Section 2

DESCRIPTION

10

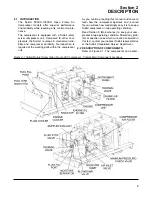

blies of the Sullair 900XH-1350XH Open Frame Air

Compressors models are clearly shown. The pack-

age includes a

compressor unit

,

diesel engine

,

compressor inlet system

,

compressor cooling

and lubrication system

,

compressor discharge

system

,

capacity control system

,

instrument

panel

and

electrical system

. The Sullair com-

pressor unit is driven by an industrial engine

designed to provide enough horsepower for more

than adequate reserve at rated conditions. Refer to

Engine Operator's Manual for a more detailed

description of the engine.

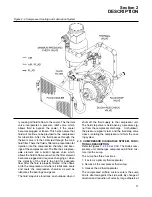

The

engine cooling system

is comprised of a

radiator

,

high capacity fan

and

thermostats

. The

high capacity fan draws air through the radiator,

keeping the engine at the proper operating temper-

ature.

The same fan also cools the fluid in the compressor

cooling and lubrication system. Prior to passing

through the radiator, the fan air also passes through

the compressor fluid cooler (which is mounted adja-

cent to the radiator). As air passes through the

cooler, the heat of compression is removed from the

fluid.

The same fan also cools the engines intake air sup-

ply. Prior to passing through the radiator and oil

cooler, the fan air passes through an air to air after-

cooler. As air passes through the air to air after-

cooler heat is removed which was introduced by the

engine's turbo charger. The engine is coupled to

the compressor unit with a non-lubricated vulcan-

ized rubber disc and drive flange-type coupling.

On open frame compressors supplied without fuel

tanks, the customer is responsible for providing

fuel supply.

2.3 SULLAIR COMPRESSOR UNIT, FUNCTIONAL

DESCRIPTION

Sullair compressors feature the Sullair compressor

unit, a two-stage, positive displacement, flood lubri-

cated-type compressor. This unit provides continu-

ous compression to meet your needs. With a Sullair

compressor, no maintenance or inspection of the

internal parts of the compressor unit is required with

the warranty.

Fluid is injected into the compressor unit and mixes

directly with the air as the rotors turn, compressing

the air. The fluid flow has three basic functions:

1. As coolant, it controls the rise of air temperature

normally associated with the heat of compres-

sion.

2. Seals the leakage paths between the rotors and

the stator and also between the rotors them-

selves.

3. Acts as a lubricating film between the rotors

allowing one rotor to directly drive the other,

which is an idler.

After the air/fluid mixture is discharged from the

compressor unit, the fluid is separated from the air.

At this time, the air flows to your service line and the

fluid is cooled in preparation for re-injection.

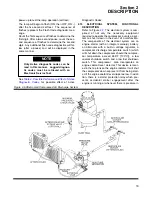

2.4 COMPRESSOR COOLING AND LUBRICATION

SYSTEM, FUNCTIONAL DESCRIPTION

(Standard) or

(Aftercooled). The

compressor cooling and lubri-

cation system

is designed to provide adequate

lubrication as well as maintain the proper operating

temperature of the compressor. In addition to the

cooler

and

fan

, the system consists of a

main fil-

ter

,

fluid stop valve

and

thermal valve

.

Fluid is used in the system as a coolant and a lubri-

cant. The fluid is housed in the receiver/sump which

from this time on will be referred to as the sump.

Upon start-up, the temperature of the fluid is cool

and routing to the fluid cooler is not necessary. The

fluid, taking the path of least resistance, flows to the

thermal valve.

The thermal valve has two entrance ports and two

exit ports. The entrance ports will be referred to as

Port A and Port B. Port A accepts fluid from the

sump and Port B accepts fluid from the cooler. The

exit ports will be referred to as Port C and Port D.

Port C routes fluid to the cooler and Port D routes

fluid to the compressor.

As previously stated, upon start-up, the fluid tem-

perature is cool, and routing to the cooler is not

required. The fluid first enters the thermal valve

through Port A and then flows on to the compressor

unit through Port D, bypassing the cooler. As the

compressor continues to operate, the temperature

of the fluid rises and the thermal valve element

begins to shift. This forces a portion of the fluid to

the fluid cooler through Port C. The cooler is a radi-

ator-type that works in conjunction with the engine

fan. The fan draws air through the cooler removing

the heat of compression from the fluid. From the

cooler, the fluid is routed back to the thermal valve,

entering at Port B. Before the temperature of the

fluid becomes high enough that Port A is complete-

ly shifted, cooled fluid entering at Port B is mixed

with warmer fluid entering at Port A. When the tem-

perature of the fluid entering at Port A reaches

210°F (99°C), the thermal element shifts complete-

Summary of Contents for 1350XH

Page 6: ......

