Section 7

ILLUSTRATIONS AND PARTS

49

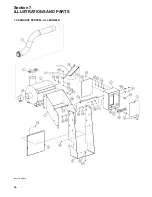

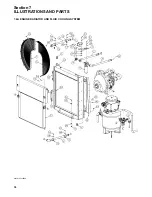

7.3 ENGINE AND COMPRESSOR MOUNTING

key

part

number

description

number

quantity

1

spacer, eng mnt cat 3406 1”

02250043-374

1

2

support, unit/eng h900/350

02250043-377

1

3

bushing, taper lock 4040 w/2.75 bore

02250069-226

1

4

coupling, drive act-6 1350/350

(I)

02250069-601

1

5

sub assembly, vlv assy 2.5 npt x 2.5 4bsf disch

(II)

02250081-044

1

6

panel, heat shield

02250117-891

1

7

belt, set cat 4n-6423 (.57:1)

02250121-879

1

8

tube, radiator upper 900xh-1900

02250128-894

1

9

spacer, fan cat c15 49.63” fan

02250133-590

1

10

clamp, hose 3”

040343

4

11

clamp, hose 13/16” to 1-1/2”

040513

1

12

draincock, 1/2”

041063

1

13

switch, temp-265f 54” los nc

045641

1

14

gasket, 2-1/2” flange

046053

1

15

washer, snubbing 1” bolt

222607

4

16

adapter, eng/compr 900xh

231811

1

17

switch, temperature nc 250deg f

242257

1

18

hose, med press .25 x 30” lg

249604-019

1

19

isolator, vibration 500 lb. capacity

250010-330

2

20

support, front engine mnt 3408 dita

250030-568

1

21

valve, drain 1-1/8-12unf

250031-046

1

22

washer, .500 hardened

250040-099

6

23

valve, oil stop 2” sae code 61

250041-069

1

24

hose, rad upper 2-1/2 x 6”

407749

2

25

flange, thrd 2 1/2” 300# rf

820330-040

1

26

key, square cl1 5/8” x 3

821110-300

1

27

nut, hex locking 3/4-10

825512-382

2

28

nut, hex locking 1-8

825516-513

2

29

o-ring, viton 2 1/4 x 1/8”

826502-228

1

30

capscrew, hex gr8 1/2-13 x 2

827908-200

8

31

capscrew, hex gr8 5/8-11 x 1 3/4

827910-175

4

32

capscrew, hex gr8 3/4-10 x 1 1/2

827912-150

2

(I)

For maintenance on coupling, order replacement element no. 02250137-653.

(II)

For maintenance on sub-assembly valve no. 02250081-044, order repair kit no. 606208-001.

PLEASE NOTE: WHEN ORDERING PARTS, INDICATE THE SERIAL NUMBER OF COMPRESSOR

Summary of Contents for 1350XH

Page 6: ......

Page 18: ...Section 2 DESCRIPTION 12 Figure 2 3A Control System 900XH 1150XH and 1350XH Models...

Page 19: ...Section 2 DESCRIPTION 13 Figure 2 3B Control System Aftercooled Models...

Page 29: ...Section 2 DESCRIPTION 23 Figure 2 7 Wiring Diagram 02250145 161R01...

Page 30: ...NOTES 24...

Page 33: ...Section 3 SPECIFICATIONS 27 02250135 977R03 Figure 3 2 Identification Compressor Assembly...

Page 34: ...NOTES 28...

Page 38: ...NOTES 32...

Page 54: ...Section 7 ILLUSTRATIONS AND PARTS 48 02250127 622R08 7 3 ENGINE AND COMPRESSOR MOUNTING...

Page 56: ...Section 7 ILLUSTRATIONS AND PARTS 50 02250127 622R08 7 3 ENGINE AND COMPRESSOR MOUNTING...

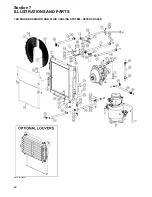

Page 58: ...Section 7 ILLUSTRATIONS AND PARTS 52 02250136 060R02 7 4 AIR INLET SYSTEM ALL MODELS...

Page 60: ...Section 7 ILLUSTRATIONS AND PARTS 54 02250136 060R02 7 4 AIR INLET SYSTEM ALL MODELS...

Page 62: ...Section 7 ILLUSTRATIONS AND PARTS 56 02250136 062R02 7 5 EXHAUST SYSTEM ALL MODELS...

Page 72: ...Section 7 ILLUSTRATIONS AND PARTS 66 02250127 633R02 7 7 ENGINE RADIATOR ASSEMBLY ALL MODELS...

Page 74: ...Section 7 ILLUSTRATIONS AND PARTS 68 7 8 AFTERCOOLER MOUNTING ALL MODELS 02250150 135R03...

Page 82: ...Section 7 ILLUSTRATIONS AND PARTS 76 02250140 983R01 7 12A INLET VALVE AND PARTS 6 5 900XH...

Page 86: ...Section 7 ILLUSTRATIONS AND PARTS 80 02250054 762R06 7 13A INLET VALVE PARTS 6 5 900XH...

Page 90: ...Section 7 ILLUSTRATIONS AND PARTS 84 02250127 667R10 7 14A DISCHARGE SYSTEM 900XH AND 1150XH...

Page 96: ...Section 7 ILLUSTRATIONS AND PARTS 90 02250148 288R01 7 14C DISCHARGE SYSTEM 1350XH AFTERCOOLED...

Page 98: ...Section 7 ILLUSTRATIONS AND PARTS 92 02250148 288R01 7 14C DISCHARGE SYSTEM 1350XH AFTERCOOLED...

Page 116: ...Section 7 ILLUSTRATIONS AND PARTS 110 02250164 870R01 7 19 MINIMUM PRESSURE CHECK VALVE...

Page 118: ...Section 7 ILLUSTRATIONS AND PARTS 112 02250136 066R00 7 20 FUEL SYSTEM AND PARTS ALL MODELS...

Page 120: ...Section 7 ILLUSTRATIONS AND PARTS 114 02250127 727R01 7 21 ELECTRICAL PARTS ALL MODELS...

Page 126: ...Section 7 ILLUSTRATIONS AND PARTS 120 02250136 503R02 7 23 FRAME AND PARTS...

Page 128: ...Section 7 ILLUSTRATIONS AND PARTS 122 7 24 DECAL GROUP...

Page 130: ...Section 7 ILLUSTRATIONS AND PARTS 124 7 24 DECAL GROUP...

Page 132: ...Section 7 ILLUSTRATIONS AND PARTS 126 7 24 DECAL GROUP...

Page 134: ...Section 7 ILLUSTRATIONS AND PARTS 128 7 24 DECAL GROUP...

Page 136: ...Section 7 ILLUSTRATIONS AND PARTS 130 7 25 DECAL LOCATIONS 02250136 067R03...

Page 138: ...Section 7 ILLUSTRATIONS AND PARTS 132 7 25 DECAL LOCATIONS 02250136 067R03...

Page 140: ...NOTES 134...

Page 141: ......