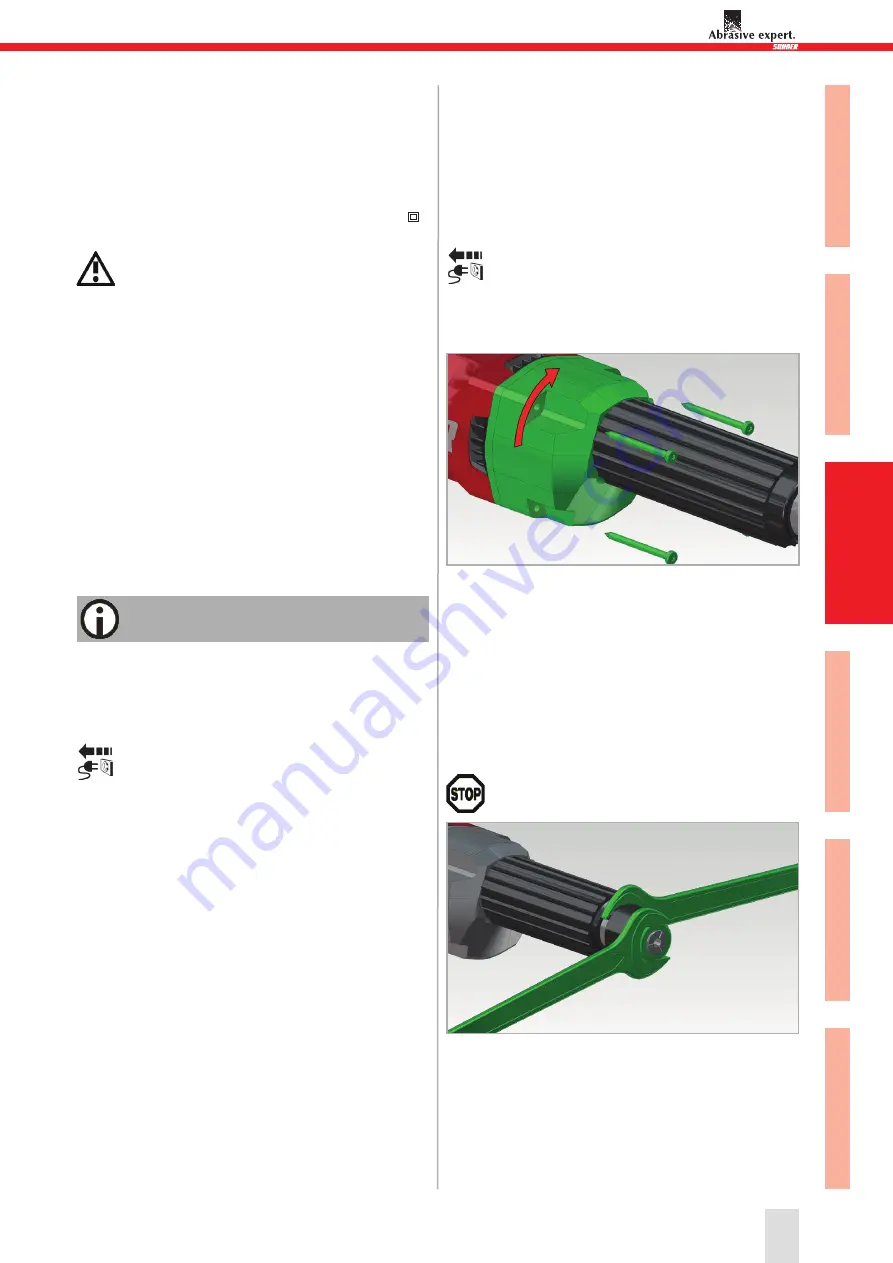

The gearbox head can be rotated relative to the

stator housing in steps of 90° which enables the

turn-on/turn-off switch to be brought into a more

convenient manipulation position for special work

situations.

Completely unscrew the four screws. Carefully and with-

out removing the housing rotate the tool head into a new

position. Screw screws back in and tighten down.

3.3 g

rinDing

tool

Use only grinding tools whose admissible maximum

speed is equal to or higher than the no-load speed of the

machine.

3.3.1 c

hAnging

/

fitting

the

grinDing

tool

Use only clean tools!

Hold spindle against turning at wrench flats with open-

end wrench WS 22. Release the clamping nut with an

open end wrench WS 22.

17

P

ortugúes

Espnõl

Italiano

F

rançais

Deutsch

English