Section 5

MAINTENANCE

33

5.1 GENERAL

A good maintenance program is the key to long

compressor life. Below is a program that when

adhered to, should keep the compressor in top

operating condition. For engine maintenance

requirements, refer to the Engine Operator's

Manual for a detailed description of service instruc-

tions. See Parts Replacement and Adjustment

Procedures for a detailed description of specific

compressor system components. Prior to perform-

ing maintenance, read the CIMA Safety Manual, if

applicable.

Stop compressor and relieve all internal pressure

before doing so.

5.2 DAILY OPERATION

Prior to starting the compressor, it is necessary to

check the fluid level in the sump. Should the level

be low, simply add the necessary amount. If the

addition of fluid becomes too frequent, a simple

problem has developed which is causing this

excessive loss. See the Troubleshooting Section

(5.11) under Excessive Fluid Consumption for a

probable cause and remedy. Also check the engine

oil level and the radiator coolant level prior to start-

ing.

After a routine start has been made, observe the

instrument panel gauges and be sure they monitor

the correct readings for their particular phase of

operation. After the compressor has warmed up, it

is recommended that a general check on the over-

all compressor and instrument panel be made to

assure that the compressor is running properly.

Also check the air filter restriction gauges. Should

they indicate restriction, replace the elements

immediately (see Air Filter Maintenance in Section

5.10).

5.3 MAINTENANCE AFTER INITIAL 50 HOURS OF

OPERATION

After the initial 50 hours of operation, a few simple

maintenance routines can rid the system of any

possible foreign materials, if any. Perform the fol-

lowing maintenance operations to prevent unnec-

essary problems.

1. Clean the return line orifice and strainer.

2. Change compressor fluid filter.

3. Check Engine Operator's Manual for required

service.

5.4 MAINTENANCE EVERY 100 HOURS

After 100 hours of operation, it will be necessary to

perform the following:

1. Check the battery level and fill with water if nec-

essary.

5.5 MAINTENANCE EVERY 250 HOURS

Perform the following after every 250 hours of oper-

ation:

1. Check fan belt tension.

2. Clean the radiator and cooler exterior. Depending

on how contaminated the atmosphere may be,

more frequent cooler and radiator cleaning may

be necessary. To clean between fluid cooler and

radiator, the three (3) bolts securing the top of

the fluid cooler to the top mounting bracket

should be removed, allowing the fluid cooler to

swing down on its lower hinge. This will allow

easier access to clean between the fluid cooler

and radiator cores.

3. Check Engine Operator's Manual for required

service.

4. Change the engine oil and oil filter. This is best

done when the engine is hot.

5.6 MAINTENANCE EVERY 300 HOURS

When using fluids other than Sullair AWF, change

the compressor fluid and replace the fluid filter ele-

ment (See maintenance procedure in Section 5.10).

5.7 MAINTENANCE EVERY 500 HOURS

When using Sullair AWF, replace the fluid filter ele-

ment and change compressor fluid. (See mainte-

nance procedures in Section 5.10).

5.8 MAINTENANCE EVERY 1000 HOURS

Perform the following after every 1000 hours of

operation:

DO NOT

remove caps, plugs and/or

other components when compressor is

running or pressurized.

Stop compressor and relieve all inter-

nal pressure before doing so.

WARNING

The radiator and engine cooling sys-

tem must be drained and flushed every

two (2) years. Replace the coolant with

a solution of 50% ethylene glycol and

50% water or as required for your geo-

graphic location.

DO NOT

use a leak

sealing type of anti-freeze. Should a

100% water solution be used, a non-

chromate rust inhibitor must be added.

NOTE

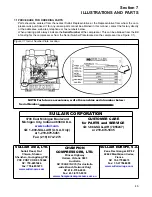

Summary of Contents for 1350XH

Page 6: ......

Page 18: ...Section 2 DESCRIPTION 12 Figure 2 3A Control System 900XH 1150XH and 1350XH Models...

