Section 1

SAFETY

5

to refueling.

B.

Clean up spills of fuel, fluid, battery electrolyte or

coolant immediately if such spills occur.

C.

Shut off air compressor and allow it to cool.

Then keep sparks, flames and other sources of igni-

tion away and

DO NOT

permit smoking in the vicin-

ity when adding fuel, or when checking or adding

electrolyte to batteries, or when checking or adding

fluid, or when checking diesel engine ether starting

aid systems or replacing cylinders, or when refilling

air line anti-icer systems antifreeze compound.

D. DO NOT

permit liquids, including air line anti-icer

system antifreeze compound or fluid film to accu-

mulate on bottom covers or on, under or around

acoustical material, or on any external or internal

surfaces of the air compressor. Wipe down using an

aqueous industrial cleaner or steam clean as

required. If necessary remove acoustical material,

clean all surfaces and then replace acoustical

material. Any acoustical material with a protective

covering that has been torn or punctured should be

replaced immediately to prevent accumulation of

liquids or fluid film within the material.

DO NOT

use

flammable solvents for cleaning purposes.

E.

Disconnect the grounded (negative) battery con-

nection prior to attempting any repairs or cleaning

inside the enclosure. Tag the battery connections

so others will not unexpectedly reconnect it.

F.

Keep electrical wiring, including the battery ter-

minals and other terminals, in good condition.

Replace any wiring that has cracked, cut abraded

or otherwise degraded insulation or terminals that

are worn, discolored or corroded. Keep all termi-

nals clean and tight.

G.

Turn off battery charger before making or break-

ing connections to the battery.

H.

Keep grounded conductive objects such as tools

away from exposed live electrical parts such as ter-

minals to avoid arcing which might serve as a

source of ignition.

I.

Replace damaged fuel tanks or lines immediately

rather than attempt to weld or otherwise repair

them.

DO NOT

store or attempt to operate the

compressor with any known leaks in the fuel sys-

tem. Tag the compressor and render it inoperative

until repair can be made.

J.

Remove any acoustical material or other materi-

al that may be damaged by heat or that may sup-

port combustion prior to attempting weld repairs.

Remove diesel engine ether starting aid cylinders

and air line anti-icer system components containing

antifreeze compound, prior to attempting weld

repairs in any place other than the fuel system.

DO

NOT

weld on or near the fuel system.

K.

Keep a suitable fully charged class BC or ABC

fire extinguisher or extinguishers nearby when serv-

icing and operating the compressor.

L.

Keep oily rags, trash, leaves, litter or other com-

bustibles out of and away from the compressor.

M.

Open all access doors and allow the enclosure

to ventilate thoroughly prior to attempting to start

the engine.

N. DO NOT

operate compressor under low over-

hanging leaves or permit such leaves to contact hot

exhaust system surfaces when operating the com-

pressor in forested areas.

O.

Ethyl ether used in diesel engine ether starting

aid systems is extremely flammable. Change cylin-

ders, or maintain or troubleshoot these systems

only in well-ventilated areas away from heat, open

flame or sparks.

DO NOT

install, store or otherwise

expose ether cylinders to temperatures above

160°F (71°C). Remove ether cylinder from the com-

pressor when operating in ambient temperatures

above 60°F (16°C).

P. DO NOT

attempt to use ether as a starting aid in

gasoline engines or diesel engines with glow plugs

as serious personnel injury or property damage

may result.

Q. DO NOT

spray ether into compressor air filter or

into an air filter that serves both the engine and the

compressor as serious damage to the compressor

or personal injury may result.

R.

Antifreeze compound used in air line anti-icer

systems contains methanol which is flammable.

Use systems and refill with compound only in well-

ventilated areas away from heat, open flames or

sparks.

DO NOT

expose any part of these systems

or the antifreeze compound to temperatures above

150°F (66°C). Vapors from the antifreeze com-

pound are heavier than air.

DO NOT

store com-

pound or discharge treated air in confined or unven-

tilated areas.

DO NOT

store containers or

antifreeze compound in direct sunlight.

S.

Store flammable fluids and materials away from

your work area. Know where fire extinguishers are

and how to use them, and for what type of fire they

are intended. Check readiness of fire suppression

systems and detectors if so equipped.

1.5 MOVING PARTS

A.

Keep hands, arms and other parts of the body

and also clothing away from belts, pulleys and other

Summary of Contents for 1350XH

Page 6: ......

