Section 4

OPERATION

29

4.1 GENERAL

While Sullair has built into this compressor a com-

prehensive array of controls and indicators to

assure you that it is operating properly, you will

want to recognize and interpret the reading which

will call for service or indicate the beginning of a

malfunction. Before starting your Sullair compres-

sor, read this section thoroughly and familiarize

yourself with the controls and indicators - their pur-

pose, location and use.

Continued on page 30

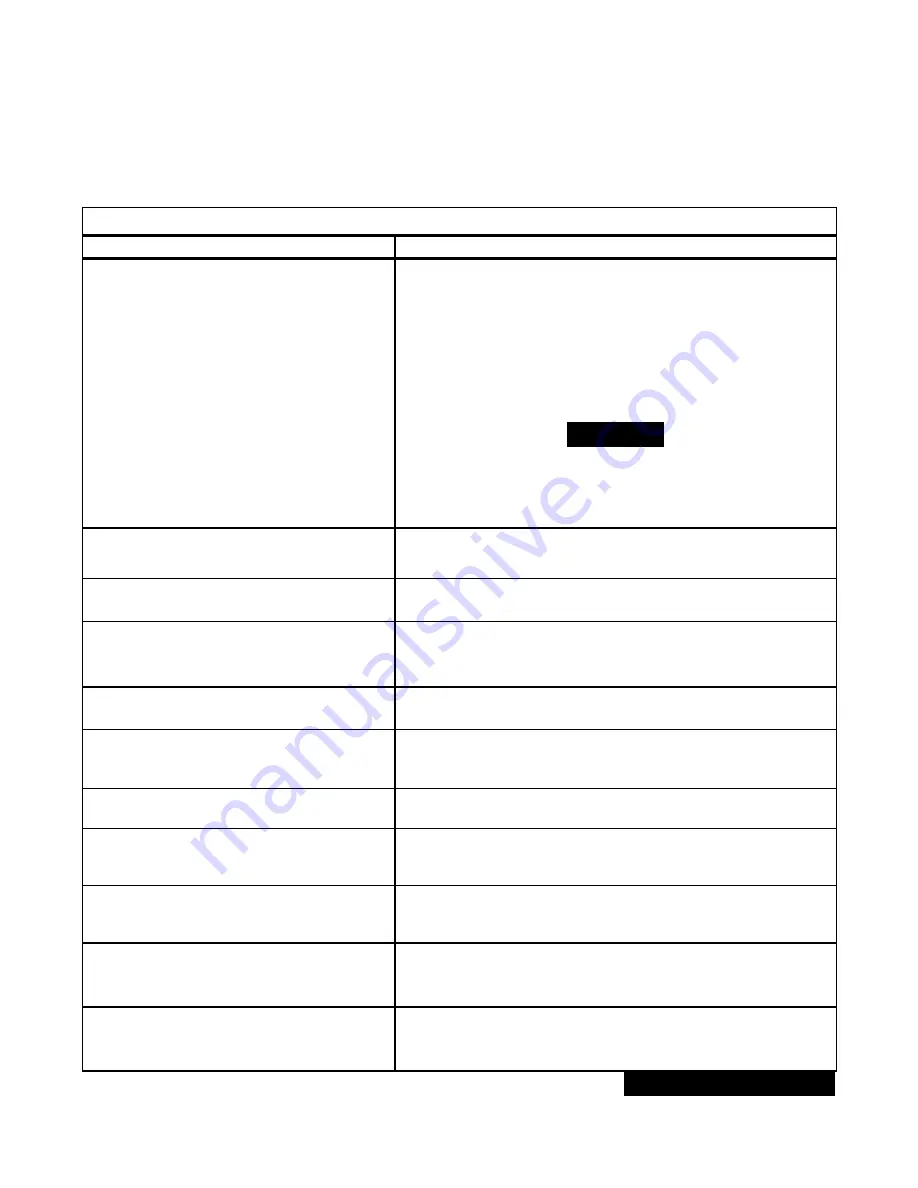

4.2 PURPOSE OF CONTROLS

CONTROL OR INDICATOR

PURPOSE

ENGINE SWITCH

The engine switch is used to both energize the compressor’s

electrical system and engage the engine/starter. The rotary

type switch works similar to an automotive key switch; it turns

in a clockwise direction with “off” being the first position, “igni-

tion” the second and “start” being the third position. It also has

a built-in anti-restart device that protects the starter fromen-

gaging while the engine is running. The switch must be turned

back to the “off” position before the engine can be re-started.

When re-starting the compressor,make sure receiver

tank pressure has blown down to (10 psig 0.7 bar) or

less. More than 0.7 bar (10 psig ) can put extra load on

the starter.

NOTE

VOLTMETER

Monitors the condition of the batteries and the charging

circuit. The normal reading is 24 to 28 volts.

AIR PRESSURE GAUGE

Continually monitors the pressure inside the receiver tank at

various load and unload conditions.

ENGINE WATER TEMPERATURE GAUGE

Monitors the temperature of the engine water. The normal

operating temperature should read approximately 160°F to

210°F (71°C to 99°C ).

EMS (ENGINE MONITORING SYSTEM)

Depicts system-related diagnostics. Can be used for system

performance monitoring.