Page 19: ...Section 2 DESCRIPTION 13 Figure 2 3B Control System Aftercooled Models...

Page 29: ...Section 2 DESCRIPTION 23 Figure 2 7 Wiring Diagram 02250145 161R01...

Page 30: ...NOTES 24...

Page 33: ...Section 3 SPECIFICATIONS 27 02250135 977R03 Figure 3 2 Identification Compressor Assembly...

Page 34: ...NOTES 28...

Page 38: ...NOTES 32...

Page 54: ...Section 7 ILLUSTRATIONS AND PARTS 48 02250127 622R08 7 3 ENGINE AND COMPRESSOR MOUNTING...

Page 56: ...Section 7 ILLUSTRATIONS AND PARTS 50 02250127 622R08 7 3 ENGINE AND COMPRESSOR MOUNTING...

Page 58: ...Section 7 ILLUSTRATIONS AND PARTS 52 02250136 060R02 7 4 AIR INLET SYSTEM ALL MODELS...

Page 60: ...Section 7 ILLUSTRATIONS AND PARTS 54 02250136 060R02 7 4 AIR INLET SYSTEM ALL MODELS...

Page 62: ...Section 7 ILLUSTRATIONS AND PARTS 56 02250136 062R02 7 5 EXHAUST SYSTEM ALL MODELS...

Page 72: ...Section 7 ILLUSTRATIONS AND PARTS 66 02250127 633R02 7 7 ENGINE RADIATOR ASSEMBLY ALL MODELS...

Page 74: ...Section 7 ILLUSTRATIONS AND PARTS 68 7 8 AFTERCOOLER MOUNTING ALL MODELS 02250150 135R03...

Page 82: ...Section 7 ILLUSTRATIONS AND PARTS 76 02250140 983R01 7 12A INLET VALVE AND PARTS 6 5 900XH...

Page 86: ...Section 7 ILLUSTRATIONS AND PARTS 80 02250054 762R06 7 13A INLET VALVE PARTS 6 5 900XH...

Page 90: ...Section 7 ILLUSTRATIONS AND PARTS 84 02250127 667R10 7 14A DISCHARGE SYSTEM 900XH AND 1150XH...

Page 96: ...Section 7 ILLUSTRATIONS AND PARTS 90 02250148 288R01 7 14C DISCHARGE SYSTEM 1350XH AFTERCOOLED...

Page 98: ...Section 7 ILLUSTRATIONS AND PARTS 92 02250148 288R01 7 14C DISCHARGE SYSTEM 1350XH AFTERCOOLED...

Page 116: ...Section 7 ILLUSTRATIONS AND PARTS 110 02250164 870R01 7 19 MINIMUM PRESSURE CHECK VALVE...

Page 118: ...Section 7 ILLUSTRATIONS AND PARTS 112 02250136 066R00 7 20 FUEL SYSTEM AND PARTS ALL MODELS...

Page 120: ...Section 7 ILLUSTRATIONS AND PARTS 114 02250127 727R01 7 21 ELECTRICAL PARTS ALL MODELS...

Page 126: ...Section 7 ILLUSTRATIONS AND PARTS 120 02250136 503R02 7 23 FRAME AND PARTS...

Page 128: ...Section 7 ILLUSTRATIONS AND PARTS 122 7 24 DECAL GROUP...

Page 130: ...Section 7 ILLUSTRATIONS AND PARTS 124 7 24 DECAL GROUP...

Page 132: ...Section 7 ILLUSTRATIONS AND PARTS 126 7 24 DECAL GROUP...

Page 134: ...Section 7 ILLUSTRATIONS AND PARTS 128 7 24 DECAL GROUP...

Page 136: ...Section 7 ILLUSTRATIONS AND PARTS 130 7 25 DECAL LOCATIONS 02250136 067R03...

Page 138: ...Section 7 ILLUSTRATIONS AND PARTS 132 7 25 DECAL LOCATIONS 02250136 067R03...

Page 140: ...NOTES 134...

Page 141: ......