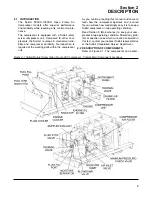

Page 18: ...Section 2 DESCRIPTION 12 Figure 2 3A Control System 900XH 1150XH and 1350XH Models...

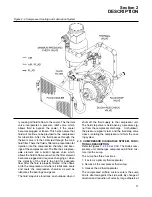

Page 19: ...Section 2 DESCRIPTION 13 Figure 2 3B Control System Aftercooled Models...

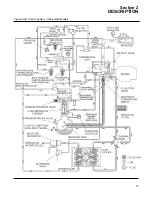

Page 29: ...Section 2 DESCRIPTION 23 Figure 2 7 Wiring Diagram 02250145 161R01...

Page 30: ...NOTES 24...

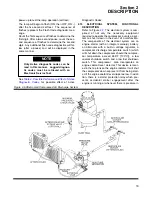

Page 33: ...Section 3 SPECIFICATIONS 27 02250135 977R03 Figure 3 2 Identification Compressor Assembly...

Page 34: ...NOTES 28...

Page 38: ...NOTES 32...

Page 54: ...Section 7 ILLUSTRATIONS AND PARTS 48 02250127 622R08 7 3 ENGINE AND COMPRESSOR MOUNTING...

Page 56: ...Section 7 ILLUSTRATIONS AND PARTS 50 02250127 622R08 7 3 ENGINE AND COMPRESSOR MOUNTING...

Page 58: ...Section 7 ILLUSTRATIONS AND PARTS 52 02250136 060R02 7 4 AIR INLET SYSTEM ALL MODELS...

Page 60: ...Section 7 ILLUSTRATIONS AND PARTS 54 02250136 060R02 7 4 AIR INLET SYSTEM ALL MODELS...

Page 62: ...Section 7 ILLUSTRATIONS AND PARTS 56 02250136 062R02 7 5 EXHAUST SYSTEM ALL MODELS...

Page 72: ...Section 7 ILLUSTRATIONS AND PARTS 66 02250127 633R02 7 7 ENGINE RADIATOR ASSEMBLY ALL MODELS...

Page 74: ...Section 7 ILLUSTRATIONS AND PARTS 68 7 8 AFTERCOOLER MOUNTING ALL MODELS 02250150 135R03...

Page 82: ...Section 7 ILLUSTRATIONS AND PARTS 76 02250140 983R01 7 12A INLET VALVE AND PARTS 6 5 900XH...

Page 86: ...Section 7 ILLUSTRATIONS AND PARTS 80 02250054 762R06 7 13A INLET VALVE PARTS 6 5 900XH...

Page 90: ...Section 7 ILLUSTRATIONS AND PARTS 84 02250127 667R10 7 14A DISCHARGE SYSTEM 900XH AND 1150XH...

Page 96: ...Section 7 ILLUSTRATIONS AND PARTS 90 02250148 288R01 7 14C DISCHARGE SYSTEM 1350XH AFTERCOOLED...

Page 98: ...Section 7 ILLUSTRATIONS AND PARTS 92 02250148 288R01 7 14C DISCHARGE SYSTEM 1350XH AFTERCOOLED...

Page 116: ...Section 7 ILLUSTRATIONS AND PARTS 110 02250164 870R01 7 19 MINIMUM PRESSURE CHECK VALVE...

Page 118: ...Section 7 ILLUSTRATIONS AND PARTS 112 02250136 066R00 7 20 FUEL SYSTEM AND PARTS ALL MODELS...

Page 120: ...Section 7 ILLUSTRATIONS AND PARTS 114 02250127 727R01 7 21 ELECTRICAL PARTS ALL MODELS...

Page 126: ...Section 7 ILLUSTRATIONS AND PARTS 120 02250136 503R02 7 23 FRAME AND PARTS...

Page 128: ...Section 7 ILLUSTRATIONS AND PARTS 122 7 24 DECAL GROUP...

Page 130: ...Section 7 ILLUSTRATIONS AND PARTS 124 7 24 DECAL GROUP...

Page 132: ...Section 7 ILLUSTRATIONS AND PARTS 126 7 24 DECAL GROUP...

Page 134: ...Section 7 ILLUSTRATIONS AND PARTS 128 7 24 DECAL GROUP...

Page 136: ...Section 7 ILLUSTRATIONS AND PARTS 130 7 25 DECAL LOCATIONS 02250136 067R03...

Page 138: ...Section 7 ILLUSTRATIONS AND PARTS 132 7 25 DECAL LOCATIONS 02250136 067R03...

Page 140: ...NOTES 134...

Page 141: ......