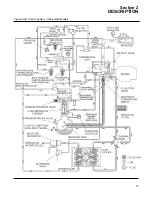

Page 18: ...Section 2 DESCRIPTION 12 Figure 2 3A Control System 900XH 1150XH and 1350XH Models...

Page 19: ...Section 2 DESCRIPTION 13 Figure 2 3B Control System Aftercooled Models...

Page 29: ...Section 2 DESCRIPTION 23 Figure 2 7 Wiring Diagram 02250145 161R01...

Page 30: ...NOTES 24...

Page 33: ...Section 3 SPECIFICATIONS 27 02250135 977R03 Figure 3 2 Identification Compressor Assembly...

Page 34: ...NOTES 28...

Page 38: ...NOTES 32...

Page 54: ...Section 7 ILLUSTRATIONS AND PARTS 48 02250127 622R08 7 3 ENGINE AND COMPRESSOR MOUNTING...

Page 56: ...Section 7 ILLUSTRATIONS AND PARTS 50 02250127 622R08 7 3 ENGINE AND COMPRESSOR MOUNTING...

Page 58: ...Section 7 ILLUSTRATIONS AND PARTS 52 02250136 060R02 7 4 AIR INLET SYSTEM ALL MODELS...

Page 60: ...Section 7 ILLUSTRATIONS AND PARTS 54 02250136 060R02 7 4 AIR INLET SYSTEM ALL MODELS...

Page 62: ...Section 7 ILLUSTRATIONS AND PARTS 56 02250136 062R02 7 5 EXHAUST SYSTEM ALL MODELS...

Page 72: ...Section 7 ILLUSTRATIONS AND PARTS 66 02250127 633R02 7 7 ENGINE RADIATOR ASSEMBLY ALL MODELS...

Page 74: ...Section 7 ILLUSTRATIONS AND PARTS 68 7 8 AFTERCOOLER MOUNTING ALL MODELS 02250150 135R03...

Page 82: ...Section 7 ILLUSTRATIONS AND PARTS 76 02250140 983R01 7 12A INLET VALVE AND PARTS 6 5 900XH...

Page 86: ...Section 7 ILLUSTRATIONS AND PARTS 80 02250054 762R06 7 13A INLET VALVE PARTS 6 5 900XH...

Page 90: ...Section 7 ILLUSTRATIONS AND PARTS 84 02250127 667R10 7 14A DISCHARGE SYSTEM 900XH AND 1150XH...

Page 96: ...Section 7 ILLUSTRATIONS AND PARTS 90 02250148 288R01 7 14C DISCHARGE SYSTEM 1350XH AFTERCOOLED...

Page 98: ...Section 7 ILLUSTRATIONS AND PARTS 92 02250148 288R01 7 14C DISCHARGE SYSTEM 1350XH AFTERCOOLED...

Page 116: ...Section 7 ILLUSTRATIONS AND PARTS 110 02250164 870R01 7 19 MINIMUM PRESSURE CHECK VALVE...

Page 118: ...Section 7 ILLUSTRATIONS AND PARTS 112 02250136 066R00 7 20 FUEL SYSTEM AND PARTS ALL MODELS...

Page 120: ...Section 7 ILLUSTRATIONS AND PARTS 114 02250127 727R01 7 21 ELECTRICAL PARTS ALL MODELS...

Page 126: ...Section 7 ILLUSTRATIONS AND PARTS 120 02250136 503R02 7 23 FRAME AND PARTS...

Page 128: ...Section 7 ILLUSTRATIONS AND PARTS 122 7 24 DECAL GROUP...

Page 130: ...Section 7 ILLUSTRATIONS AND PARTS 124 7 24 DECAL GROUP...

Page 132: ...Section 7 ILLUSTRATIONS AND PARTS 126 7 24 DECAL GROUP...

Page 134: ...Section 7 ILLUSTRATIONS AND PARTS 128 7 24 DECAL GROUP...

Page 136: ...Section 7 ILLUSTRATIONS AND PARTS 130 7 25 DECAL LOCATIONS 02250136 067R03...

Page 138: ...Section 7 ILLUSTRATIONS AND PARTS 132 7 25 DECAL LOCATIONS 02250136 067R03...

Page 140: ...NOTES 134...

Page 141: ......