Section 6

MAINTENANCE

25

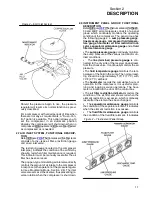

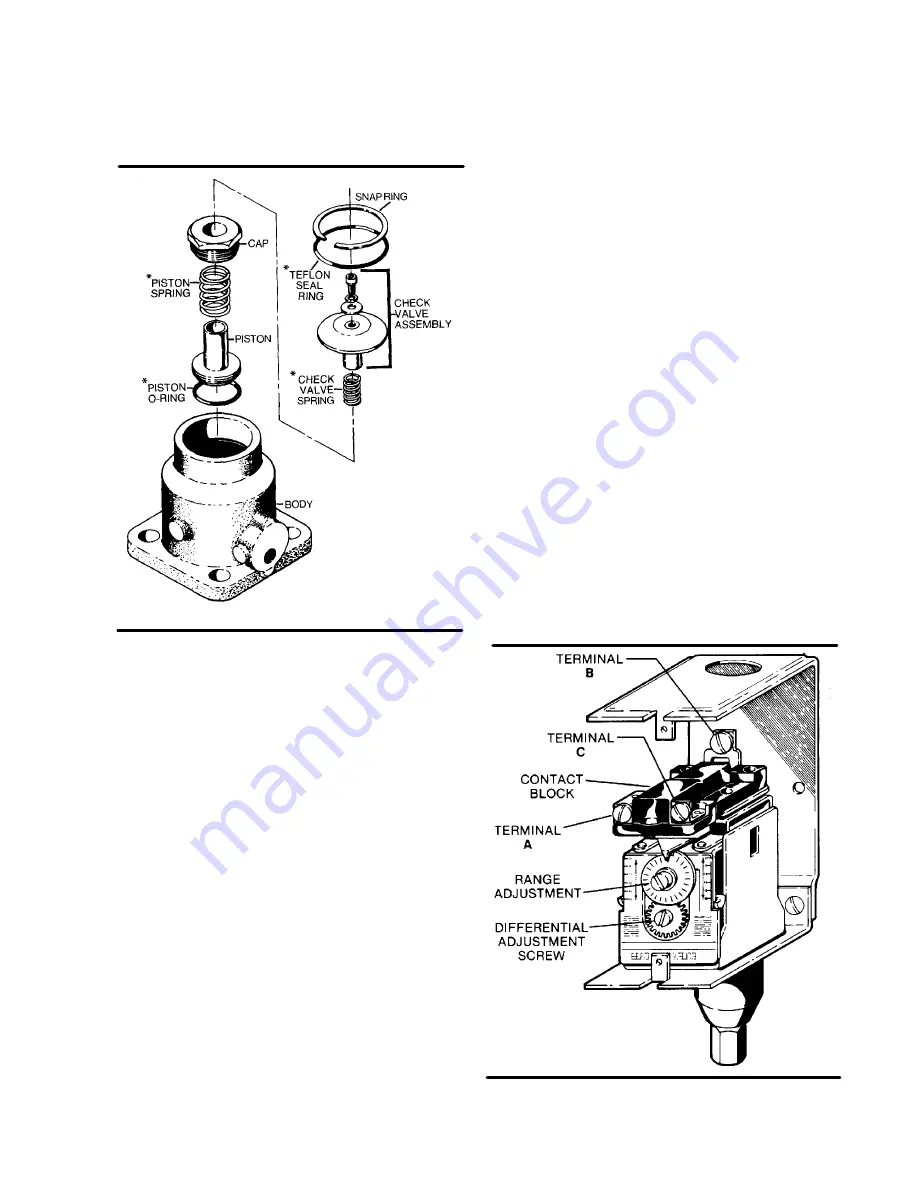

Figure 6---4 Inlet Valve (250025---654)

* Repair Kit P/N 250019---451

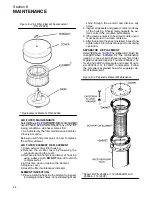

1. Relieve all pressure from the sump tank and all

compressor lines.

2. Disconnect all piping connected to the sump

cover to allow removal (return lines, service

lines, etc.).

3. Loosen and remove the hex head capscrews

from the cover plate.

4. Lift the cover plate from the sump.

5. Remove the separator element.

6. Scrape the old gasket material from the cover

and flange on the sump. Be careful not to let the

scraps fall in the sump.

7. Install the new gaskets; one on the sump tank

the other on top of the element.

8. Reinsert the separator element into the sump

taking care not to dent it against the tank open-

ing.

9. Clean the cover plate, washers and capscrews.

Torque to 55 ft.---lbs. (75 Nm).

10. Reconnect all piping making sure return line

tube extends

!

@

4

” (6mm)above the bottom of the

separator element. This will assure proper fluid

return flow to the compressor.

11. Clean the return line strainer before restarting

the compressor.

INLET VALVE MAINTENANCE

. The inlet va lve (P/ N

250025---654) maintenance may require the re-

placement of the piston spring, piston o---ring, seal

ring, and check valve spring. Use repair kit number

250019---451 and follow the procedure below for

proper installation.

1. Remove all piping connected to inlet valve as-

sembly.

2. Remove the four (4) capscrews and lock-

washers that attach the valve body to the com-

pressor unit and remove from compressor.

3. Remove snap ring and Teflon o---ring inside

valve body.

4. Lift and remove check valve assembly and

spring from valve body.

5. Remove piston cap, piston spring, and piston.

6. Clean valve body as needed, making sure all air

passages are clear and old seal ring is removed

from the inlet body flange.

7. The next step is to reassemble the inlet valve us-

ing the new parts supplied in the repair kit.

8. Install o---ring on piston, lightly oil piston, and in-

stall in valve body.

9. Install new piston spring and replace piston cap.

10. Place new check valve spring into piston and in-

stall check valve assembly

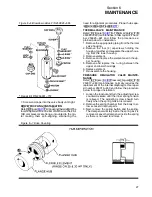

CONTROL SYSTEM ADJUSTMENT

. Prior t o a dj usting the Control

System, it is necessary to determine t he desired

operating pressure range and also the maximum

pressure at which your compressor is to operate.

The pressure must not exceed the maximum oper-

Figure 6---5 Pressure Switch (P/N 040694)

Summary of Contents for 10B 25HP

Page 2: ...NOTE For Additional Information on 24KT Units See Inside Back Cover...

Page 4: ...NOTES...

Page 22: ...16 NOTES...

Page 24: ...Section 4 INSTALLATION 18 Figure 4 1 Piping and Instruments...

Page 26: ...20 NOTES...

Page 42: ...36 NOTES...

Page 44: ...NOTES...

Page 45: ......