COMPRESSOR DISCHARGE TEMPERATURE

GAUGE

Monitors the temperature of the air/fluid mixture leaving the

compressor unit. The normal reading should be approximately

200°F to 230°F (93°C to 110°C).

SYSTEM PRESSURE SWITCH

Prevents starter engagement when the air system is pressur-

ized.

FLUID LEVEL SIGHT GLASS

Monitors the fluid level in the sump. Proper level is always

visible in the sight glass. Check the level when the compres-

sor is shut down.

COMPRESSOR DISCHARGE TEMPERATURE

Opens the electrical circuit to shut down the compressor

when the discharge temperature reaches 265°F (124°C) or

250°F (121°C) for interstage.

REDUCING REGULATOR VALVE

Provides regulated air pressure to the inlet valve and engine

speed control to open the inlet valve and move engine gover-

nor to full speed with warm-up valve in the“run” position.

BACK PRESSURE REGULATING VALVE

Provides an air signal to the inlet valve and engine speed

cylinder to close the inlet valve and reduce engine speed to

control air delivery according to demand.

Summary of Contents for 1350XH

Page 6: ......

Page 18: ...Section 2 DESCRIPTION 12 Figure 2 3A Control System 900XH 1150XH and 1350XH Models...

Page 19: ...Section 2 DESCRIPTION 13 Figure 2 3B Control System Aftercooled Models...

Page 29: ...Section 2 DESCRIPTION 23 Figure 2 7 Wiring Diagram 02250145 161R01...

Page 30: ...NOTES 24...

Page 33: ...Section 3 SPECIFICATIONS 27 02250135 977R03 Figure 3 2 Identification Compressor Assembly...

Page 34: ...NOTES 28...

Page 38: ...NOTES 32...

Page 54: ...Section 7 ILLUSTRATIONS AND PARTS 48 02250127 622R08 7 3 ENGINE AND COMPRESSOR MOUNTING...

Page 56: ...Section 7 ILLUSTRATIONS AND PARTS 50 02250127 622R08 7 3 ENGINE AND COMPRESSOR MOUNTING...

Page 58: ...Section 7 ILLUSTRATIONS AND PARTS 52 02250136 060R02 7 4 AIR INLET SYSTEM ALL MODELS...

Page 60: ...Section 7 ILLUSTRATIONS AND PARTS 54 02250136 060R02 7 4 AIR INLET SYSTEM ALL MODELS...

Page 62: ...Section 7 ILLUSTRATIONS AND PARTS 56 02250136 062R02 7 5 EXHAUST SYSTEM ALL MODELS...

Page 72: ...Section 7 ILLUSTRATIONS AND PARTS 66 02250127 633R02 7 7 ENGINE RADIATOR ASSEMBLY ALL MODELS...

Page 74: ...Section 7 ILLUSTRATIONS AND PARTS 68 7 8 AFTERCOOLER MOUNTING ALL MODELS 02250150 135R03...

Page 82: ...Section 7 ILLUSTRATIONS AND PARTS 76 02250140 983R01 7 12A INLET VALVE AND PARTS 6 5 900XH...

Page 86: ...Section 7 ILLUSTRATIONS AND PARTS 80 02250054 762R06 7 13A INLET VALVE PARTS 6 5 900XH...

Page 90: ...Section 7 ILLUSTRATIONS AND PARTS 84 02250127 667R10 7 14A DISCHARGE SYSTEM 900XH AND 1150XH...

Page 96: ...Section 7 ILLUSTRATIONS AND PARTS 90 02250148 288R01 7 14C DISCHARGE SYSTEM 1350XH AFTERCOOLED...

Page 98: ...Section 7 ILLUSTRATIONS AND PARTS 92 02250148 288R01 7 14C DISCHARGE SYSTEM 1350XH AFTERCOOLED...

Page 116: ...Section 7 ILLUSTRATIONS AND PARTS 110 02250164 870R01 7 19 MINIMUM PRESSURE CHECK VALVE...

Page 118: ...Section 7 ILLUSTRATIONS AND PARTS 112 02250136 066R00 7 20 FUEL SYSTEM AND PARTS ALL MODELS...

Page 120: ...Section 7 ILLUSTRATIONS AND PARTS 114 02250127 727R01 7 21 ELECTRICAL PARTS ALL MODELS...

Page 126: ...Section 7 ILLUSTRATIONS AND PARTS 120 02250136 503R02 7 23 FRAME AND PARTS...

Page 128: ...Section 7 ILLUSTRATIONS AND PARTS 122 7 24 DECAL GROUP...

Page 130: ...Section 7 ILLUSTRATIONS AND PARTS 124 7 24 DECAL GROUP...

Page 132: ...Section 7 ILLUSTRATIONS AND PARTS 126 7 24 DECAL GROUP...

Page 134: ...Section 7 ILLUSTRATIONS AND PARTS 128 7 24 DECAL GROUP...

Page 136: ...Section 7 ILLUSTRATIONS AND PARTS 130 7 25 DECAL LOCATIONS 02250136 067R03...

Page 138: ...Section 7 ILLUSTRATIONS AND PARTS 132 7 25 DECAL LOCATIONS 02250136 067R03...

Page 140: ...NOTES 134...

Page 141: ......