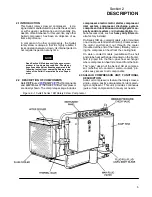

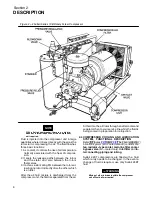

Section 2

DESCRIPTION

8

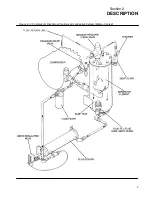

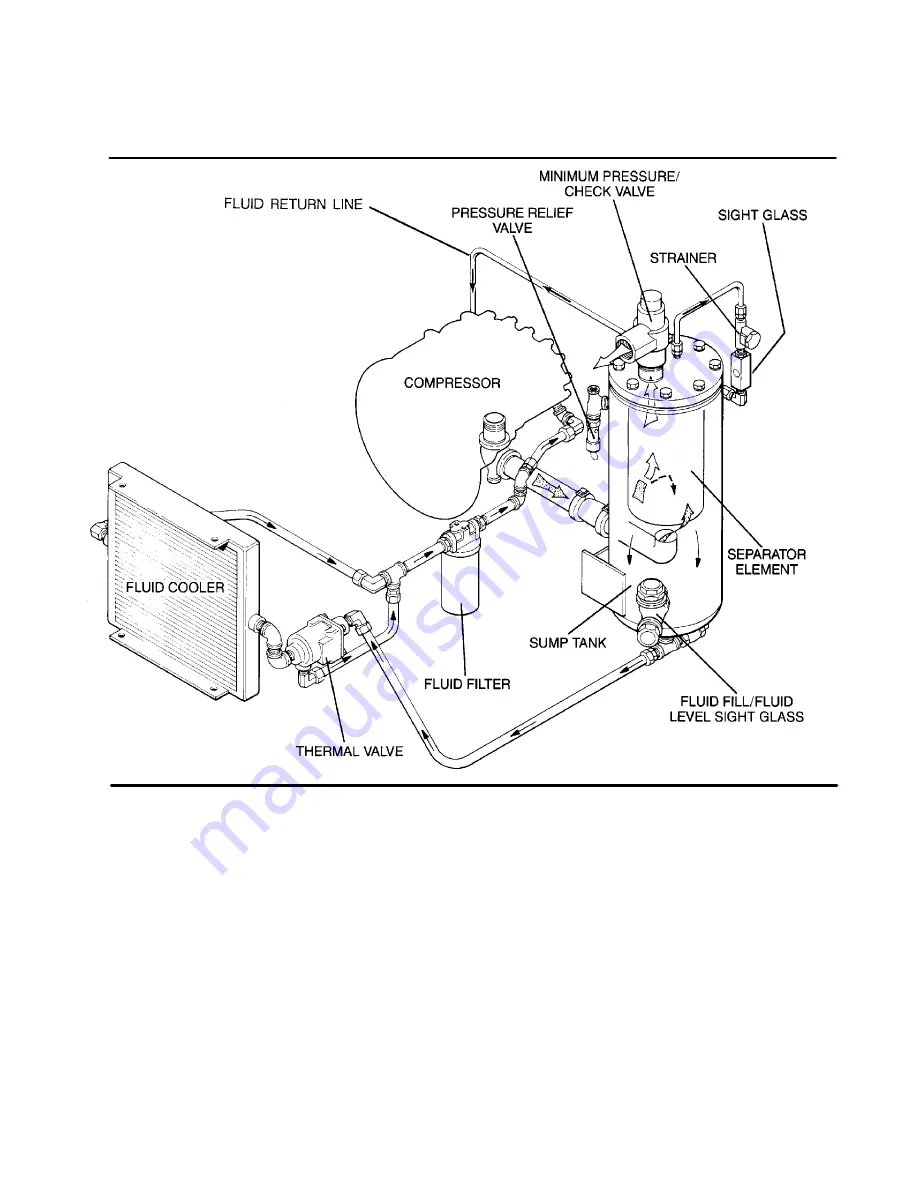

Figure 2---4 Compressor Discharge/Cooling and Lubrication System (Air---Cooled)

Sullair recommends that a 24KT sample be taken

at the first filter change and sent to the factory for

analysis. This is a free service. The sample kit with

instruction and self addressed container is sup-

plied with your compressor. The user will receive an

analysis report with recommendations.

For the water---cooled models, a shell and tube

heat exchanger and water---flow regulating valve

are substituted for the radiator---type cooler and

cooler bypass valve listed above.

The pressure in the receiver/sump causes fluid flow

by forcing the fluid from the high pressure area of

the sump to an area of lower pressure in the com-

pressor unit.

On air---cooled models, the fluid flows from the bot-

tom of the receiver/sump to the thermal valve. The

thermal valve has a nominal temperature of 170

_

F

(77

_

C). At low temperatures, the fluid passes

through the thermal valve, the filter and directly to

the compressor unit.

As the discharge temperature rises above 170

_

F

(77

_

C), due to the heat of compression, the ther-

mal valve begins to close and a portion of the fluid

then flows through the cooler; from the cooler to the

filter, and on to the compressor unit.

On water---cooled models, a water---flow regulating

valve will regulate the amount of cooling necessary

to maintain the proper operating temperature.

When the fluid leaves the sump it is directed to the

cooler. Depending on the temperature of the fluid,

the water---flow regulating valve allows the proper

Summary of Contents for 10B 25HP

Page 2: ...NOTE For Additional Information on 24KT Units See Inside Back Cover...

Page 4: ...NOTES...

Page 22: ...16 NOTES...

Page 24: ...Section 4 INSTALLATION 18 Figure 4 1 Piping and Instruments...

Page 26: ...20 NOTES...

Page 42: ...36 NOTES...

Page 44: ...NOTES...

Page 45: ......